Reliable, Consistent Cleaning for your COP parts

Food and beverage manufacturers have a significant number of parts that need to be cleaned daily; each with specific needs due to varying soil levels, manufacturing processes and soil properties. And, of course, everything needs to be cleaned quickly to keep production moving. That is where cabinet washers come into play.

Sani-Matic Cabinet-Washers

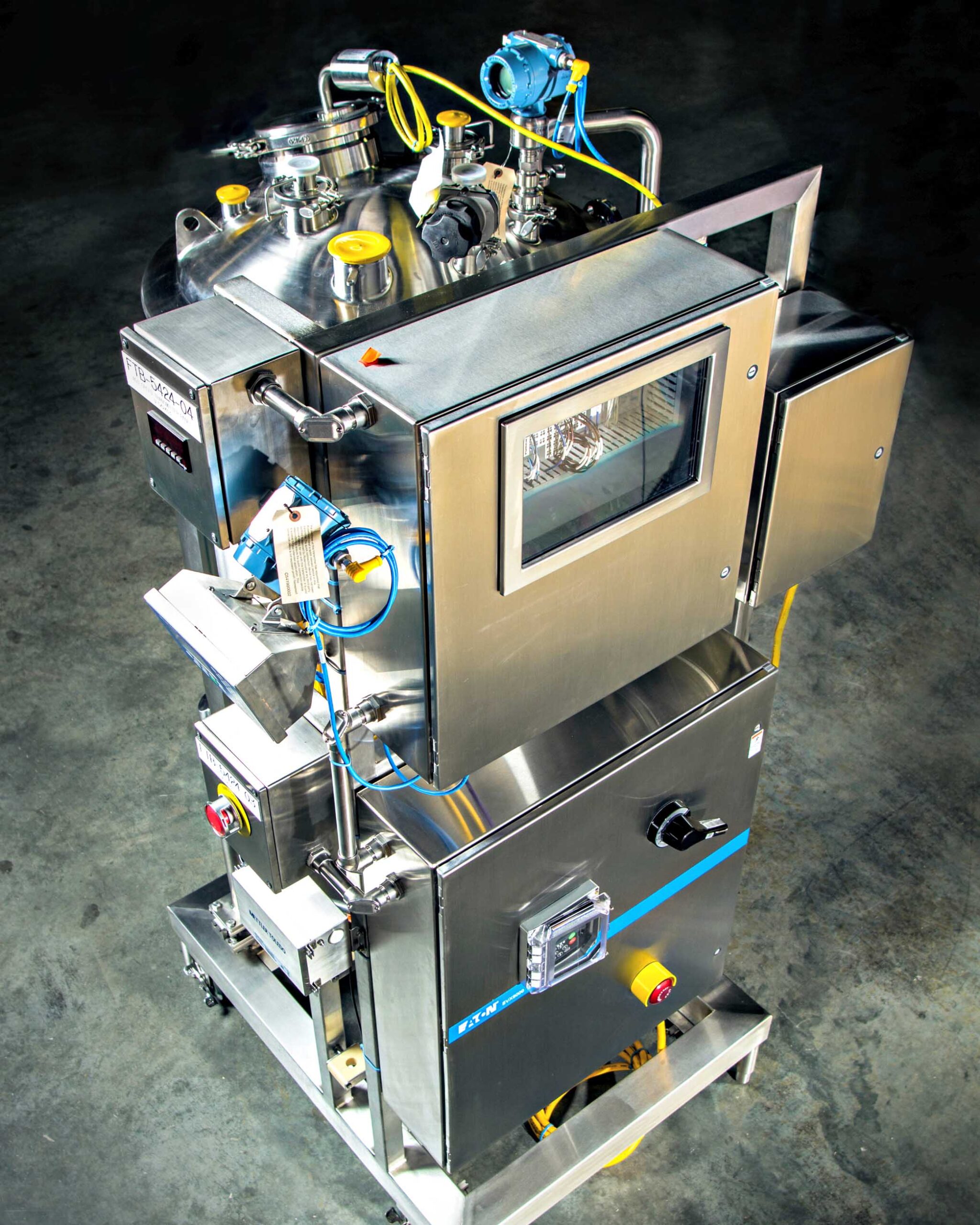

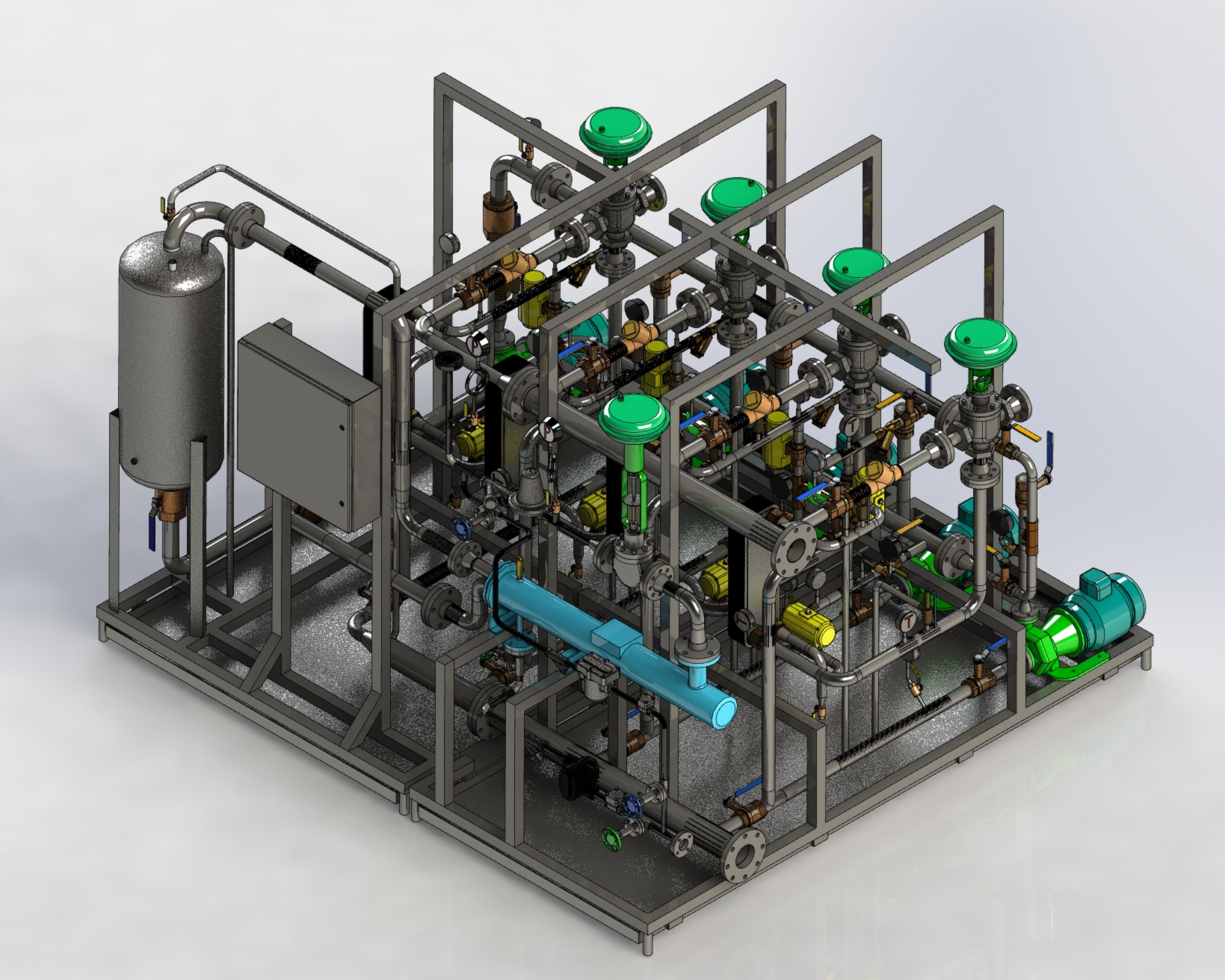

The automated Sani-Matic cabinet washers design and manufacture purpose is to address these challenges efficiently and effectively, while lowering long-term operating expenses.

Therefore each cabinet washer comes with an exclusively-designed sanitary spray assemblies that distribute cleaning solution evenly throughout the washer.

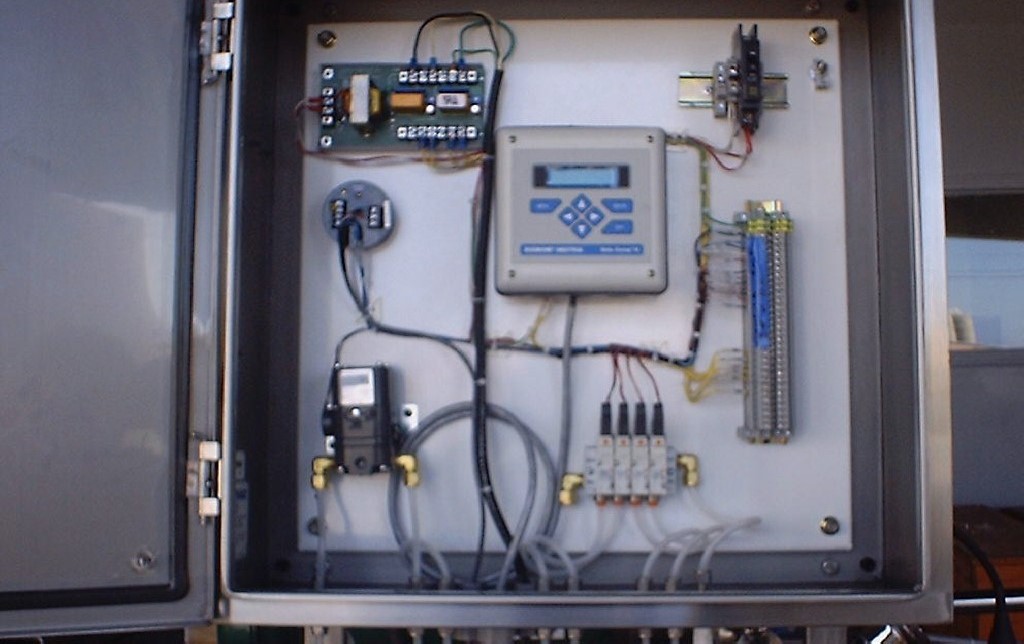

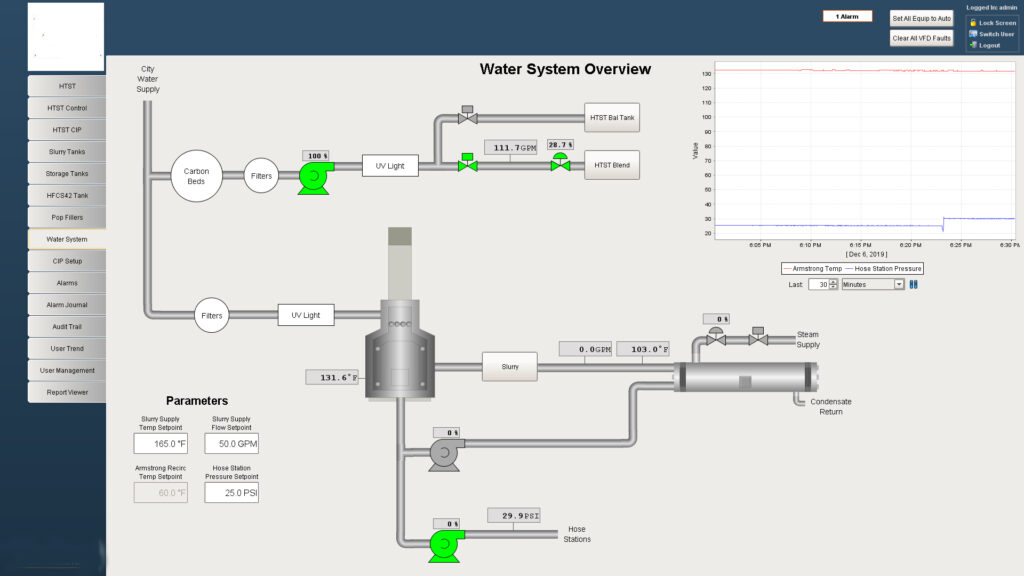

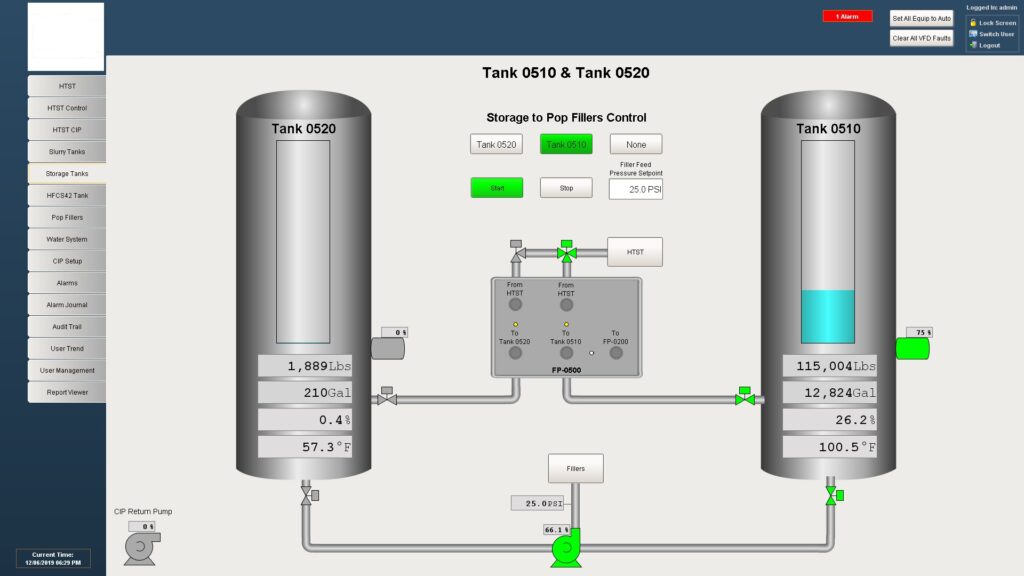

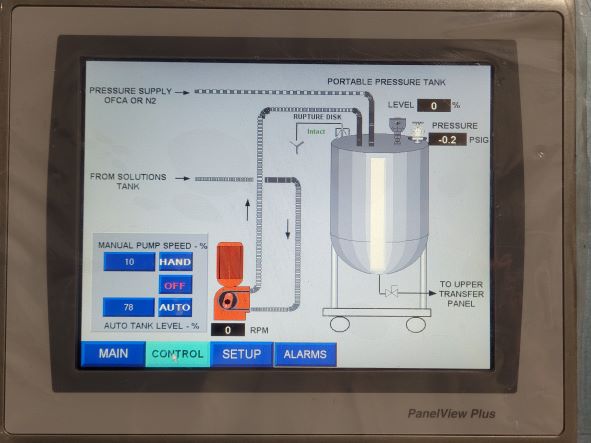

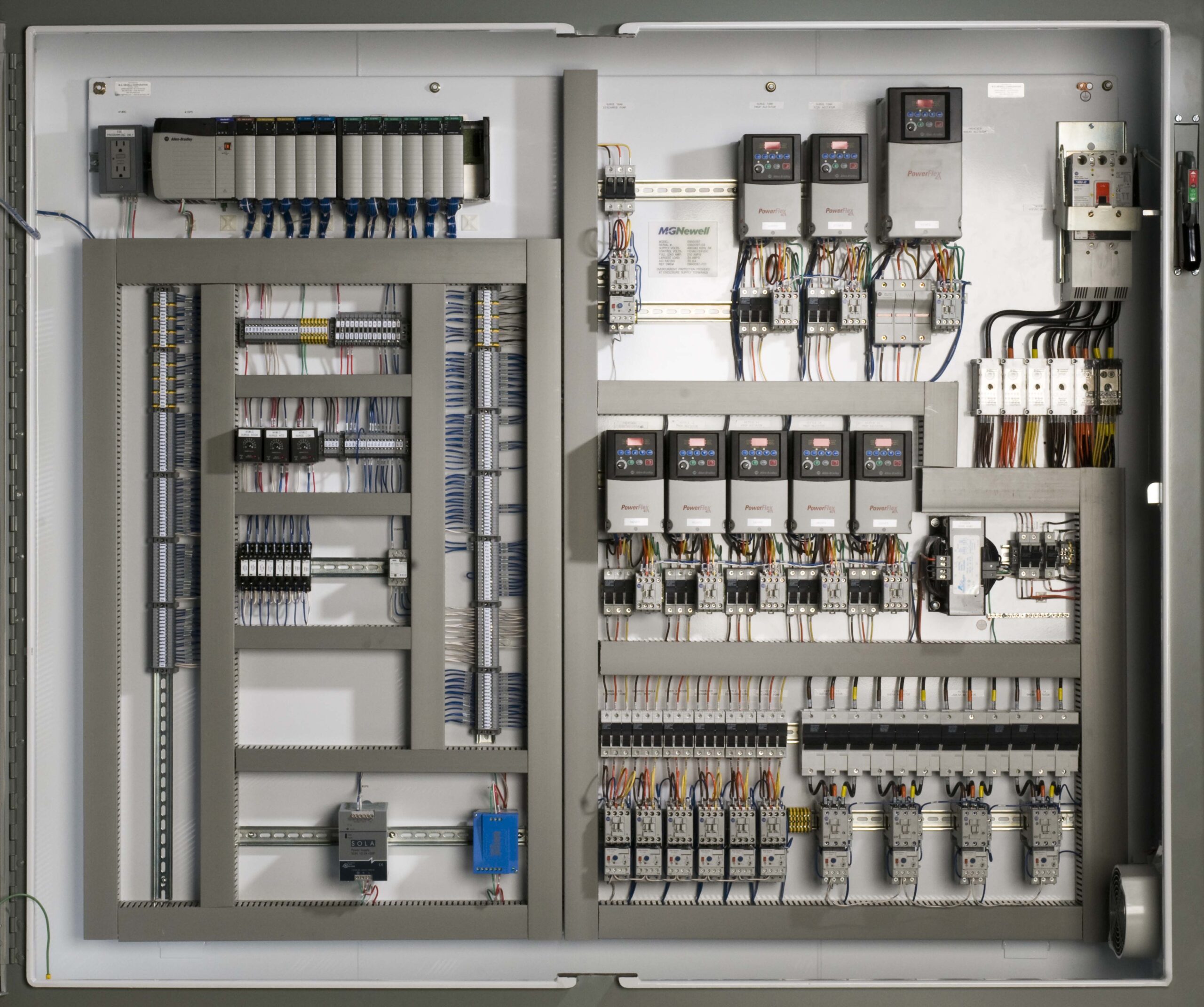

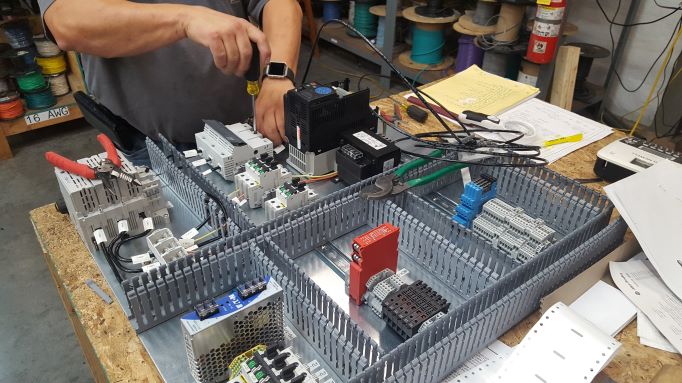

The cabinet washer’s spray arms and oscillating high-impact manifolds effectively remove difficult residues from interior and exterior product contact surfaces, while the PLC controls the cleaning cycle to ensure a repeatable and documentable process.

A complete clean, every time! That’s Cleaning Confidence!

The Scale Bucket-Piston Filler-Tray-Pallet-Bucket-Barrel-Hose-and More Washer

The Sani-Matic SaniCab P Series is an automated, versatile cabinet washer designed to improve food and beverage processors’ productivity and cleaning results for a wide variety of product contact items. These items include scale buckets or weigh hoppers, totes, barrels, piston fillers, trays, buckets, hoses, buggies, and more.

Increased Productivity and Repeatable Cleaning Results

Food and beverage manufacturers face ongoing pressure to increase productivity while also meeting the sanitation preventive controls demands of FSMA and HACCP. With SaniCabs cabinet washer’s cleaning cycles as short as 10 minutes, and therefore racks designed to optimize productivity, a sanitary design, and documentation capabilities, manufacturers can achieve both.

Easy-to-Specify

The SaniCab P Series Configured Design Offering is model key driven and accompanied by a detailed Technical Datasheet for easy specification. Also if your process requires a system outside of the pre-engineering offering, Alternative Design Requests are met with a custom-engineered solution.

Sanitary Racks Designed and Optimized for Your Process

Each food and beverage manufacturer has different process soils to remove and parts to clean.

Sani-Matic’s engineers have designed Standard Racks for common clean-out-of-place process parts such as scale buckets or weigh hoppers, 3- and 5-gallon buckets, pallets, totes, trays, and buggies.

However, they also design Custom Racks following three design tiers: Customization – Standard Rack, Custom Rack, and Custom Active Rack.

The details for the General, Standard, and Custom Racks will be in the SaniCab P Series Technical Datasheet.

Why Sani-Matic Racks and Transfer Carts?

- More Clean with One Machine. With multiple racks, operators can clean diverse process parts with one capital equipment investment.

- Efficient. Racks design is for optimized load capacity and intuitive part placement.

- Safe Transport. Transfer carts assist operators with easy and safe process part handling.

- Sanitary Design. The transfer cart has an open channel design to prevent harboring bacteria. It remains outside of the washer to prevent the floor’s bacteria from entering the washer.

If you would like more information or need a quote specific to your process, contact us at sales@mgnewell.com.