WHO WE ARE

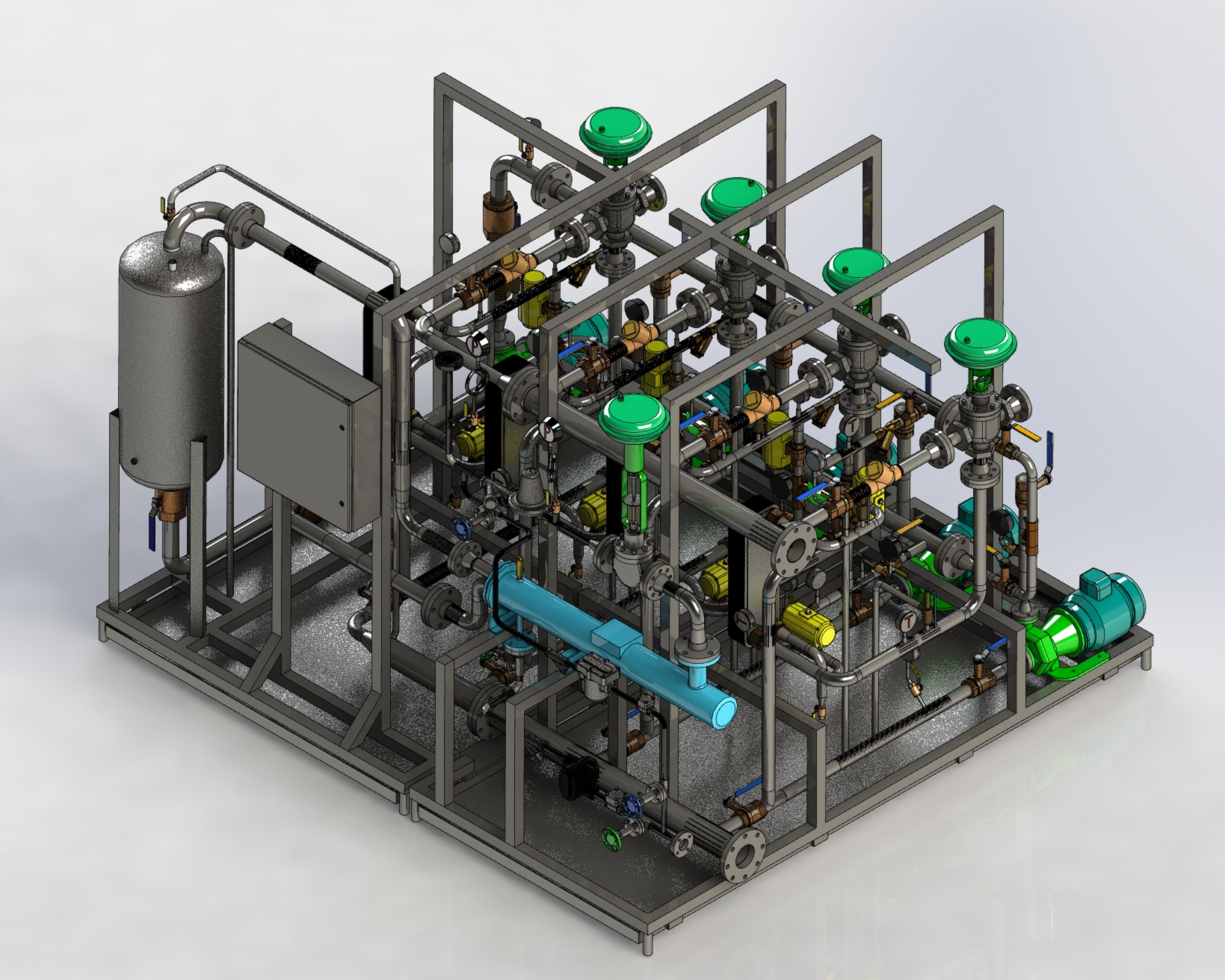

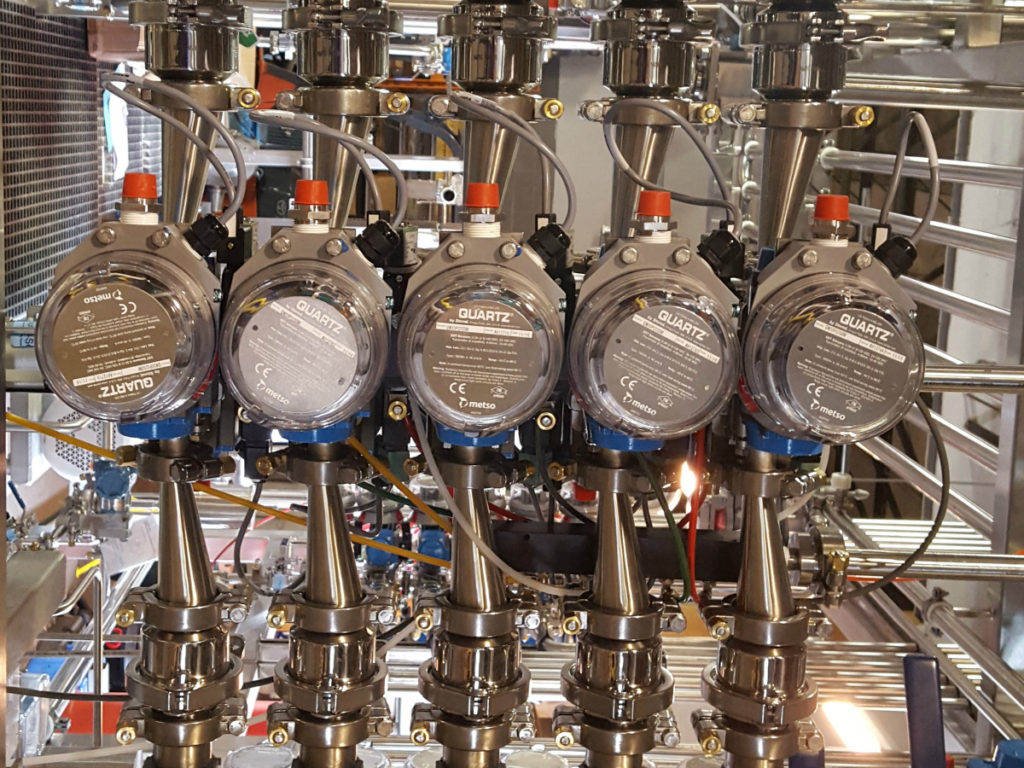

For over 130 years, M.G. Newell has remained a full-service provider of hygienic equipment for the food, beverage, dairy, pharmaceutical and personal care industries. We carry a broad range of pumps, valves, tanks, fittings, as well as other manufacturing supply needs. Our process engineers work with customers to design and fabricate cost-effective, customized systems to fit their space requirements.

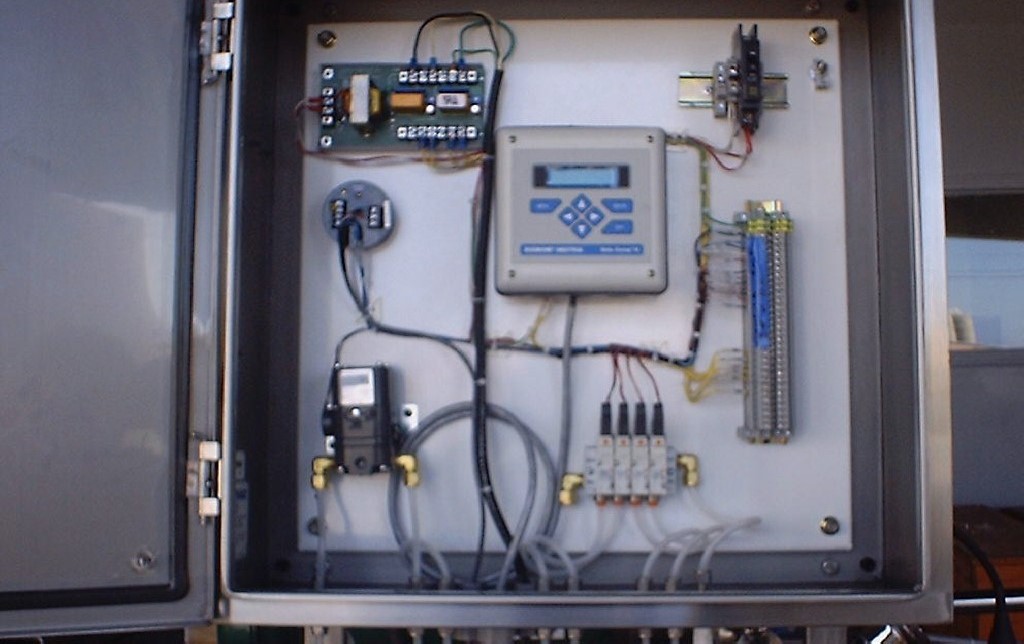

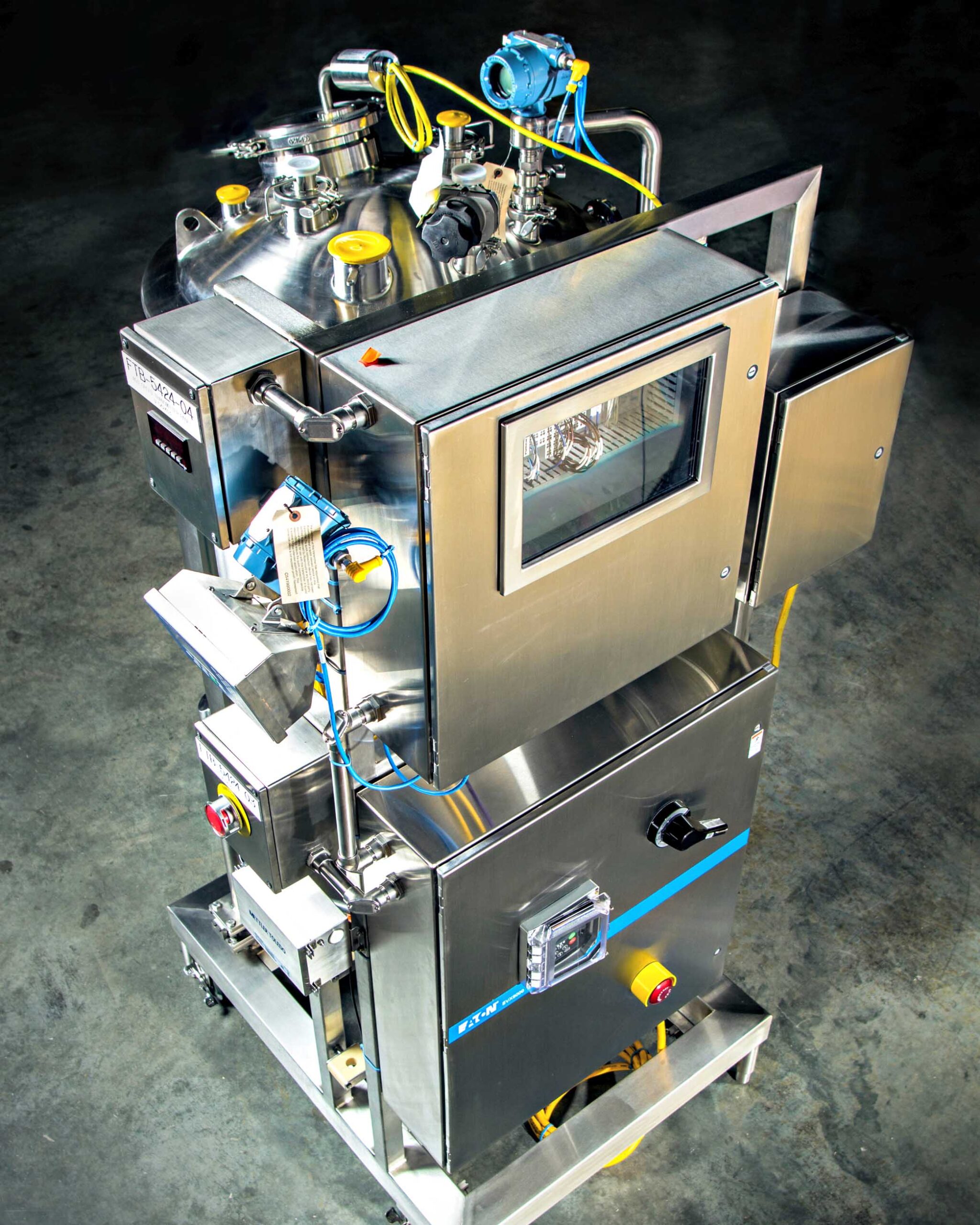

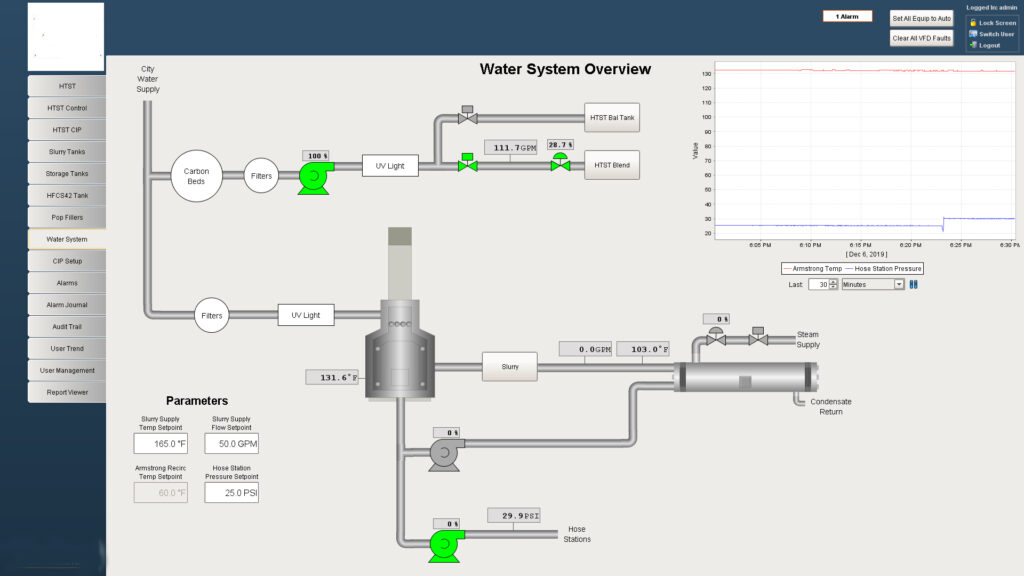

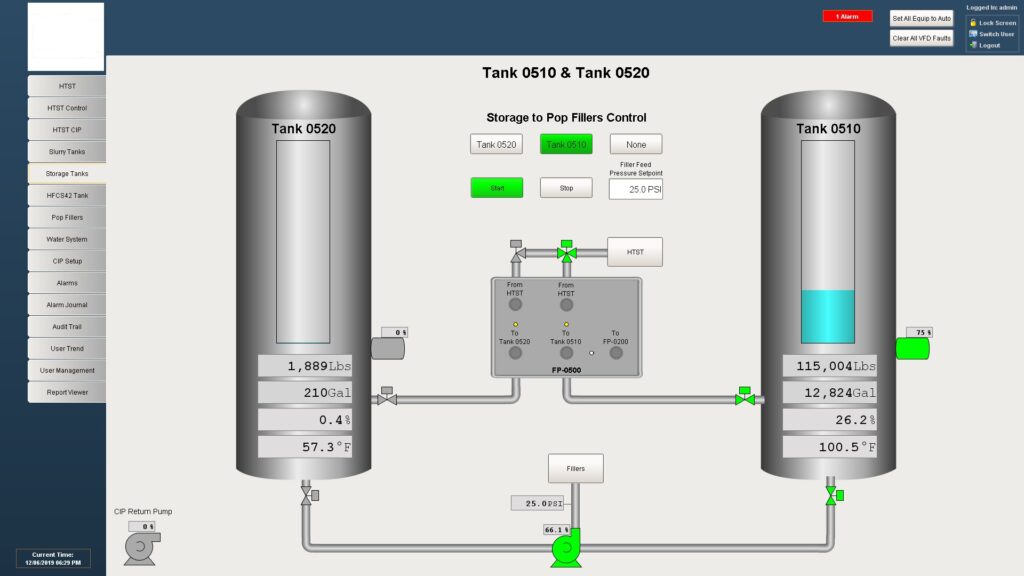

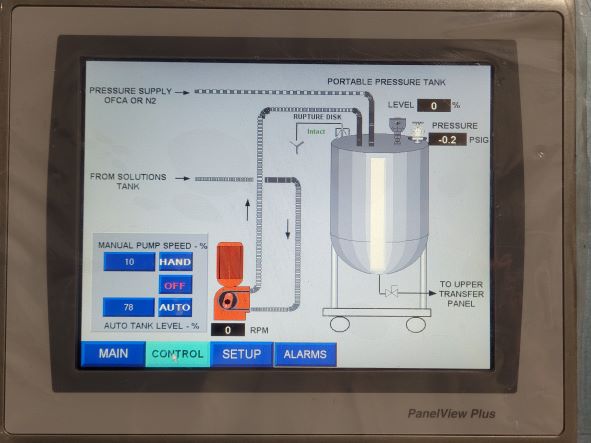

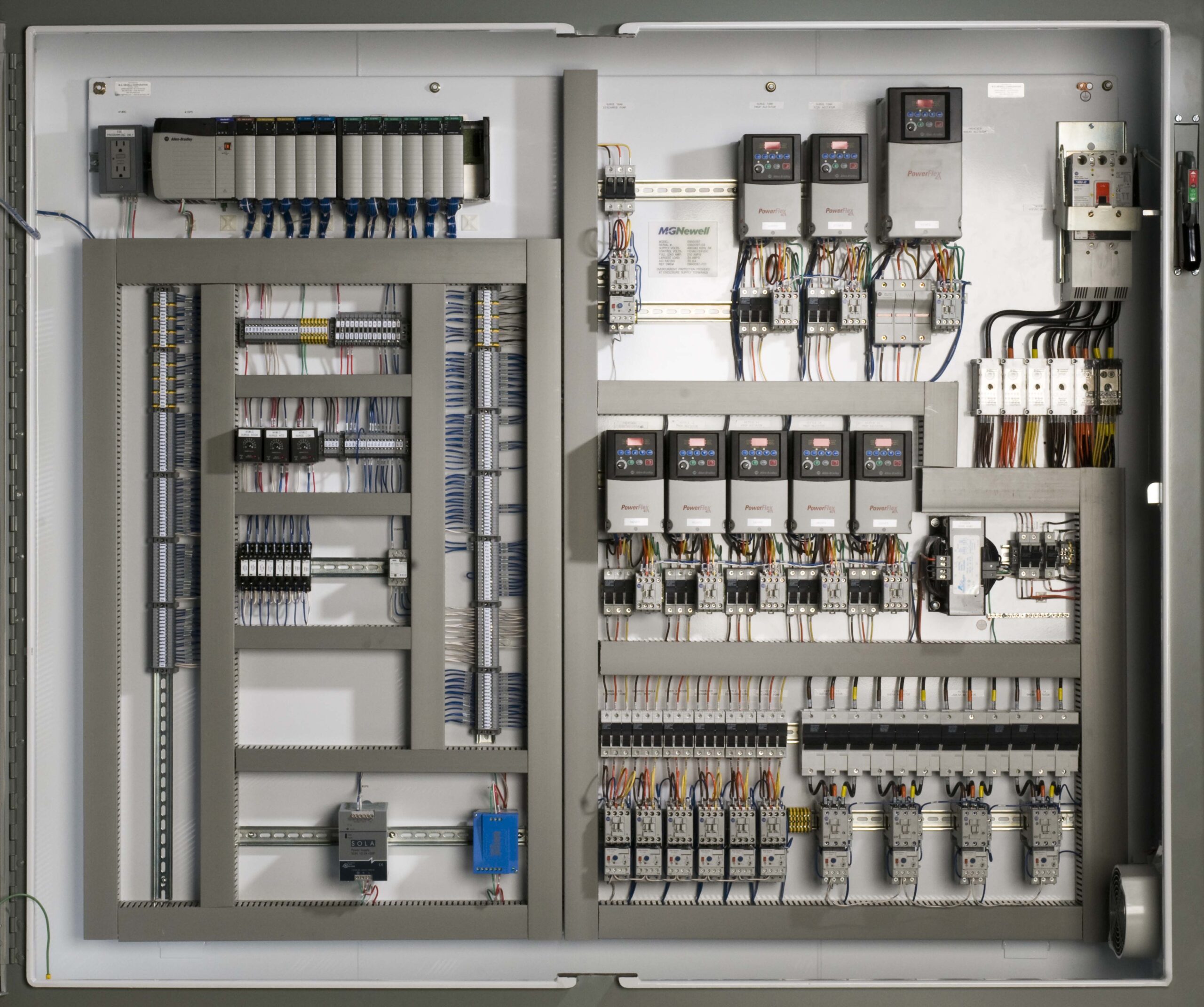

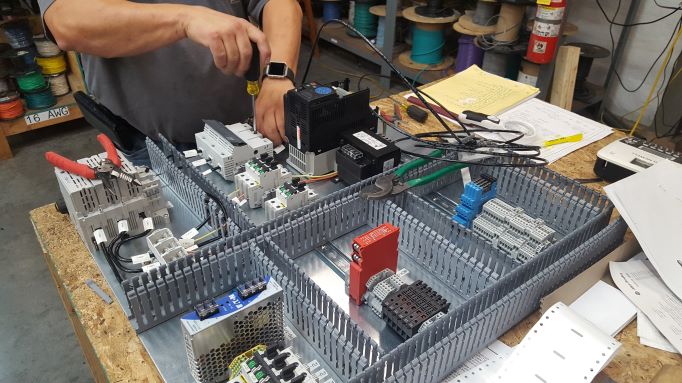

In addition to stainless steel equipment, our Newell Automation team develops full process control systems. Our controls engineers partner and work along with our process engineers to design and build batch control, cleaning or other process parameters into your plant. When M.G. Newell develops smart production systems, Newell Automation takes the process to the next level by allowing you complete and undoubtedly control at the touch of a button.

Our engineers build hygienic design into every system, from pump carts to valve clusters to batch, mixing or inline blending systems. For more about us, click the link below.

We Make It Better.

THE M.G. NEWELL DIFFERENCE

We start with a solid foundation: Service. M.G. Newell provides unparalleled service to the sanitary processing industry. Our extensive experience allows us to provide project insights with complete focus on the needs of our customers. We stay attuned to your needs throughout every phase of our relationship with you. How do we do this? We listen.

Along with a clear understanding of your business challenges and needs, we at M.G. Newell will be your partner in product solutions.

So how can We Make It Work Better for you? Whether it's calibration and maintenance of your existing equipment or perhaps you need the best welders and engineers in the industry to help upgrade your system, nevertheless we offer high quality engineering and products. Click on one of the boxes below or Contact Us by phone or email!

PRODUCT SPOTLIGHT

Overview

QUANTM is the world’s first (and only) affordable electric-operated double diaphragm (EODD) pump built to minimize energy consumption by cutting energy usage and costs by up to 80%.

QUANTM isn’t just another electric pump: it’s a game-changer. QUANTM features a revolutionary electric motor design that will reduce operational costs and keep your production lines running. It is a perfect fit for nearly any fluid application and a drop-in replacement for existing pumping technologies. Protect your bottom line by converting to a QUANTM Electric Pump.

WHO WE PARTNER WITH

As a full service supplier of systems, solutions, and components, M.G. Newell embraces each of our customers as a true partner. Your concerns are our concerns. Your problems become our problems. Ultimately, our expert solutions and service become your plan for success. Below are some of our top brand partners and a link to their thoughts on working with us. View Testimonials.

Locations

Greensboro

301 Citation Court Greensboro, NC 27409

Tel:336-393-0100

Tel:800-334-0231

Fax:336-393-0140

Louisville

4400 Bishop Lane, Suite 112 Louisville, KY 40218

Tel:502-459-7475

Tel:800-459-7475

Fax:502-459-7633

Nashville

334 Free Hill Road, Suite B Hendersonville, TN 37075

Tel:615-822-3030

Tel:855-749-4820

Fax:615-822-3031

Greensboro-Automation

7004 Cessna Drive Greensboro, NC 27409

Tel:336-393-0100

Tel:800-334-0231

Fax:336-393-0140

Corporate

P.O. Box 18765 Greensboro, NC 27419

Tel:336-393-0100

Tel:800-334-0231

Fax:336-393-0140

Locations

Corporate

336-393-0100

301 Citation Court

Greensboro, NC 27409

Greensboro

336-393-0100

7004 Cessna Drive

Greensboro, NC 27409

Louisville

502-459-7475

4400 Bishop Lane, Suite 112

Louisville, KY 40218

Nashville

615-822-3030

334 Free Hill Road

Hendersonville, TN 37075

GSO-Automation

336-393-0100

7004 Cessna Drive

Greensboro, NC 27409