Pump Problem Solving – Cavitation

For all pump application problems, cavitation is the most common issue we encounter. It occurs with all types of pumps – centrifugal, rotary or reciprocating. Cavitation is the formation of vapor cavities in a liquid – i.e. small liquid-free zones (“bubbles” or “voids”) – that are the consequence of forces acting upon the liquid. It usually occurs when a liquid is subjected to rapid changes of pressure that cause the formation of bubbles where the pressure is relatively low. These bubbles are carried along by the fluid and implode instantly when they get into areas of higher pressure.

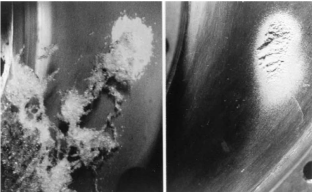

According to the Bernoulli Equation, this may happen when the fluid accelerates in a control valve or around a pump impeller. Cavitation can result in a loss of pump efficiency/flow, noise and possible damage to the pump and/or system. The vaporization itself does not cause the damage – the damage happens when the vapor almost immediately collapses when the velocity is decreased and pressure increased. When a pump cavitates, the vapor bubbles move toward the impeller where they collapse.

This causes a physical shock which creates small pits on the edge of the impeller. Each individual pit is microscopic in size, but the cumulative effect of millions of pits over a period of time can destroy a pump impeller. Cavitation can also cause excessive pump vibration which damages bearings, wearing rings and seals. Noise is typically the indication that a pump is cavitating. Other indications that can be seen include fluctuating discharge pressure, flow rate and pump motor current. Excessive pump speed and/or adverse suction conditions will probably be the cause.

microscopic in size, but the cumulative effect of millions of pits over a period of time can destroy a pump impeller. Cavitation can also cause excessive pump vibration which damages bearings, wearing rings and seals. Noise is typically the indication that a pump is cavitating. Other indications that can be seen include fluctuating discharge pressure, flow rate and pump motor current. Excessive pump speed and/or adverse suction conditions will probably be the cause.

Suggestions for avoiding or minimizing cavitation:

Use the 1.5 multiplier for suction tubing (a 2” pump should have a 3” suction tubing and reduce to 2” at the pump)

– Note – this could cause excessive pump sizing for CIP flow rate. This is only recommended when cavitation is a concern.

Use the 7 to 10 diameter rule for straight tubing. No elbows directly into the pump.

Fluid viscosity kills – stay under 5 feet per second.

Maintain a static head as high as possible.

Reduce fluid temperature, although caution is needed as this may have an effect of increasing fluid viscosity, thereby increasing pressure drop. If cavitation is a concern, it is strongly recommended that you contact an engineer to review your process.

Pressure ‘Shocks’ (Water Hammer)

The term “shock‟ is not strictly correct as shock waves only exist in gases.

The pressure shock is really a pressure wave with a velocity of propagation much higher than the velocity of the flow, often up to 1400 m/s for steel tubes. Pressure waves are the result of rapid changes in the velocity of the fluid in especially long runs of piping.

The following causes changes in fluid velocity:

• Valves are closed or opened

• Pumps are started or stopped

• Resistance in process equipment such as valves, filters, meters, etc

• Changes in tube dimensions

• Changes in flow direction

Most pressure wave problems are due to rapidly closed or opened valves. For example, when a valve is closed, the pressure wave travels from the valve to the end of the tube. The wave is then reflected back to the valve. These waves gradually weaken due to friction in the tube. Pumps, which are rapidly/frequently started or stopped, can also cause some problems. A pressure wave resulting from a pump stopping is more damaging than for a pump starting due to the fact that a large change in pressure continues much longer after a pump is stopped compared to a pump starting. A pressure wave induced as a result of a pump stopping can result in negative pressure values in long tubes, i.e. values close to the absolute zero point which can result in cavitation if the absolute pressure drops to the vapor pressure of the fluid. When designing pipework systems it is important to keep the natural frequency of the system as high as possible by using rigid pipework and as many pipe supports as possible.

Effects of pressure waves:

• Noise in the tube

• Damaged tube

• Damaged pump, valves and other equipment

• Cavitation.

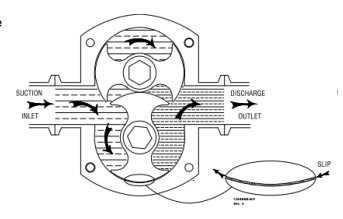

Slip

Slip occurs in PD pumps when fluids passes from the discharge side back to the inlet side of the pump through the pump clearances. It is the difference between the theoretical displacement and the actual displacement. Slip is caused by three factors:

Viscosity – Slip will decrease as fluid viscosity increases; the

reduction eventually reaches a point called “zero slip”.

Pressure – Slip will increase with pressure increases

Clearance – Increased clearances will result in greater slip.

The size and shape of the rotors will be a factor.