A pet food manufacturer that we work with typically processes a number of meat slurries made of white fish, lamb, chicken, duck, turkey, etc. Due to the different meats and the fact that these slurries are kept in tank hoppers at 40 degrees F or colder, the viscosity of each slurry created pumping issues. The customer had used PD pumps with some success, but they were having to replace or repair these pumps frequently. They wanted a different solution that would minimize maintenance and allow them to pull the meat slurry out of the hoppers. The customer had used PD pumps with some success, but they were having to replace or repair these pumps frequently. They wanted a different solution that would minimize maintenance and allow them to pull the meat slurry out of the hoppers.

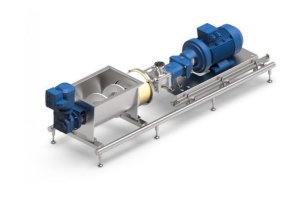

The M.G. Newell account manager thought that a twinscrew pump would be a good solution. In reviewing the case study about The Chocolate Situation, he contacted the pump manufacturer. They brought in a demo pump to try on the meat slurry. The twin screw pump was able to push the slurry through the 4” line. It was also able to suck the slurry from the hopper.

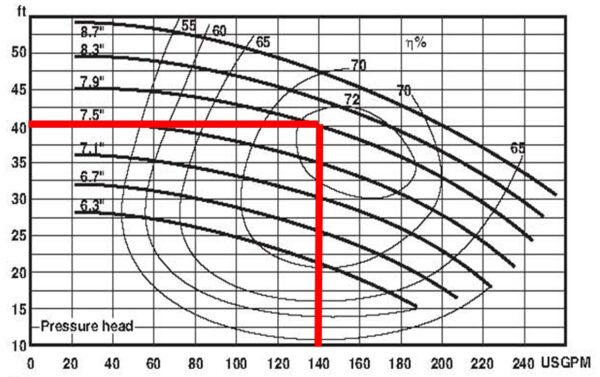

After the trial, the customer upsized to a 5” inlet on the pump to further improve the suction capabilities on this high-viscous slurry. The pump was sized to reflect a flow rate of 18 gpm with a 10HP gear reducer. This sizing decision, as seen in The Chocolate Situation – Case Study, will pump a meat slurry up to 23,000 cps. The customer is currently evaluating the pump on one of their 4 hoppers. If the pump continues to perform, they’ll be putting a twin-screw pump on the other 3 hoppers as well. Want to learn more about how twin-screw pumps work? Are they the right solution for your process? Click: Twin-Screw Pumps