Understanding Centrifugal Pump Curves

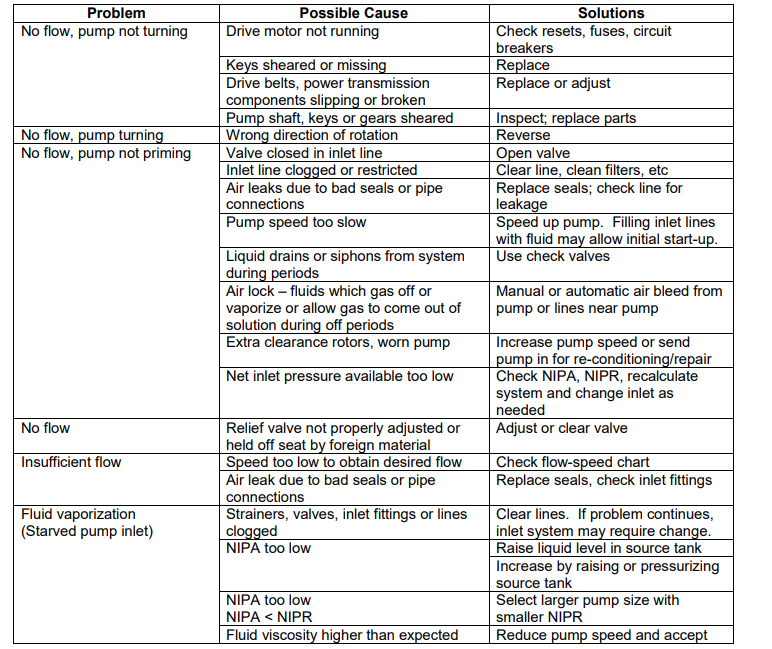

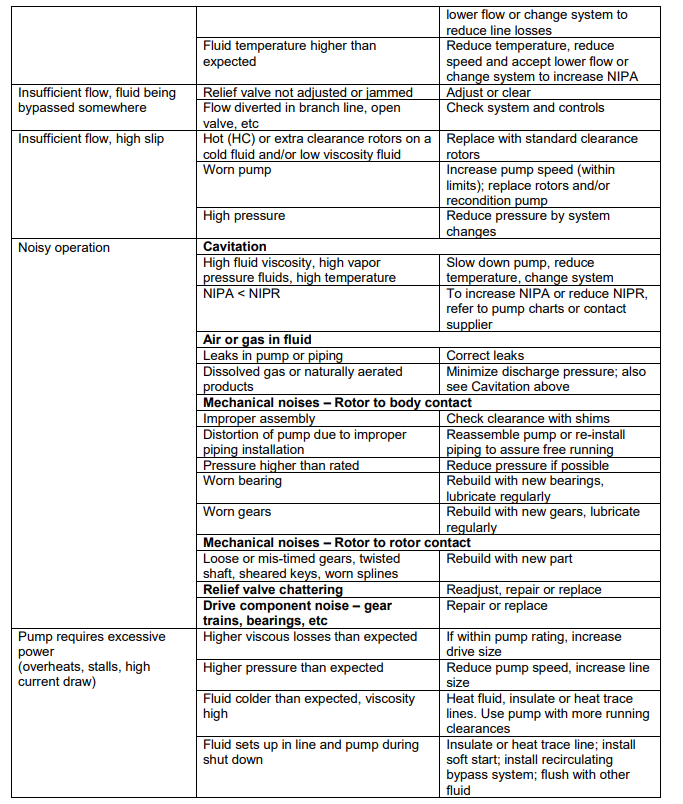

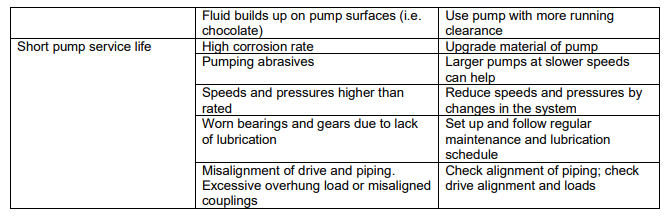

Once a pump is properly selected and installed in a system, operation should be trouble free. However, in existing systems, or as pump and system conditions change, problems may develop. Following are some troubleshooting hints to help identify and solve problems.

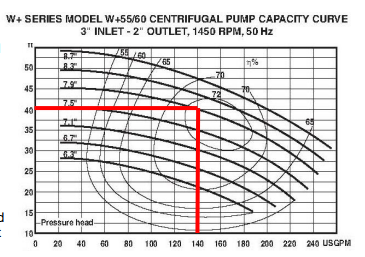

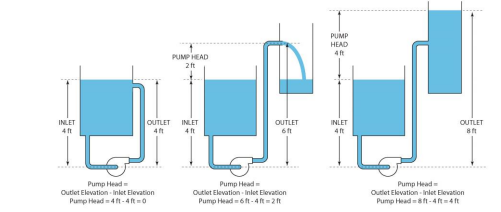

When selecting a centrifugal pump, one should match the performance of the pump to that needed by the system. To do

that, an engineer would refer to a pumps composite curve. A typical composite curve includes the pump performance

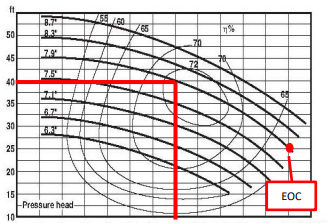

curves, horsepower curves and NPSH required. A pump performance curve indicates how a pump will perform in regards to pressure head and flow. A curve is defined for a specific operating speed (rpm) and a specific inlet/outlet diameter. In our example below, these curves show the performance at 1450 rpm for a 3” inlet/2” outlet. Several curves on one chart indicate the performance for various impeller diameters. In the example below, the impeller size ranges from 6.3” to 8.7”. These curves also tell you the possible conditions that the pump could modify to meet

for various impeller diameters. In the example below, the impeller size ranges from 6.3” to 8.7”. These curves also tell you the possible conditions that the pump could modify to meet

in the future by installing a different impeller size. You indicate flow on the x-axis while pressure/head is indicated on the y-axis. In this example, if pumping

against a head of 40 ft using an impeller size of 7.9”, you could pump at a rate of 140 gallons per minute. Typical centrifugal pumps will show an increased flow rate as head pressure decreases. The curve also shows the shut off head or the head that the

pump would generate if operating against a closed valve. In our same example, the shutoff for the 7.9” impeller is 45 ft of head. The pump performance curve also provides efficiency curves. These efficiency curves intersect with the head-flow curves and we label them with percentages. The efficiency varies throughout the operating range. In our same example with the 7.9” impeller, we can see that at 140 gallons per minute, the pump is operating at 72% efficiency.

Some curves will also mark the Best Efficiency Point (B.E.P.). This is the point on a pump’s performance curve that corresponds to the highest efficiency and is usually between 80-85% of the shutoff head. At this point, the impeller is subjected to minimum radial force promoting a smooth operation with low vibration and noise. Pumps run best at or

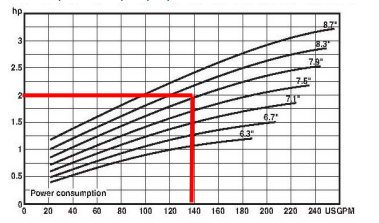

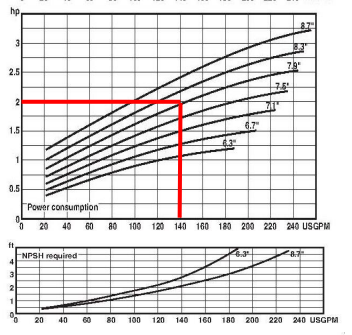

near BEP. Operating the pump outside of the recommended range will most likely shorten the pump life. BHP (brake horsepower) curves indicate the horsepower required to operate a pump at a given point on the performance curve. The lines on the horsepower curve correspond to the performance curves above them and, like the head-flow curve, the different lines correspond to different impeller sizes. This information is useful to ensure that the selected motor is the correct size and is also used when calculating power consumption costs. If we take our same example of a flow of 140 gpm using the 7.9” impeller, the power demand is 2 hp.

When sizing a motor, the total current and future demand should be considered to make sure that the motor is the correct size. The motor is typically sized not at the peak efficiency point but by the maximum power draw that will be needed. It is common practice to size the motor for the End of Curve (EOC) horsepower requirements. In the example shown, even though 2 hp is required for a flow of 140 gpm with 40 ft head, the end of curve horsepower requires a 2.5 hp motor be used.

be considered to make sure that the motor is the correct size. The motor is typically sized not at the peak efficiency point but by the maximum power draw that will be needed. It is common practice to size the motor for the End of Curve (EOC) horsepower requirements. In the example shown, even though 2 hp is required for a flow of 140 gpm with 40 ft head, the end of curve horsepower requires a 2.5 hp motor be used.

NPSHr Curve

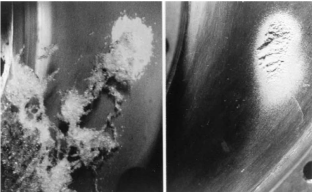

The 3rd part of the pump curve is the Net Positive Suction Head Required (NPSHr) curve. The NPSHr curve provides information about the suction characteristics of the pump at different flows. The x-axis is still measured in flow units (gallons per minute), but the y-axis is now measured in feet of NPSHr. Each point along the curve identifies the NPSHr required by the pump at a certain flow to avoid cavitation issues that would be damaging to the pump and would have a negative impact on overall pump performance. In other words, the NPSH available must be greater than the NPSHr to avoid cavitation. Looking back at our example design flow of 140 gallons per minute, we can see that this pump will require approximately 2.5 ft of NPSHr at that condition. Generally speaking NPSHr does not vary dramatically between variations in impeller trim which is why we do not see separate curves for the minimum and maximum impeller trims. Those curves are actually present, but they are overlaid by the designtrim NPSHr curve.

different flows. The x-axis is still measured in flow units (gallons per minute), but the y-axis is now measured in feet of NPSHr. Each point along the curve identifies the NPSHr required by the pump at a certain flow to avoid cavitation issues that would be damaging to the pump and would have a negative impact on overall pump performance. In other words, the NPSH available must be greater than the NPSHr to avoid cavitation. Looking back at our example design flow of 140 gallons per minute, we can see that this pump will require approximately 2.5 ft of NPSHr at that condition. Generally speaking NPSHr does not vary dramatically between variations in impeller trim which is why we do not see separate curves for the minimum and maximum impeller trims. Those curves are actually present, but they are overlaid by the designtrim NPSHr curve.

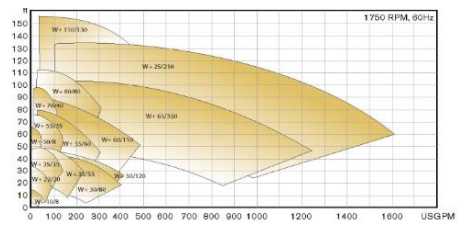

Composite or Quick Selection Curve

Often, an entire line of pumps of one design can be shown in a composite curve to give a complete picture of the available head and flow. These charts provide flow, head and pump size only. For more specifics, you must then refer to the specific performance curve for impeller diameters, efficiency and other details.

be shown in a composite curve to give a complete picture of the available head and flow. These charts provide flow, head and pump size only. For more specifics, you must then refer to the specific performance curve for impeller diameters, efficiency and other details.

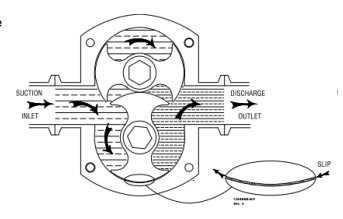

and outlet hose sizes match the size of the

and outlet hose sizes match the size of the

missing preventive maintenance steps. The pumps were able to perform, but damage was occurring causing inefficiencies and expense in the upkeep.

missing preventive maintenance steps. The pumps were able to perform, but damage was occurring causing inefficiencies and expense in the upkeep.

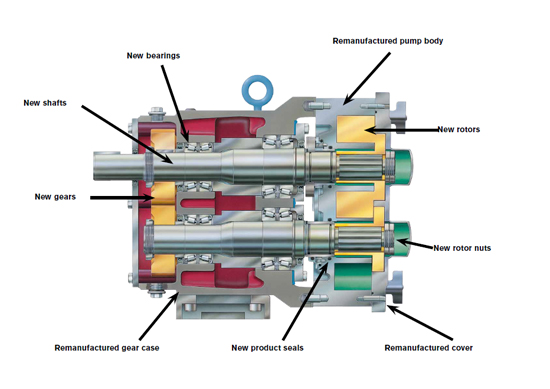

Therefore, when complete the pump is back to its original performance specifications and has a new 1-year warranty from SPX Flow. Due to the new oversized body, standard rotors are not used due to potential damage or failure of the pump. Also a pump can be remanufactured two times in its lifetime. Therefore cost of a remanufactured pump is approximately 75% of the cost of a new pump.

Therefore, when complete the pump is back to its original performance specifications and has a new 1-year warranty from SPX Flow. Due to the new oversized body, standard rotors are not used due to potential damage or failure of the pump. Also a pump can be remanufactured two times in its lifetime. Therefore cost of a remanufactured pump is approximately 75% of the cost of a new pump. microscopic in size, but the cumulative effect of millions of pits over a period of time can destroy a pump impeller. Cavitation can also cause excessive pump vibration which damages bearings, wearing rings and seals.

microscopic in size, but the cumulative effect of millions of pits over a period of time can destroy a pump impeller. Cavitation can also cause excessive pump vibration which damages bearings, wearing rings and seals.

After one month, the customer loves the new process improvements. They are maintaining a more consistent flow rate of 80-110 gpm and lower pressures of 60 psi. Production increased by 26% with more consistent product and a quieter production area. Maintenance and downtime decreased by 30%.

After one month, the customer loves the new process improvements. They are maintaining a more consistent flow rate of 80-110 gpm and lower pressures of 60 psi. Production increased by 26% with more consistent product and a quieter production area. Maintenance and downtime decreased by 30%.