Safer Wash Down Stations – Case Study

A snack company in Georgia uses steam-injected wash down stations in their plant.

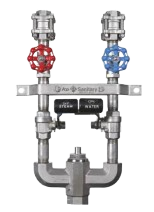

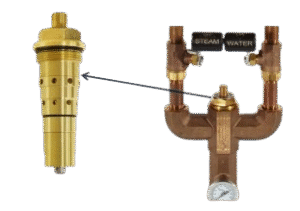

For over 20 years, they have used these steam-heated water hoses to clean equipment, walls, floors, and ceilings in the plant, along with semi-CIP systems and adjacent high pressure hoses. Their biggest pain point with their current system was that the steam would bore out the inner working components in the washdown system. Safety had become an issue. The needle valves, once bored out, would not fall back into the saddle correctly. Once that occurred, a steam backdraft was created which would come out of the spray nozzle. These bursts of steam and extremely hot water were a huge safety risk for their associates. Casey O’Rear, our account manager in GA, listened to their concerns and decided to present the Ace Sanitary Silent Type Venturi Mixer (STVM) wash down station to the Safety Manager. The STVM uses a venturi mixing valve that combines steam and water for a constant stream at the operator’s set temperature. He brought in a sample that showed how easy it is to remove and replace the patented venturi cartridge and illustrated the safety shutoff feature if the water exceeds the factory set temp.

steam would bore out the inner working components in the washdown system. Safety had become an issue. The needle valves, once bored out, would not fall back into the saddle correctly. Once that occurred, a steam backdraft was created which would come out of the spray nozzle. These bursts of steam and extremely hot water were a huge safety risk for their associates. Casey O’Rear, our account manager in GA, listened to their concerns and decided to present the Ace Sanitary Silent Type Venturi Mixer (STVM) wash down station to the Safety Manager. The STVM uses a venturi mixing valve that combines steam and water for a constant stream at the operator’s set temperature. He brought in a sample that showed how easy it is to remove and replace the patented venturi cartridge and illustrated the safety shutoff feature if the water exceeds the factory set temp.  The Safety Manager was very impressed with the safety features inherent in the STVM washdown station. As an added bonus, he was also impressed with the ease of cleaning and switching out the cartridge. The existing washdown system had over 36 internal parts to replace. The STVM system has one cartridge to replace and change out only takes a wrench and a few minutes. The customer only needs to keep one extra cartridge on the shelf – a huge improvement to increase their uptime. Currently they have a trial unit on the wall and want to replace all of their old wash down units currently in the plant. Eliminating a safety issue and making maintenance easier – that’s how We Make It Work Better and how We Make It Work Safer!

The Safety Manager was very impressed with the safety features inherent in the STVM washdown station. As an added bonus, he was also impressed with the ease of cleaning and switching out the cartridge. The existing washdown system had over 36 internal parts to replace. The STVM system has one cartridge to replace and change out only takes a wrench and a few minutes. The customer only needs to keep one extra cartridge on the shelf – a huge improvement to increase their uptime. Currently they have a trial unit on the wall and want to replace all of their old wash down units currently in the plant. Eliminating a safety issue and making maintenance easier – that’s how We Make It Work Better and how We Make It Work Safer!