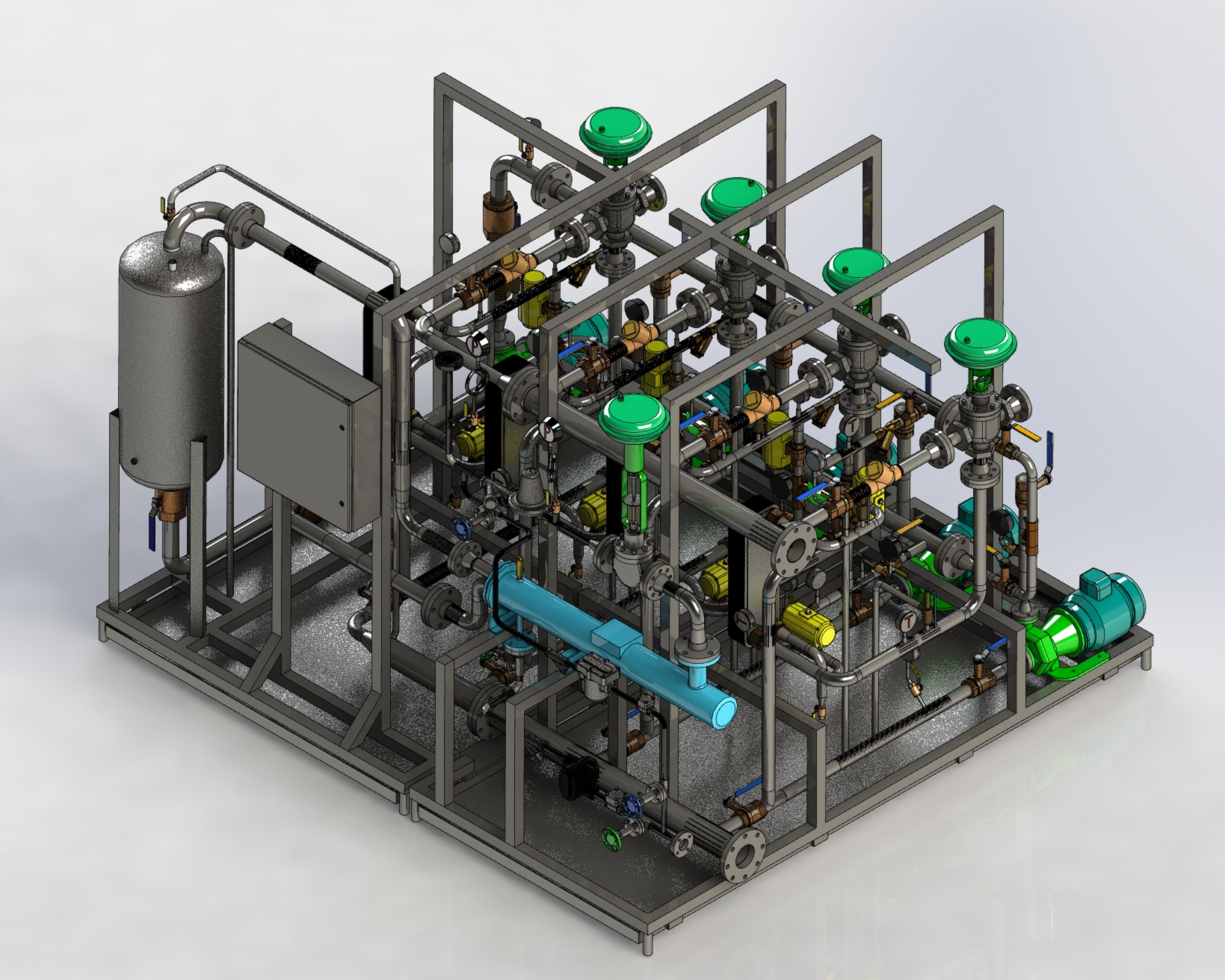

A lot goes into creating and maintaining a sanitary process, regardless of whether you are in food, beverage or pharmaceutical manufacturing. The requirements to meet 3A, FDA and other sanitary guidelines are especially demanding. Everything that the product touches, from pumps to tanks to piping, it is engineered to eliminate crevices that can create and harbor bacteria. Let’s tip our hat to the sanitary fitting, that is definetely one of the most useful pieces of equipment in your plant.

Sanitary Fittings

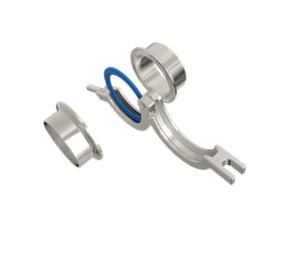

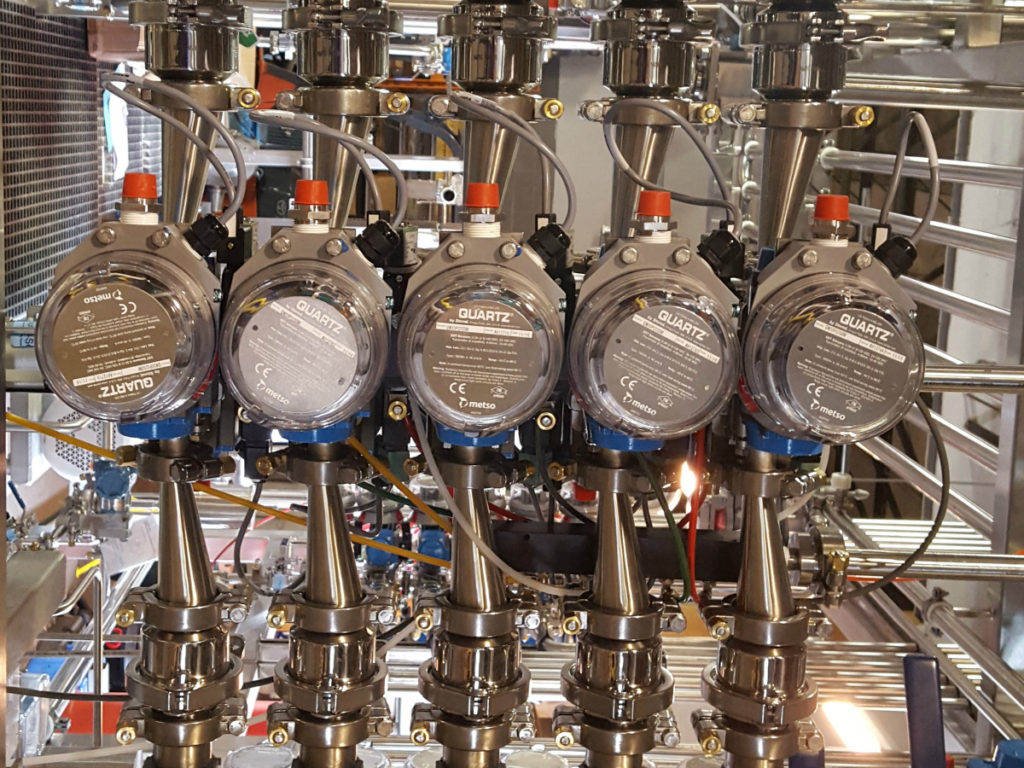

A sanitary fitting connects different sections of your process – piping to pumps to heat exchangers and lastly to tanks. A sanitary fitting is 2 ferrules, a gasket and a tri-clamp to hold them together. A groove on the face of the ferrule provides a seat for the gasket. The clamp provides the mechanical force to compress the gasket between the 2 ferrules. Our hand tightens the clamp and we use torque tools to ensure a constant amount of force and eliminate over-tightening.

In sanitary processing, these fittings are more popular because they are easy to assemble, extremely easy to clean, leak-free and, when assembled correctly, have no small nooks or crannies to harbor bacteria.

The clamped union is the critical element for evaluating pipe pressure capacity. Be certain your pressure ratings are for the union – not just the clamp.

Clamp Fittings

Clamp style fittings are most popular because they offer easy assembly and breakdown of process lines and equipment. They are available in 304 and 316L stainless steel in sizes ½” through 12”.

Weld Fittings

Weld fittings is what we use are on permanent installations where process piping and equipment can be cleaned in place (CIP) and removal of the system components is not required. We offer weld fittings in nominal tube sizes from ½” through 8” in both 304 and 316L stainless steel. Uniform wall thickness for ½” through 3” sizes measures 0.065. In 4” size, wall thickness measures 0.083. In both 6” and 8” sizes, wall thickness measures 0.109. It meets all 3A requirements.

Bevel Seat Fittings

We use bevel seat fittings on process equipment and piping to ensure rigidity of the system which is extremely important. Bevel seat unions consist of a threaded bevel ferrule mated with a plain bevel ferrule. We offer both in 304 or 316L stainless steel. Bevel seat fittings meet all 3A requirements and are available in 1” through 4” sizes.

Gasket Selection

An again, 2 ferrules, a gasket and a clamp make up the tri-clamp fittings. Gasket selection is key to ensuring a leakproof connection. The most common gasket materials are:

- BUNA – nitrile rubber (NBR); a copolymer of butadiene and acrylonitrile

- EPDM – ethylene propylene diene rubber

- FPM – flourinated propylene monomer, commonly sold under the trade name Viton®

- PTFE – polytetrafluoroethylene elastomer, commonly sold under the trade name Teflon®

For additional information on gaskets, check out our Elastomer Compability Guide and our Basic Elastomer Characteristics Guide.

Before tightening the clamp, make sure the gasket is seated properly into the seats of both ferrules. Misalignment of the gasket is one of the main causes of leaks in tri-clamp fittings.

Check out our White Paper – An Overview of Sanitary Fittings – for more information or visit one of the links below.