Pump Selection Criteria

For sanitary processing, quick and efficient cleanability is critical when choosing a pump. To ensure a hygienically and microbiologically perfect condition of the final product, high standards apply to centrifugal and PD pumps with regard

to hygiene and cleaning requirements. The surface finish influences the cleanability of pump parts. Cleaning times will decrease with improved surface finishes. Pumps for food, beverage or pharmaceutical industries are constructed of 316L stainless steel or alloys which provide a homogenous, pore-free surface. The product chamber should have no gaps or dead ends. Seal rings clamp in a way that they clean by the CIP solution. Non-metallic seals are typically made of NBR, EPDM, PTFE or FPM.1

The main purposes for creating sanitary design in pumps are to:

· make sanitation programs faster;

· make sanitation programs more efficient;

· make sanitation programs more economical;

· help prevent product adulteration;

· help satisfy regulatory requirements;

· help satisfy consumer/customer audits, demands and requirements.

Additionally, accrediting organizations, such as 3A, EHEDG, and the FDA, publish guidelines meant to specify the

technical requirements of pumps and other processing equipment. Full guidelines can be found on these organizations

websites.

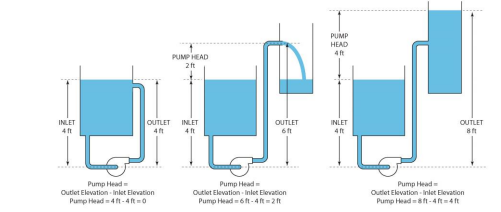

Pump Specifications and Selection

Pumps are commonly rated by horsepower, capacity or flow rate (US gallons per minute), outlet pressure (defined as meters or feet of head), and inlet suction (defined as suction meters or feet of head). The head can be simplified as the number of feet or meters the pump can raise or lower a column of water at atmospheric pressure.

Total Suction Head

![]()

where:

hs = static suction head

> 0 for flooded section

< 0 for flooded section

hfs = pressure drop in suction line

ps > 0 for pressure

ps < 0 for vacuum

ps = 0 for open tank

NBR – nitrile rubber; copolymer of butadiene and acrylonitrile; EPDM – Ethylene propylene diene rubber; a terpolymer of ethylene,

propylene and a diene-component; FPM – fluorinated propylene monomer; commonly sold under the trade name Viton®; PTFE –

polytetrafluoroethylene elastomer; commonly sold under the trade name Teflon®

Total Discharge Head

![]()

where:

ht = static discharge head

hft = pressure drop in discharge line

pt > 0 for pressure

pt < 0 for vacuum

pt = 0 for open tank

Total Head

![]()

where:

Ht = total discharge head

Hs = total suction head

From an initial design point of view, engineers often use a quantity termed the specific speed to identify the most suitable pump type for a particular combination of flow rate and head. Therefore, to ensure you choose the right pump for the application, the following is a list of questions you will need to answer.

Material Properties

What is the material being pumped?

What is the material viscosity?

What is the material density or specific gravity?

What is the particle size?

What is the temperature of the material?

Is the material abrasive?

Process Conditions

What is the desired flow rate?

Where is the feed tank relative to the pump?

What is the suction lift distance?

What is the head pressure?

What is the discharge distance?

What is the inlet and outlet hose diameter?

Other Considerations

What certification is required (FDA, 3-A, EHEDG)?

Will COP or CIP use it?

What is the desired price range?

What is the pressure of the shop air?

Who will clean and service the pump?

What special applications to consider?

With these questions and answers in hand, you can discuss the best pump choice with one of our engineers.

missing preventive maintenance steps. The pumps were able to perform, but damage was occurring causing inefficiencies and expense in the upkeep.

missing preventive maintenance steps. The pumps were able to perform, but damage was occurring causing inefficiencies and expense in the upkeep.

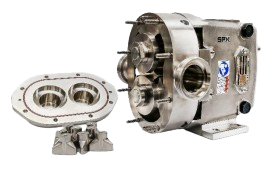

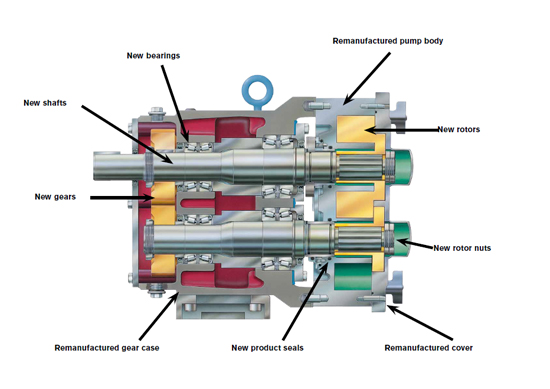

Therefore, when complete the pump is back to its original performance specifications and has a new 1-year warranty from SPX Flow. Due to the new oversized body, standard rotors are not used due to potential damage or failure of the pump. Also a pump can be remanufactured two times in its lifetime. Therefore cost of a remanufactured pump is approximately 75% of the cost of a new pump.

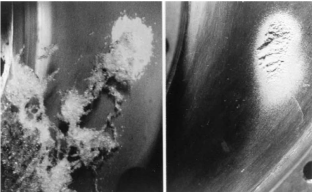

Therefore, when complete the pump is back to its original performance specifications and has a new 1-year warranty from SPX Flow. Due to the new oversized body, standard rotors are not used due to potential damage or failure of the pump. Also a pump can be remanufactured two times in its lifetime. Therefore cost of a remanufactured pump is approximately 75% of the cost of a new pump. microscopic in size, but the cumulative effect of millions of pits over a period of time can destroy a pump impeller. Cavitation can also cause excessive pump vibration which damages bearings, wearing rings and seals.

microscopic in size, but the cumulative effect of millions of pits over a period of time can destroy a pump impeller. Cavitation can also cause excessive pump vibration which damages bearings, wearing rings and seals.

After one month, the customer loves the new process improvements. They are maintaining a more consistent flow rate of 80-110 gpm and lower pressures of 60 psi. Production increased by 26% with more consistent product and a quieter production area. Maintenance and downtime decreased by 30%.

After one month, the customer loves the new process improvements. They are maintaining a more consistent flow rate of 80-110 gpm and lower pressures of 60 psi. Production increased by 26% with more consistent product and a quieter production area. Maintenance and downtime decreased by 30%.

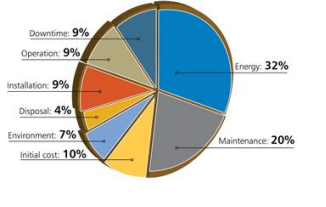

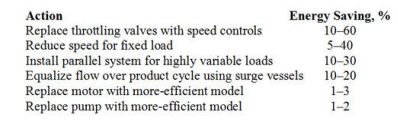

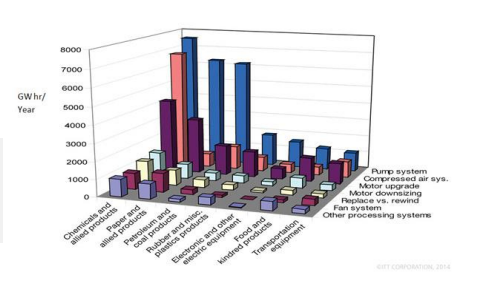

Most chemical plants are working to become more energy efficient. Companies are implementing energy management software, installing occupancy sensors throughout plants to help lower electricity bills, and even changing times of operation to use less power at peak load to avoid the associated higher rates. One of the best ways to save energy is to focus on motor-driven pumps.

Most chemical plants are working to become more energy efficient. Companies are implementing energy management software, installing occupancy sensors throughout plants to help lower electricity bills, and even changing times of operation to use less power at peak load to avoid the associated higher rates. One of the best ways to save energy is to focus on motor-driven pumps.