Major Impact

- Does not require disconnection and invasive inspection.

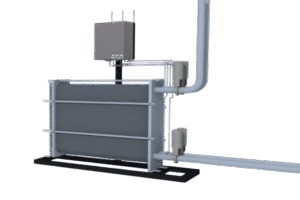

- Able to be installed retrospectively to existing lines with different types of heat exchangers or tanks.

- Utilizes process water, resulting in no contamination or post-test cleaning.

- Qualification of leaks.

Medium Impact

- On demand testing carried out on an automated or manual process at start of each shift or batch.

- Tests are carried out in-situ and under operational conditions without requiring a high-pressure differential.

- Data available in real time remotely or at the module.

- Automated operation with no advanced training required.

Additional Impact

- Significantly shorter and reliable testing eliminating downtime.

- Mitigates false readings due to liquid test media.

- More accurate pressure testing tolerance.

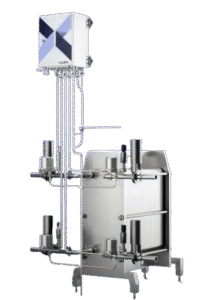

ExiFlo is an innovative retrofit hardware device which monitors and tests the integrity of any close liquid or gas system in service within heat exchange systems. ExiFlo is able to identify leaks across the boundaries and into the outside environment without the need to take the system off-line. Furthermore, these tests are quickly carried out before and after each production cycle, to ensure that each product batch receives a pass or fail certification before leaving for distribution.

ExiFlo minimises risk of contamination from cross-channel flow, which can lead to unplanned and costly downtime, reduction in efficiency, contamination of utility systems and product recalls that are highly damaging to brand reputation. In this manner, ExiFlo maximises your brand’s compliance.

Click to Watch A Video for More Information

For more information, visit our website: www.mgnewell.com and www.newellautomation.com.