Load Cells 101

Weights play a significant role in our lives, more than we might realize. Knowing the weight of a particular substance is the most accurate measurement for private and industrial spheres alike. For example, we use weights to price food at the grocery’s self-checkout line or know how healthy we are at home. Weights also indicate precise measurements for ingredients, agricultural products, medical products, and much more. How do we know what things weigh? Load cells save the day.

WHAT IS A LOAD CELL?

A load cell is not a scale or a balance, but a transducer or sensor, which measures mechanical force and converts the energy of a force into a digital or analog measurable output. The force applied to the load is proportional to the strength of the output. A load cell can use different methods to translate force into a weight measurement. This paper will cover designs according to the type of output signal generated – hydraulic, pneumatic and strain gauge. The most common load cell used in industrial weighing are strain gauge load cells.

mechanical force and converts the energy of a force into a digital or analog measurable output. The force applied to the load is proportional to the strength of the output. A load cell can use different methods to translate force into a weight measurement. This paper will cover designs according to the type of output signal generated – hydraulic, pneumatic and strain gauge. The most common load cell used in industrial weighing are strain gauge load cells.

TYPES OF LOAD CELLS

Hydraulic:

The word hydraulic should let us know that this sensor will work by using fluid, whether water or oil. A hydraulic load cell uses water or a liquid to measure the mechanical force of an object. A change in the pressure in the internal liquid translates into weight.

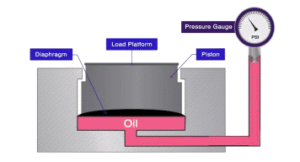

Hydraulic load cells consist of:

– An elastic diaphragm

– A piston with a loading platform on top of the diaphragm

– Oil or water that will be inside the piston

– A bourdon tube pressure gauge

When a load is placed on the loading platform the piston applies pressure to the liquid contained inside it. The pressure increase of the liquid is proportional to the applied force or weight. After calibrating the pressure, you can accurately measure the force or weight applied to the hydraulic load cell. The pressure reading can be read as an analog gauge or it can be converted into an electric signal from a pressure sensor. If the load cells have been properly installed and calibrated, accuracy can be within 0.25% full scale or better, acceptable for most process weighing applications. Because this sensor has no electric components, it is ideal for use in hazardous

areas. Typical hydraulic load cell applications include tank, bin, and hopper weighing. For maximum accuracy, the weight of the tank should be obtained by locating one force sensor at each point of support and summing their outputs.

Pneumatic:

Since it is pneumatic, we know that it will deal with air pressure. A pneumatic load cell consists of an elastic diaphragm which is attached to a platform surface where the weight will be measured. There will be an air regulator that will limit the flow of air pressure to the system and a pressure gauge. Thus, when an object is placed on a pneumatic load cell, it uses pressurized air or gas to balance out the weight of the object. The air required to balance out the weight will determine how heavy the object weights. The pressure gauge can convert the air pressure reading into an electrical signal. They take relatively small weights and have multiple sensors for greater accuracy. Pneumatic load cells use multiple dampener chambers to provide higher accuracy than can a hydraulic device. In some designs, the first dampener chamber is used as a tare weight chamber. Pneumatic load cells are often used to measure relatively small weights in industries where cleanliness and safety are of prime concern. The advantages of this type of load cell include their being inherently explosion proof and insensitive to temperature variations. Additionally, they contain no fluids that might contaminate the process if the diaphragm ruptures. Disadvantages include relatively slow speed of response and the need for clean, dry, regulated air or nitrogen.

heavy the object weights. The pressure gauge can convert the air pressure reading into an electrical signal. They take relatively small weights and have multiple sensors for greater accuracy. Pneumatic load cells use multiple dampener chambers to provide higher accuracy than can a hydraulic device. In some designs, the first dampener chamber is used as a tare weight chamber. Pneumatic load cells are often used to measure relatively small weights in industries where cleanliness and safety are of prime concern. The advantages of this type of load cell include their being inherently explosion proof and insensitive to temperature variations. Additionally, they contain no fluids that might contaminate the process if the diaphragm ruptures. Disadvantages include relatively slow speed of response and the need for clean, dry, regulated air or nitrogen.

Strain Gauge:

A strain gauge load cell is a transducer that changes in electrical resistance when under stress or strain. The electrical resistance is proportional to the stress or strain placed on the cell making it easy to calibrate into an accurate measurement. The electrical resistance from the strain gauge is linear therefore it can be converted into a force and then a weight if needed. A strain gauge load cell is made up of 4 strain gauges in a “Wheatstone” bridge configuration. A Wheatstone bridge is an electrical circuit that measures unknown electrical resistance by balancing two legs of a bridge circuit, one of the legs contains the unknown component. The “Wheatstone bridge” circuit provides incredibly accurate measurements. The strain gauges that are in the Wheatstone bridge are bonded onto a beam which deforms when weight is applied.

under stress or strain. The electrical resistance is proportional to the stress or strain placed on the cell making it easy to calibrate into an accurate measurement. The electrical resistance from the strain gauge is linear therefore it can be converted into a force and then a weight if needed. A strain gauge load cell is made up of 4 strain gauges in a “Wheatstone” bridge configuration. A Wheatstone bridge is an electrical circuit that measures unknown electrical resistance by balancing two legs of a bridge circuit, one of the legs contains the unknown component. The “Wheatstone bridge” circuit provides incredibly accurate measurements. The strain gauges that are in the Wheatstone bridge are bonded onto a beam which deforms when weight is applied.

How to Choose a Load Cell for Your Application Determining which load cell your application requires depends on how sensitive and accurate your application needs to be. A strain gauge type of load cell would be first in line when it comes to accuracy and sensitivity. While still useful in certain applications, pneumatic and hydraulic load cells would be the less sensitive and accurate types.

Determining which load cell your application requires depends on how sensitive and accurate your application needs to be. A strain gauge type of load cell would be first in line when it comes to accuracy and sensitivity. While still useful in certain applications, pneumatic and hydraulic load cells would be the less sensitive and accurate types.