Pump Pressure Issues – Case Study

Inconsistent product output? Breaking pipe hangers and ferrules?

These system hammer issues can often be traced back to pump and pressure issues.

A producer of ingredients for human food and animal nutrition was having major issues in their process. They were inducting powdered maltodextrin into their process to form a starch slurry. During the maltodextrin induction process, air was getting into their PD pump. It was then pulled into a centrifugal booster pump that was pushing the slurry vertical 40 feet into a tank. They were experiencing low flow rates (30-60 gpm) and high pressures (>120 psi).

The product was building up in the pump housing seals. Product output was inconsistent. They were breaking ferrules and hangars. They had long periods of downtime. Operators were trying to overspeed the motors on the pumps to increase production rates.

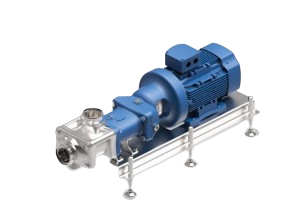

The M.G. Newell salesman recommended that the customer consider a twin-screw pump. Twin-screw pumps can handle highly viscous products such as starch slurries. The design minimizes shearing in the product while still handling high pressures and higher speeds. Most importantly, the pump can handle any air that may be pushed into the line from the powder induction system. The customer removed the PD pump and the centrifugal booster pump and replaced them with 2 twin-screw pumps. They also switched 2” tubing and ball valves to 3” tubing and added an overpressure valve after the first pump.

After one month, the customer loves the new process improvements. They are maintaining a more consistent flow rate of 80-110 gpm and lower pressures of 60 psi. Production increased by 26% with more consistent product and a quieter production area. Maintenance and downtime decreased by 30%.

After one month, the customer loves the new process improvements. They are maintaining a more consistent flow rate of 80-110 gpm and lower pressures of 60 psi. Production increased by 26% with more consistent product and a quieter production area. Maintenance and downtime decreased by 30%.

If you are frustrated with extended maintenance and downtimes, give us a call. We are happy to share our experience with you. Contact one of our associates to see how We Make It Work Better.