Pump Repair Training – Case Study

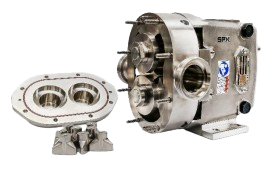

A customer was having a difficult time with positive displacement pumps needing frequent and costly repairs. After discussions with the plant engineer and sanitation, we felt we had a good grasp on the cause of the problem.

That is where Pump Repair Training comes in.

The plant had experienced a change in personnel over the last 3 – 6 months on both the sanitation and maintenance staff. Some of the basic steps in disassembly and reassembly had not been properly performed along with missing preventive maintenance steps. The pumps were able to perform, but damage was occurring causing inefficiencies and expense in the upkeep.

missing preventive maintenance steps. The pumps were able to perform, but damage was occurring causing inefficiencies and expense in the upkeep.

Preventative Maintenance

We review our findings with the plant engineer. We don’t suggest a new pump. Instead, we determine that a “refresher” training course is needed to make sure everyone knew the proper sequence of assembly and proper preventive maintenance requirements of positive displacement pumps.

The hands-on pump repair training, proves to be the key in getting the process to turn around and reduce the occurrence of breakdown. This has led to lower maintenance cost and more production operating time. We sometimes lose sight of the “basic” practices that keep our operations functioning smoothly. It is very important that routine training programs and PM plans are in place to review equipment procedures that keep your process running smooth, safe, and cost effective.

The hands-on pump repair training, proves to be the key in getting the process to turn around and reduce the occurrence of breakdown. This has led to lower maintenance cost and more production operating time. We sometimes lose sight of the “basic” practices that keep our operations functioning smoothly. It is very important that routine training programs and PM plans are in place to review equipment procedures that keep your process running smooth, safe, and cost effective.

M.G. Newell and our equipment manufacturers offer plant audits that help assist you in maintaining your equipment and provide training and preventative maintenance programs. We realize in this “challenged” economy that everyone is looking for ways to tighten their process parameters and keep costs down. This is just another way that M.G. Newell makes it work better.