100% Sealed Flexible Connectors

M.G. Newell is proud to be a key partner with BFM® Fitting. We have extensive experience with their products and offer full engineering and technical support to make sure you get the right product for your application.

BFM fitting is the connector of choice for global manufacturers in the food, chemical, pharmaceutical and mineral industries. From metal detectors to sifters, high pressure or vacuum, BFM fitting connectors are used in a wide range of industrial applications.

Years of expertise and industry knowledge have created a transformed flexible connector.

Benefits of BFM Connectors vs Traditional Hose Clamps

Traditional: Hose Clamp Fabric Sleeve

- Multiple sizes, materials, fitting types & safety conformity make stock monitoring complex. Inconsistent sizes and fit when installing manually cut sleeve materials.

- Valuable product can be lost due to constant connector leakage. Clamped connectors prone to tearing leading to product spillage.

- Slow and difficult to change. Longer plant downtime during CIP & maintenance. Connectors wear out faster.

- Overpressure causes hose clamp failure before connector failure.

- Tools can damage connectors. Installer’s hands at risk.

- Inaccurate measurements & product variations create ill-fitting connections. Installation problems due to variation in fabrication.

- Powder leaks through hose clips. Build up between spigot and connector.

Transformed: BFM Integrated System

- Streamlines inventory control and improves supply chain sustainability. Standardized exact sizes ensures perfect fit every time.

- 100% seal prevents product leakage. Superior material strength and snap-fit design means connectors won’t tear.

- Fastest change over in industry guarantees minimal machine interruption. More durable connector means less change overs.

- Seals tighter under pressure. Independently explosion tested to 60 kPa +

- Tool free snap fit. Hand safe assembly. Clean & transparent connector gives

product flow visibility.

- Perfect fit every time – only in the

correct place.

- Leak free – Dust free No crevices to collect product.

The BFM Fitting system comprises two spigots (or flanges) that are welded to your pipes, and a snap-fit flexible connector that seats on the inside of the shaped portion of the two spigots, holding it securely in place; The stainless steel spigots have a tail 52mm long. These can be easily cut down or cut on an angle to suit your existing pipework.

BFM’s flexible connectors are available in a wide range of diameters and lengths. Pipe and spigot length can be adjusted to ensure the optimum fit within an appropriate Installation Gap (IG) for the connector length (CL).

The Installation Gap is always slightly smaller than the actual connector length to allow for ease of connector replacement and any offset or movement during operation.

BFM Fitting Product Range

BFM Fitting Products

NON-PERMEABLE CONNECTORS

SEEFLEX 040E – STRONG, MOST RESILIENT MULTI-PURPOSE CONNECTOR

• Temp. Range: -25°C to 110°C (-13°F to 230°F) • Surge Temp: 120°C (248°F)

• Surface Resistivity: 1010 Ω (Tested to ASTM D-257)

• Atex Compliant: IBExU tested

• Regulations: FDA 21 CFR 177.1680 & 177.2600, USDA & 3A (20-), (EC) 1935/2004, 2023/2006 & 10/2011

SEEFLEX 020E – LIGHTWEIGHT & FLEXIBLE, IDEAL FOR WEIGHSCALE APPLICATIONS

• Temp Range: -25°C to 80°C (13°F to 176°F) • Surge Temp: 100°C (212°F)

• Surface Resistivity: 1010 Ω (Tested to ASTM D-257)

• Atex Compliant: IBExU tested

• Regulations: FDA 21 CFR 177.1680 & 177.2600, USDA & 3A (20-), (EC) 1935/2004, 2023/2006 & 10/2011

SEEFLEX 040AS – DESIGNED TO DISSIPATE STATIC, IDEAL FOR POTENTIALLY EXPLOSIVE AREAS

• Temp. Range: -25°C to 95°C (-13°F to 203°F) • Surge Temp: 100°C (212°F)

• Surface Resistivity: 108 Ω (very good at dissipating static – Tested to ASTM D-257)

• Clear ether-based polyurethane with antistatic infusion

• Regulations: FDA 21 CFR 177.1680 & 177.2600, USDA & 3A (20-), (EC) 1935/2004, 2023/2006 & 10/2011

SEEFLEX 060ES – SUPERIOR STRENGTH FOR OVER-PRESSURE SITUATIONS

• Temp. Range: -25°C to 120°C (-13°F to 248°F) • Ether based polyurethane with internally bonded polyester scrim

• Surface Resistivity: 1010 Ω (Tested to ASTM D-257)

• Used for continuous pressure situations up to 1.3 bar

• Regulations: FDA 21 CFR 177.1680 & 177.2600, USDA & 3A (20-), (EC) 1935/2004, 2023/2006 & 10/2011

FLEXI – SEEFLEX + WIRE COIL – IDEAL FOR BAG FEEDERS & FILLING HEADS

• Temp Range: -20°C to 85°C (-4°F to 185°F) • Approx compression ratio: 3:1

• Also available as Flexi-Light (more flexible coil) and Flexi-Earthed with terminal lugs attached to coil ends

• Regulations: FDA 21 CFR 177.1680, 175.105 (adhesives) & 177.2600, USDA & 3A (20-), (EC) 1935/2004,

2023/2006 & 10/2011

TEFLEX NP BLACK (NON-PERMEABLE) – PTFE LAMINATE FOR TEMPERATURE EXTREMES & CHEMICALS

• Temp Range: -73°C to 300°C (-99°F to 572°F) • Surge Temp: 316°C (600°F)

• Teflex NP can be used on products across the full pH scale (caustic/acid products will not effect Teflex NP)

• Designed to dissipate electrical charge – Surface Resistivity: 106 Ω

• Regulations: FDA 21 CFR 177.1550, 175.105 & 178.3297, (EC) 1935/2004, 2023/2006 & 10/2011

BLANKING CAPS – AS SIGHT-GLASSES/VIEWING PORTS & SEALING DURING CHANGEOVERS

• Used to prevent contamination during clean down or change-over, also as sight-glasses/inspection ports

• Available in: Ø100mm (4”), Ø125mm (5”), then Ø150mm (6”) to Ø1,650mm (65”) in 50mm (2”) increments

• All blanking caps are 30mm (1 3/16”) in length

• Manufactured from Seeflex 040E (so same material/operational specs & compliance applies)

WOVEN CONNECTORS

LM3 – 100% WOVEN POLYPROPYLENE – BREATHABLE & SUITABLE FOR LOW TEMPERATURES

• Temp. Range: -70°C to 94°C (-94°F to 201°F) • Surge Temp: 107°C (225°F)

• Air Permeability: 13 (cm3/cm2/sec@125Pa) 25 (ft3/ft2/min@0.5” wg)

• Regulations: FDA 21 CFR 177.2800, (EC) 1935/2004, 2023/2006 & 10/2011

LM4 – 100% WOVEN POLYESTER – SUITABLE FOR HIGHER TEMPERATURES

• Maximum Operating Temp: 130°C (266°F) continuous

• Surge Temp: 150°C (302°F)

• Air Permeability: 0.4 (cm3/cm2/sec@125Pa) 0.8 (ft3/ft2/min@0.5” wg)

• Regulations: FDA 21 CFR 177.2800, (EC) 1935/2004, 2023/2006 & 10/2011

TEFLEX WOVEN – PURE WOVEN PTFE – HIGH TEMPERATURE & CHEMICAL RESISTANT

• Maximum Operating Temp: 260°C (500°F) • Surge Temp: 280°C (536°F)

• Air Permeability: 0.3 (cm3/cm2/sec@125Pa) 0.5 (ft3/ft2/min@0.5” wg)

• Teflex can be used on products across the full PH scale (either caustic or acid)

• Regulations: FDA 21 CFR 177.1550, 178.3297

MORE BFM FITTING PRODUCTS

BULK BAG LOADER – INFLATABLE LOADING HEAD FOR HYGIENIC OPERATION

- Inflates in seconds and seals tight on the neck of the bulk bag, eliminating products leaks.

- Much safer for workers hands as there are no pinch points.

- Can be used on bulk bags with or without plastic liners.

RINGS OPTION – SUPPORT / ANTI-COLLAPSE RINGS TO KEEP CONNECTOR WALLS OPEN

- Ideal for use under negative pressure or for longer length connectors or compression applications.

- Available in stainless steel to Ø500mm(20″) or plastic to Ø1,000mm (39 1/2″))

- Can be added Seeflex 040E (incl Wash Sleeves), Seeflex 040AS, LM3, LM4, Teflex and Teflex NP only.

- Multiple rings can be inserted up to 10 in total, subject to minimum spacing (Teflex NP maximum is 8).

TOOL RELEASE (TR) OPTION – FOR ADDED SAFETY LAYER OR HIGH VACUUM APPLICATIONS.

- Connectors have much firmer ‘snap-bands’ to make virtually impossible to release manually.

- Specialist rounded-end BFM Tool Release Tool used to release connector through hole in spigot.

- Any BFM fitting connector can be supplied as a TR option (with the firmer bands).

- Additional safety level offered with uniquely shaped ‘Smiley Face’ TR Tool option.

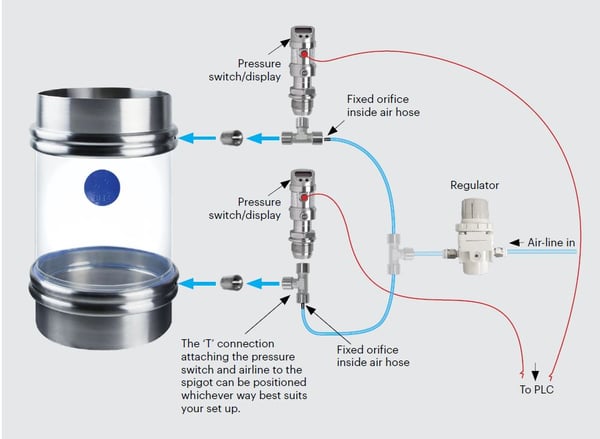

The system works by pumping pressurised air

between the silicone cuff of the BFM® connector

and the spigot.

Air line sensors immediately detect if this outward

pressure is released as the connector cuff begins

to get pushed inwards anywhere around the

connector when it is being removed, setting off an

alarm and/or shutting off any moving parts below.

The system has a tamper-proof gauge, and can

also be used as a positional sensor to ensure all

connectors in a large plant are installed correctly at

all times.

For more information, visit our website: www.mgnewell.com and www.newellautomation.com.