Calibration Principles

Calibration is the activity of checking, by comparison with a standard, the accuracy of a measuring instrument of any type. It may also include adjustment of the instrument to bring it into alignment with the standard. Even the most precise measurement instrument is of no use if you cannot be sure that it is reading accurately – or, more realistically, that you know what the error of measurement is. Let’s begin with a few definitions:

Calibration range – the region between the within which a quantity is measured, received or transmitted which

is expressed by stating the lower and upper range values.

Zero value – the lower end of the calibration range

Span – the difference between the upper and lower range

Instrument range – the capability of the instrument; may be different than the calibration range

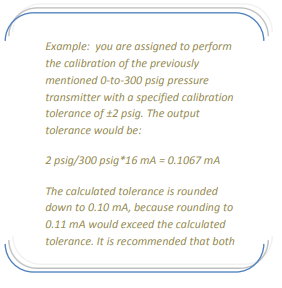

For example, an electronic pressure transmitter may have an instrument range of 0–750 psig and output of 4-to-20 milliamps (mA). However, the engineer has determined the instrument will be calibrated for 0-to-300 psig = 4-to-20 mA. Therefore, the calibration range would be specified as 0-to-300 psig = 4-to-20 mA. In this example, the zero input value is 0 psig and zero output value is 4 mA. The input span is 300 psig and the output span is 16 mA.

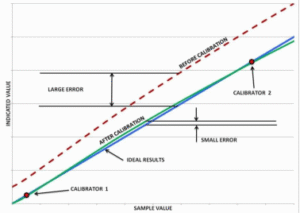

Ideally a product would produce test results that exactly match the sample value, with no error at any point within the calibrated range. This line has been labeled “Ideal Results”. However, without calibration, an actual product may produce test results different from the sample value, with a potentially large error. Calibrating the product can improve this situation significantly. During calibration, the product is “taught” using the known values of Calibrators 1 and 2 what result it should provide. The process eliminates the errors at these two points, in effect moving the “Before Calibration” curve closer to the Ideal Results line shown by the “After Calibration” curve. The error has been reduced to zero at the calibration points, and the residual error at any other point within the

“Ideal Results”. However, without calibration, an actual product may produce test results different from the sample value, with a potentially large error. Calibrating the product can improve this situation significantly. During calibration, the product is “taught” using the known values of Calibrators 1 and 2 what result it should provide. The process eliminates the errors at these two points, in effect moving the “Before Calibration” curve closer to the Ideal Results line shown by the “After Calibration” curve. The error has been reduced to zero at the calibration points, and the residual error at any other point within the

operating range is within the manufacturer’s published linearity or accuracy specification.

Every calibration should be performed to a specified tolerance. The terms tolerance and accuracy are often used incorrectly. In ISA’s The Automation, Systems, and Instrumentation Dictionary, the definitions for each are as follows:

Accuracy – the ratio of the error to the full scale output or the ratio of the error to the output, expressed in percent span or percent reading, respectively.

Tolerance – permissible deviation from a specified value; may be expressed in measurement units, percent of span, or percent of reading.

It is recommended that the tolerance, specified in measurement units, is used for the calibration requirements performed at your facility. By specifying an actual value, mistakes caused by calculating percentages of span or reading are eliminated. Also, tolerances should be specified in the units measured for the calibration. Calibration tolerances should be determined from a combination of factors.

These factors include:

• Requirements of the process

• Capability of available test equipment

• Consistency with similar instruments at your facility

• Manufacturer’s specified tolerance

The term Accuracy Ratio was used in the past to describe the relationship between the accuracy of the test standard and the accuracy of the instrument under test. A good rule of thumb is to ensure an accuracy ratio of 4:1 when performing calibrations. This means the instrument or standard used should be four times more accurate than the instrument being checked. In other words, the test equipment (such as a field standard) used to calibrate the process instrument should be four times more accurate than the process instrument. With today’s technology, an accuracy ratio of 4:1 is becoming more difficult to achieve. Why is a 4:1 ratio recommended? Ensuring a 4:1 ratio will minimize the effect of the accuracy of the standard on the overall calibration accuracy. If a higher level standard is found to be out of tolerance by a factor of two, for example, the calibrations performed using that standard are less likely to be compromised. The out-of-tolerance standard still needs to be investigated by reverse traceability of all calibrations performed using the test standard. However, our assurance is high that the process instrument is within tolerance.

Traceability

Last but not least, all calibrations should be performed traceable to a nationally or internationally recognized standard. For example, in the United States, the National Institute of Standards and Technology (NIST) maintains the nationally recognized standards. Traceability is defined by ANSI/NCSL Z540-1-1994 as “the property of a result of a measurement whereby it can be related to appropriate standards, generally national or international standards, through an unbroken chain of comparisons.” Note this does not mean a calibration shop needs to have its standards calibrated with a primary standard. It means that the calibrations performed are traceable to NIST through all the standards used to calibrate the

standards, no matter how many levels exist between the shop and NIST. Traceability is accomplished by ensuring the test standards we use are routinely calibrated by “higher level” reference standards. Typically the standards we use from the shop are sent out periodically to a standards lab which has more accurate test equipment. The standards from the calibration lab are periodically checked for calibration by “higher level” standards, and so on until eventually the standards are tested against Primary Standards maintained by NIST or another internationally recognized standard.

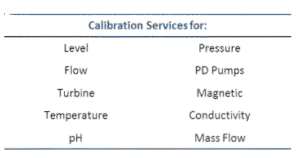

The calibration technician’s role in maintaining traceability is to ensure the test standard is within its calibration interval and the unique identifier is recorded on the applicable calibration data sheet when the instrument calibration is performed. Additionally, when test standards are calibrated, the calibration documentation must bereviewed for accuracy and to ensure it was performed using NIST traceable equipment. M.G. Newell offers a variety of calibration services that keep your operations consistent and cost effective. Contact your local account manager for rates and plan options.

standard is within its calibration interval and the unique identifier is recorded on the applicable calibration data sheet when the instrument calibration is performed. Additionally, when test standards are calibrated, the calibration documentation must bereviewed for accuracy and to ensure it was performed using NIST traceable equipment. M.G. Newell offers a variety of calibration services that keep your operations consistent and cost effective. Contact your local account manager for rates and plan options.

utilized for pieces of equipment and utensils that cannot be cleaned where they are used and must be disassembled, and for pieces of equipment that are complex and hard to clean. With a greater emphasis on sanitary design in food plants, equipment manufacturers and industry have worked together to make many improvements to equipment and parts that make cleaning and sanitizing more effective. Even so, plant sanitation crews and quality assurance/quality control (QA/QC) managers cannot rely solely on the fact that equipment is more cleanable today than in the past. Introducing or improving CIP and COP procedures, processes and systems in the food plant takes advantage of sanitary equipment design benefits, raising the level of assurance that when the production line starts up for a new run the process is in control from the get-go. With this in mind, here are a few tips to best-practice approaches in using CIP and COP systems to their fullest potential as process control measures.

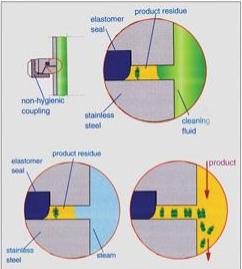

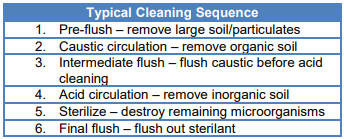

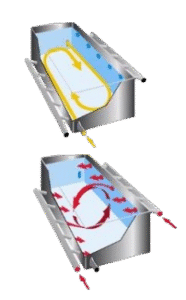

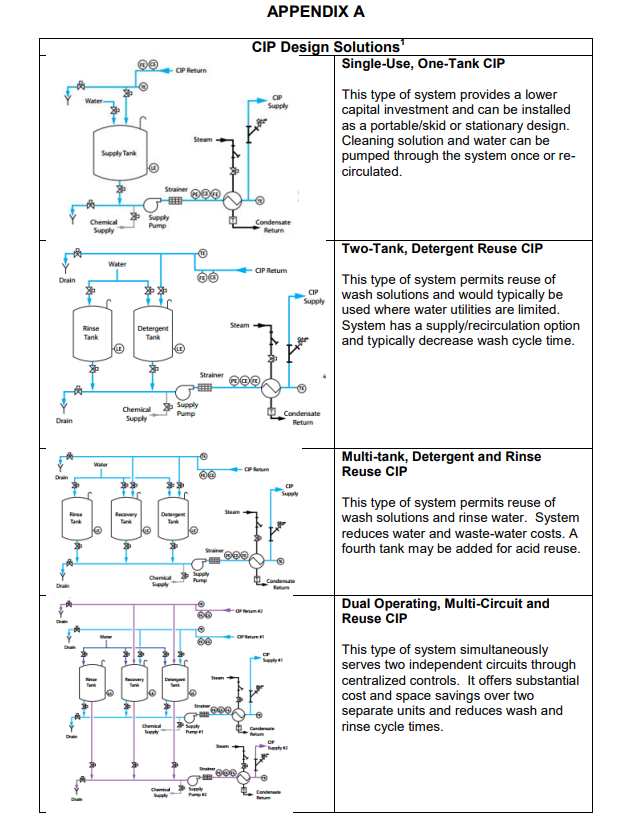

utilized for pieces of equipment and utensils that cannot be cleaned where they are used and must be disassembled, and for pieces of equipment that are complex and hard to clean. With a greater emphasis on sanitary design in food plants, equipment manufacturers and industry have worked together to make many improvements to equipment and parts that make cleaning and sanitizing more effective. Even so, plant sanitation crews and quality assurance/quality control (QA/QC) managers cannot rely solely on the fact that equipment is more cleanable today than in the past. Introducing or improving CIP and COP procedures, processes and systems in the food plant takes advantage of sanitary equipment design benefits, raising the level of assurance that when the production line starts up for a new run the process is in control from the get-go. With this in mind, here are a few tips to best-practice approaches in using CIP and COP systems to their fullest potential as process control measures. removed. It is important that tanks are properly vented, are self-draining and that the floor of the vessel allows for fast flushing. Figure 1 aptly illustrates the the contamination that can occur when equipment components such as coupling is not of sanitary design. If the only treatment materials that will be used in or flow through the system during CIP are rinse water and cleaning solution, a two-tank system will likely be adequate. If your process requires an additional function, such as an acid wash or retention of final rinse water, a three-tank or return pump system is warranted. Since CIP systems vary in application and sophistication, check with CIP equipment manufacturers to ensure that a system is right for your operation. Also make sure that there are a sufficient number of tanks for the cleaning solutions used and that they can contain sufficient quantity, about 50 percent more solution, than required to avoid running out of solution. Similarly, check that the spray balls used to deliver the cleaning agents to the interior surfaces of the equipment are actually appropriate for the tanks in which they are employed. Spray balls are designed to work within specified conditions and parameters involving flow rate, pressure and shape of the tank(s) in the circuit. If the spray balls are tampered with, damaged or not maintained in good condition, the distribution of the cleaning and sanitizing chemicals will be ineffective.

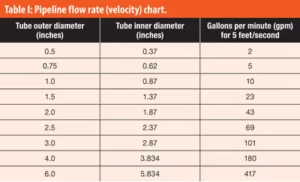

removed. It is important that tanks are properly vented, are self-draining and that the floor of the vessel allows for fast flushing. Figure 1 aptly illustrates the the contamination that can occur when equipment components such as coupling is not of sanitary design. If the only treatment materials that will be used in or flow through the system during CIP are rinse water and cleaning solution, a two-tank system will likely be adequate. If your process requires an additional function, such as an acid wash or retention of final rinse water, a three-tank or return pump system is warranted. Since CIP systems vary in application and sophistication, check with CIP equipment manufacturers to ensure that a system is right for your operation. Also make sure that there are a sufficient number of tanks for the cleaning solutions used and that they can contain sufficient quantity, about 50 percent more solution, than required to avoid running out of solution. Similarly, check that the spray balls used to deliver the cleaning agents to the interior surfaces of the equipment are actually appropriate for the tanks in which they are employed. Spray balls are designed to work within specified conditions and parameters involving flow rate, pressure and shape of the tank(s) in the circuit. If the spray balls are tampered with, damaged or not maintained in good condition, the distribution of the cleaning and sanitizing chemicals will be ineffective. essentially “scrubbed.” This means the flow must be greater than 5 ft. per second. To achieve this flow rate, operators need to understand their specific processing system. To do this, make sure that pump sizes are sufficient for the size of the tank or length of pipes to be cleaned. The rule of thumb is that the pump can produce a flow rate four to five times the rate of the product flow. For example, turbulent flow may be achieved in a one-inch pipe at a flow rate of 24 gallons per minute (gpm), whereas a four-inch pipe requires a flow rate of 180 gpm. The same holds true for tanks, ovens or other large vessels. To calculate proper flow in a tank, take the circumference in feet times two. This will give the user a minimum flow in gpm needed to clean the tank and sufficient volumes of cleaner flowing down the sides of the tank for turbulent flow.

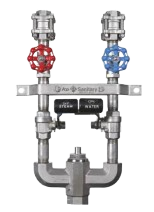

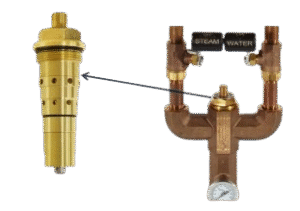

essentially “scrubbed.” This means the flow must be greater than 5 ft. per second. To achieve this flow rate, operators need to understand their specific processing system. To do this, make sure that pump sizes are sufficient for the size of the tank or length of pipes to be cleaned. The rule of thumb is that the pump can produce a flow rate four to five times the rate of the product flow. For example, turbulent flow may be achieved in a one-inch pipe at a flow rate of 24 gallons per minute (gpm), whereas a four-inch pipe requires a flow rate of 180 gpm. The same holds true for tanks, ovens or other large vessels. To calculate proper flow in a tank, take the circumference in feet times two. This will give the user a minimum flow in gpm needed to clean the tank and sufficient volumes of cleaner flowing down the sides of the tank for turbulent flow. steam would bore out the inner working components in the washdown system. Safety had become an issue. The needle valves, once bored out, would not fall back into the saddle correctly. Once that occurred, a steam backdraft was created which would come out of the spray nozzle. These bursts of steam and extremely hot water were a huge safety risk for their associates. Casey O’Rear, our account manager in GA, listened to their concerns and decided to present the Ace Sanitary Silent Type Venturi Mixer (STVM) wash down station to the Safety Manager. The STVM uses a venturi mixing valve that combines steam and water for a constant stream at the operator’s set temperature. He brought in a sample that showed how easy it is to remove and replace the patented venturi cartridge and illustrated the safety shutoff feature if the water exceeds the factory set temp.

steam would bore out the inner working components in the washdown system. Safety had become an issue. The needle valves, once bored out, would not fall back into the saddle correctly. Once that occurred, a steam backdraft was created which would come out of the spray nozzle. These bursts of steam and extremely hot water were a huge safety risk for their associates. Casey O’Rear, our account manager in GA, listened to their concerns and decided to present the Ace Sanitary Silent Type Venturi Mixer (STVM) wash down station to the Safety Manager. The STVM uses a venturi mixing valve that combines steam and water for a constant stream at the operator’s set temperature. He brought in a sample that showed how easy it is to remove and replace the patented venturi cartridge and illustrated the safety shutoff feature if the water exceeds the factory set temp.  The Safety Manager was very impressed with the safety features inherent in the STVM washdown station. As an added bonus, he was also impressed with the ease of cleaning and switching out the cartridge. The existing washdown system had over 36 internal parts to replace. The STVM system has one cartridge to replace and change out only takes a wrench and a few minutes. The customer only needs

The Safety Manager was very impressed with the safety features inherent in the STVM washdown station. As an added bonus, he was also impressed with the ease of cleaning and switching out the cartridge. The existing washdown system had over 36 internal parts to replace. The STVM system has one cartridge to replace and change out only takes a wrench and a few minutes. The customer only needs  Manufacturing processes using bioreactors and fermenters require a well-thought-out plan to achieve a valid clean. A key consideration during the planning stage is how to successfully integrate an automated system for cleaning processing equipment in place without disassembly, also known as cleaning-in-place (CIP). Designing and sizing a CIP system for sufficient flow and pressure The flow and pressure required to CIP a manufacturing process, such as a bioreactor or fermenter, is dictated by the vessel spray devices and process lines. Static spray balls are the most common spray device used; however, some processes may use rotating impingement spray devices for heavier soil loads. Most standard bioreactor and fermenter designs include a spray device and piping connection package with recommended CIP supply flow rate and pressure requirements. Custom applications require an evaluation to determine spray device and piping design.

Manufacturing processes using bioreactors and fermenters require a well-thought-out plan to achieve a valid clean. A key consideration during the planning stage is how to successfully integrate an automated system for cleaning processing equipment in place without disassembly, also known as cleaning-in-place (CIP). Designing and sizing a CIP system for sufficient flow and pressure The flow and pressure required to CIP a manufacturing process, such as a bioreactor or fermenter, is dictated by the vessel spray devices and process lines. Static spray balls are the most common spray device used; however, some processes may use rotating impingement spray devices for heavier soil loads. Most standard bioreactor and fermenter designs include a spray device and piping connection package with recommended CIP supply flow rate and pressure requirements. Custom applications require an evaluation to determine spray device and piping design.

COP systems are used to clean

COP systems are used to clean

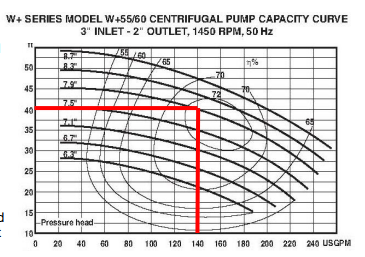

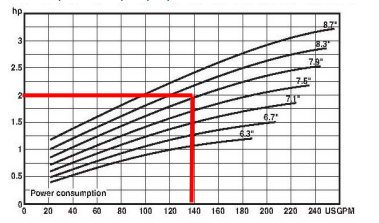

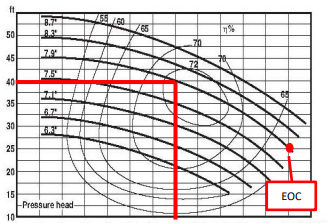

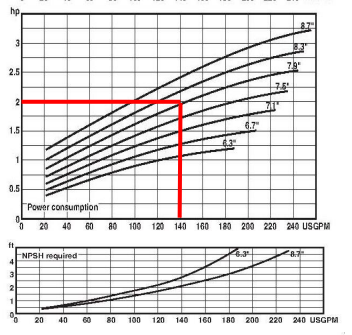

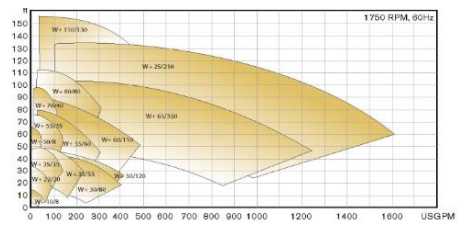

for various impeller diameters. In the example below, the impeller

for various impeller diameters. In the example below, the impeller

be considered to make sure that the motor is the correct size. The motor is typically sized not at the peak efficiency point but by the maximum power draw that will be needed. It is common practice to size the motor for the End of Curve (EOC) horsepower requirements. In the example shown, even though 2 hp is required for a flow of 140 gpm with 40 ft head, the end of curve horsepower requires a 2.5 hp motor be used.

be considered to make sure that the motor is the correct size. The motor is typically sized not at the peak efficiency point but by the maximum power draw that will be needed. It is common practice to size the motor for the End of Curve (EOC) horsepower requirements. In the example shown, even though 2 hp is required for a flow of 140 gpm with 40 ft head, the end of curve horsepower requires a 2.5 hp motor be used.  different flows.

different flows.

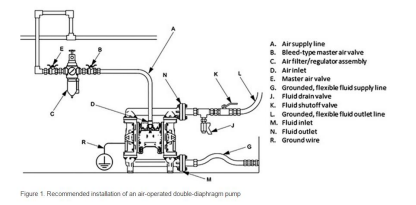

and outlet hose sizes match the size of the

and outlet hose sizes match the size of the