The Case of the Locking Rotors

When the Pumps Went Silent, the Pressure Told the Truth

Detective Newell hated getting calls before coffee. This one came from one of the outside saleswomen. “Newell,” she said, voice tight. “My customers got a problem. Ten U2-006 PD pumps that are all locked up.”

Locked up pumps were never just locked up pumps. They were always a symptom—never the disease. Newell grabbed his jacket and motioned to Inspector Gauge. “Let’s go see what the pumps are trying to tell us.”

They found the pumps mounted on their sides, perched above a piece of equipment installed by another contractor. Newell didn’t like that already. Pumps, like people, don’t appreciate being put in awkward positions.

They cracked them open one by one. Same story every time.

“Notice this?” Inspector Gauge said, pointing.

Newell nodded. “One side locks up first. Always the same side.”

Back at the shop, they tore down four of the suspects. The evidence didn’t lie: rotors had kissed the cover—hard—and seized. “Running dry,” Newell muttered. “Starved.”

They told the customer as much, but the customer pushed back. “No way. That’s not it. Let’s try hot clearance rotors.”

Newell didn’t argue. He’d learned long ago that sometimes people need to walk into the truth on their own.

Before the fixes even started, the phone rang again.

More pumps.

Locked up.

Same equipment.

All twenty U2-006 PD pumps were now suspects—and victims. Newell and Gauge went back to the plant. Déjà vu. Same damage. Same story.

“You’re running them dry,” Newell said again, slower this time. The customer still wasn’t convinced. So Newell made his move. “Then let us watch them run.”

They met with an engineer and walked the process line end to end. Newell asked questions. He listened. He watched. He always watched…

“How much pressure are you seeing?” he asked.

“About 8 PSI,” the engineer replied. Newell stopped walking. “8?” He looked at Gauge. Gauge didn’t have to say anything. “That’s not just low,” Newell said. “That’s a confession.”

He told them to install temporary pressure gauges. No theories. No opinions. Just facts.

They ran the system again. Three minutes in, Newell spotted it – the centrifugal pump feeding the PD pumps wasn’t running.

“There it is,” he said quietly. “That’s the culprit.”

Newell laid it out clean and simple. “The centrifugal pump must always run first. Always.” PD pumps can’t be started without feed pressure. If a PD pump runs dry, the rotors expand, touch the cover and lock up. An improper start sequence and low PSI in the feed lines will always lead to problems.

They changed the sequence. Ran the test again. The pumps didn’t lock – didn’t squeal – didn’t complain. They just ran.

Another mystery solved. Another reminder that the correct start-up sequence is never optional. Another case where the culprit wasn’t a broken part— but bad timing, low pressure, and the truth hiding in plain sight.

At first glance, something felt wrong. As the crate was opened, Detective Newell leaned in, scanning the evidence. No covers. No bodies. No rotors. Just gear cases—bare, incomplete, and unwilling to tell their story.

At first glance, something felt wrong. As the crate was opened, Detective Newell leaned in, scanning the evidence. No covers. No bodies. No rotors. Just gear cases—bare, incomplete, and unwilling to tell their story.

Serial numbers exist for a reason—components are machined to tight tolerances and tested as a set. Ignoring that fact may keep a pump running temporarily, but it significantly increases the risk of failure.

Serial numbers exist for a reason—components are machined to tight tolerances and tested as a set. Ignoring that fact may keep a pump running temporarily, but it significantly increases the risk of failure.

and CIP solution. As seen in the picture, their old submersible mixer and motors were struggling in this harsh environment. Therefore, Plant associates were servicing and often replacing the motors every few months. Our M.G. Newell sales associate recommended a motor from Stainless Motors, Inc (SMI). SMI is a US-based manufacturer of stainless-steel wash-down motors, gear reducers and

and CIP solution. As seen in the picture, their old submersible mixer and motors were struggling in this harsh environment. Therefore, Plant associates were servicing and often replacing the motors every few months. Our M.G. Newell sales associate recommended a motor from Stainless Motors, Inc (SMI). SMI is a US-based manufacturer of stainless-steel wash-down motors, gear reducers and  In our busy day to day operations, we sometimes lose sight of the time

In our busy day to day operations, we sometimes lose sight of the time

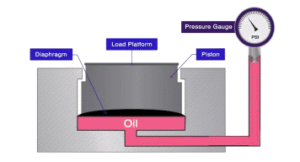

mechanical force and converts the energy of a force into a digital or analog measurable output. The force applied to the load is proportional to the strength of the output. A load cell can use different methods to translate force into a weight measurement. This paper will cover designs according to the type of output signal generated – hydraulic, pneumatic and strain gauge. The most common load cell used in industrial weighing are strain gauge load cells.

mechanical force and converts the energy of a force into a digital or analog measurable output. The force applied to the load is proportional to the strength of the output. A load cell can use different methods to translate force into a weight measurement. This paper will cover designs according to the type of output signal generated – hydraulic, pneumatic and strain gauge. The most common load cell used in industrial weighing are strain gauge load cells.

heavy the

heavy the

Determining which load cell your

Determining which load cell your  were erratic and they were having to start and stop the process manually. The process was so troublesome that the brewer was intentionally overfilling kegs just to make sure they were not shorting their customers. The brewer was getting an ‘Error 900’ message, but after scouring their paperwork and the internet, no one could find that error message ANYWHERE! The kegging system was a European system with a European flow meter. The brewer was resigned to the fact that he was going to have to pay a technician to come from Europe to help identify and fix the flowmeter.

were erratic and they were having to start and stop the process manually. The process was so troublesome that the brewer was intentionally overfilling kegs just to make sure they were not shorting their customers. The brewer was getting an ‘Error 900’ message, but after scouring their paperwork and the internet, no one could find that error message ANYWHERE! The kegging system was a European system with a European flow meter. The brewer was resigned to the fact that he was going to have to pay a technician to come from Europe to help identify and fix the flowmeter.

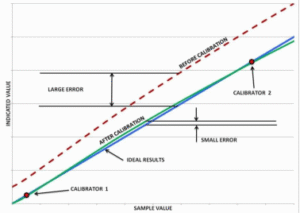

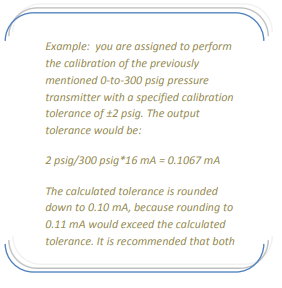

“Ideal Results”. However, without calibration, an actual product may produce test results different from the sample value, with a potentially large error. Calibrating the product can improve this situation significantly. During calibration, the product is “taught” using the known values of Calibrators 1 and 2 what result it should provide. The process eliminates the errors at these two points, in effect moving the “Before Calibration” curve closer to the Ideal Results line shown by the “After Calibration” curve. The error has been reduced to zero at the calibration points, and the residual error at any other point within the

“Ideal Results”. However, without calibration, an actual product may produce test results different from the sample value, with a potentially large error. Calibrating the product can improve this situation significantly. During calibration, the product is “taught” using the known values of Calibrators 1 and 2 what result it should provide. The process eliminates the errors at these two points, in effect moving the “Before Calibration” curve closer to the Ideal Results line shown by the “After Calibration” curve. The error has been reduced to zero at the calibration points, and the residual error at any other point within the

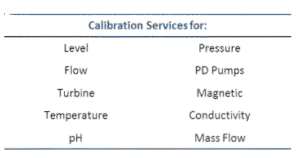

standard is within its calibration interval and the unique identifier is recorded on the applicable calibration data sheet when the instrument calibration is performed. Additionally, when test standards are calibrated, the calibration documentation must bereviewed for accuracy and to ensure it was performed using NIST traceable equipment. M.G. Newell offers a variety of calibration services that keep your operations consistent and cost effective. Contact your local account manager for rates and plan options.

standard is within its calibration interval and the unique identifier is recorded on the applicable calibration data sheet when the instrument calibration is performed. Additionally, when test standards are calibrated, the calibration documentation must bereviewed for accuracy and to ensure it was performed using NIST traceable equipment. M.G. Newell offers a variety of calibration services that keep your operations consistent and cost effective. Contact your local account manager for rates and plan options.