Top Tips to Make Your COP System Work For You – Part 2

Out of Place But In Control

No matter how advanced and automated the CIP system is, there is always a need to clean the parts of production equipment not exposed to the cleaning process. There are pieces of equipment that simply cannot be cleaned where they are used, including piping, fittings, gaskets, valves or valve parts, filler parts and surfaces such as guides or shields, tank vents, tray pack, grinders, pumps, and product handling utensils such as knives. To properly clean and sanitize these units or parts, COP is employed to clean tear-down parts of processing and packaging equipment that require disassembly for proper cleaning. Because COP is essentially the systematic manual cleaning and sanitizing of production equipment that must be disassembled

in many cases, specific attention must be paid to cleaning underneath and around gaskets, O-rings, small pipes and other small surface cavities, gaps or other niches and harborage points in which potentially harmful residue and bacteria may accumulate. Cleaning knives or spoons that are used in a plant’s dishwasher would be considered a COP operation. In food plants, a common use of the COP cleaning method involves pieces of equipment that are small, complex and otherwise hard to clean. They are dissembled, rinsed and then cleaned and sanitized. COP may occur in a sink with a worker scrubbing to clean, or in tanks specially designed for COP. In these tanks, detergent and agitation are used to clean the equipment in question. Sanitizing may be done using hot water or chemical sanitizers. Small items, such as valves, sanitary fittings and such, can be placed in cages and cleaned with larger items. Options include doing a rinse, hot water wash with detergent, rinse and soak in sanitizer. Operators can also sanitize COP items by raising the second rinse temperature and holding for 15 minutes at >180F.

The basic steps in a COP operation include:

• Dry cleaning to remove dust, soil and other debris from the equipment to be cleaned and the area in which COP tasks will take place.

• A pre-rinse of the equipment and area on racks or in COP tanks.

• Soap and scrub the equipment and equipment components in COP tanks or vessels.

• Post-rinse parts to remove residual detergent or cleaning chemicals.

• Conduct pre-operational procedures and sanitize any equipment components that are not accessible once reassembled. Reassemble the equipment.

• Sanitize the reassembled equipment with a sanitizing agent or heat treatment.

Although the following tips for effective COP may seem obvious, they are well worth review:

Tip 1. Conduct COP tasks in order. It is important to understand that sanitation is a sequence of steps that build from the successful completion of the previous steps. In particular, COP practices, which involve multiple individuals working in the same area, multiple small parts to be cleaned and multiple sanitation steps for each item to be cleaned, are ineffective when steps are not taken in sequence. For example, it is not difficult to understand that the level of cross-contamination risk is raised if personnel are not all working at the same step at the same time. If one individual in that area is doing a final rinse while another person is doing a pre-rinse and the equipment is adjacent to each other, there is a risk of overspray from the unsanitized surface to the

sanitary one.

Tip 2. Consider using basket or tote washers. Another COP system that is of great value is comprised of basket or totes washers. Companies, such as those in the fresh-cut industry, who use a large number of small containers in their process operations, should look at these units. The container is simply loaded onto the system and it passes through the unit where it is rinsed, washed and rinsed. The cleaned containers should then be stacked so that they will not become re-contaminated. These washers may also be used for steel trays, pots or totes used in meat operations. A washer like this is usually much more effective than having an employee individually clean each and every tote, basket or pot. Tote washers, in particular, are usually designed to filter debris and reuse water, which can translate into reductions of water and chemical usage.

Tip 3. Use a tank rather than a rack. Parts removed for cleaning are either placed on a rack for cleaning or placed in a COP circulation tank and cleaned using a heated chemical solution and agitation. There are advantages to using a tank versus a rack, including:

• Parts may be cleaned all at once rather than individually which can be a time saver.

• The ideal vat or tank is stainless steel and sufficient size to fully submerge all parts, and will have smooth welds and no dead spots so that it will not be a source of contamination itself

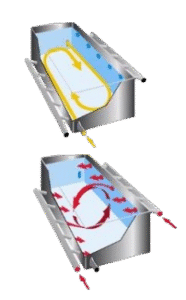

• After dry cleaning major soil off the parts, they are placed in the tank and water is added to the tank that is either hot (125-130F) or will have steam injected to achieve that temperature.

• Once the cleaning chemical is added, turbulence will be created, either from steam or mechanical means to aid in loosening soil.

When parts are clean, rinse thoroughly with clear potable water, inspect and sanitize. Parts may either be reassembled or stored on a rack until ready for use. One caution: Many COP operations are carried out by staff on production floors. They will literally work on the floor or on temporary tables. While the equipment and components may get clean, control is questionable.

Tip 4. Make sure the mechanical action tools used in COP tasks do not contribute to potential contamination. Since COP requires manual washing, or scrubbing, by staff for adequate soil removal and cleaning, the tools used take on critical significance. Make sure that cleaning brushes are rugged, made of non-absorbent material with bristles that are resistant to retaining soils and that dry quickly. Hand brushes and floor brushes should be color-coded to ensure that those designated for use on food contact surfaces are not used on non-food contact surfaces. The same goes for buckets, pails, utensils and other cleaning tools that are portable. These tools should undergo specific cleaning and sanitizing, as well, either with chemicals in a

dedicated wash-and-rinse sink unit or via heat treatment.

utilized for pieces of equipment and utensils that cannot be cleaned where they are used and must be disassembled, and for pieces of equipment that are complex and hard to clean. With a greater emphasis on sanitary design in food plants, equipment manufacturers and industry have worked together to make many improvements to equipment and parts that make cleaning and sanitizing more effective. Even so, plant sanitation crews and quality assurance/quality control (QA/QC) managers cannot rely solely on the fact that equipment is more cleanable today than in the past. Introducing or improving CIP and COP procedures, processes and systems in the food plant takes advantage of sanitary equipment design benefits, raising the level of assurance that when the production line starts up for a new run the process is in control from the get-go. With this in mind, here are a few tips to best-practice approaches in using CIP and COP systems to their fullest potential as process control measures.

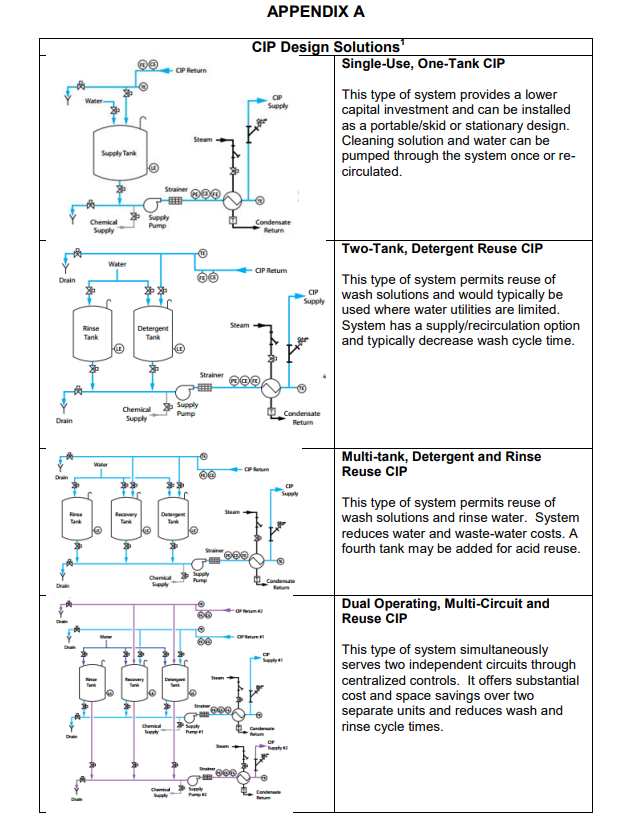

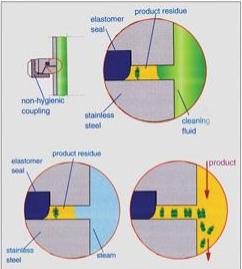

utilized for pieces of equipment and utensils that cannot be cleaned where they are used and must be disassembled, and for pieces of equipment that are complex and hard to clean. With a greater emphasis on sanitary design in food plants, equipment manufacturers and industry have worked together to make many improvements to equipment and parts that make cleaning and sanitizing more effective. Even so, plant sanitation crews and quality assurance/quality control (QA/QC) managers cannot rely solely on the fact that equipment is more cleanable today than in the past. Introducing or improving CIP and COP procedures, processes and systems in the food plant takes advantage of sanitary equipment design benefits, raising the level of assurance that when the production line starts up for a new run the process is in control from the get-go. With this in mind, here are a few tips to best-practice approaches in using CIP and COP systems to their fullest potential as process control measures. removed. It is important that tanks are properly vented, are self-draining and that the floor of the vessel allows for fast flushing. Figure 1 aptly illustrates the the contamination that can occur when equipment components such as coupling is not of sanitary design. If the only treatment materials that will be used in or flow through the system during CIP are rinse water and cleaning solution, a two-tank system will likely be adequate. If your process requires an additional function, such as an acid wash or retention of final rinse water, a three-tank or return pump system is warranted. Since CIP systems vary in application and sophistication, check with CIP equipment manufacturers to ensure that a system is right for your operation. Also make sure that there are a sufficient number of tanks for the cleaning solutions used and that they can contain sufficient quantity, about 50 percent more solution, than required to avoid running out of solution. Similarly, check that the spray balls used to deliver the cleaning agents to the interior surfaces of the equipment are actually appropriate for the tanks in which they are employed. Spray balls are designed to work within specified conditions and parameters involving flow rate, pressure and shape of the tank(s) in the circuit. If the spray balls are tampered with, damaged or not maintained in good condition, the distribution of the cleaning and sanitizing chemicals will be ineffective.

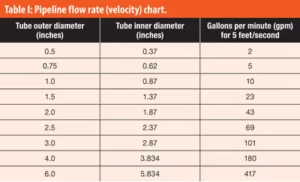

removed. It is important that tanks are properly vented, are self-draining and that the floor of the vessel allows for fast flushing. Figure 1 aptly illustrates the the contamination that can occur when equipment components such as coupling is not of sanitary design. If the only treatment materials that will be used in or flow through the system during CIP are rinse water and cleaning solution, a two-tank system will likely be adequate. If your process requires an additional function, such as an acid wash or retention of final rinse water, a three-tank or return pump system is warranted. Since CIP systems vary in application and sophistication, check with CIP equipment manufacturers to ensure that a system is right for your operation. Also make sure that there are a sufficient number of tanks for the cleaning solutions used and that they can contain sufficient quantity, about 50 percent more solution, than required to avoid running out of solution. Similarly, check that the spray balls used to deliver the cleaning agents to the interior surfaces of the equipment are actually appropriate for the tanks in which they are employed. Spray balls are designed to work within specified conditions and parameters involving flow rate, pressure and shape of the tank(s) in the circuit. If the spray balls are tampered with, damaged or not maintained in good condition, the distribution of the cleaning and sanitizing chemicals will be ineffective. essentially “scrubbed.” This means the flow must be greater than 5 ft. per second. To achieve this flow rate, operators need to understand their specific processing system. To do this, make sure that pump sizes are sufficient for the size of the tank or length of pipes to be cleaned. The rule of thumb is that the pump can produce a flow rate four to five times the rate of the product flow. For example, turbulent flow may be achieved in a one-inch pipe at a flow rate of 24 gallons per minute (gpm), whereas a four-inch pipe requires a flow rate of 180 gpm. The same holds true for tanks, ovens or other large vessels. To calculate proper flow in a tank, take the circumference in feet times two. This will give the user a minimum flow in gpm needed to clean the tank and sufficient volumes of cleaner flowing down the sides of the tank for turbulent flow.

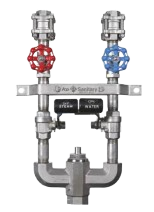

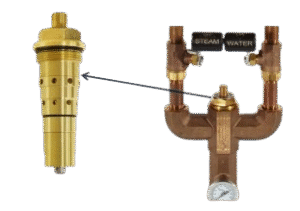

essentially “scrubbed.” This means the flow must be greater than 5 ft. per second. To achieve this flow rate, operators need to understand their specific processing system. To do this, make sure that pump sizes are sufficient for the size of the tank or length of pipes to be cleaned. The rule of thumb is that the pump can produce a flow rate four to five times the rate of the product flow. For example, turbulent flow may be achieved in a one-inch pipe at a flow rate of 24 gallons per minute (gpm), whereas a four-inch pipe requires a flow rate of 180 gpm. The same holds true for tanks, ovens or other large vessels. To calculate proper flow in a tank, take the circumference in feet times two. This will give the user a minimum flow in gpm needed to clean the tank and sufficient volumes of cleaner flowing down the sides of the tank for turbulent flow. steam would bore out the inner working components in the washdown system. Safety had become an issue. The needle valves, once bored out, would not fall back into the saddle correctly. Once that occurred, a steam backdraft was created which would come out of the spray nozzle. These bursts of steam and extremely hot water were a huge safety risk for their associates. Casey O’Rear, our account manager in GA, listened to their concerns and decided to present the Ace Sanitary Silent Type Venturi Mixer (STVM) wash down station to the Safety Manager. The STVM uses a venturi mixing valve that combines steam and water for a constant stream at the operator’s set temperature. He brought in a sample that showed how easy it is to remove and replace the patented venturi cartridge and illustrated the safety shutoff feature if the water exceeds the factory set temp.

steam would bore out the inner working components in the washdown system. Safety had become an issue. The needle valves, once bored out, would not fall back into the saddle correctly. Once that occurred, a steam backdraft was created which would come out of the spray nozzle. These bursts of steam and extremely hot water were a huge safety risk for their associates. Casey O’Rear, our account manager in GA, listened to their concerns and decided to present the Ace Sanitary Silent Type Venturi Mixer (STVM) wash down station to the Safety Manager. The STVM uses a venturi mixing valve that combines steam and water for a constant stream at the operator’s set temperature. He brought in a sample that showed how easy it is to remove and replace the patented venturi cartridge and illustrated the safety shutoff feature if the water exceeds the factory set temp.  The Safety Manager was very impressed with the safety features inherent in the STVM washdown station. As an added bonus, he was also impressed with the ease of cleaning and switching out the cartridge. The existing washdown system had over 36 internal parts to replace. The STVM system has one cartridge to replace and change out only takes a wrench and a few minutes. The customer only needs

The Safety Manager was very impressed with the safety features inherent in the STVM washdown station. As an added bonus, he was also impressed with the ease of cleaning and switching out the cartridge. The existing washdown system had over 36 internal parts to replace. The STVM system has one cartridge to replace and change out only takes a wrench and a few minutes. The customer only needs  Manufacturing processes using bioreactors and fermenters require a well-thought-out plan to achieve a valid clean. A key consideration during the planning stage is how to successfully integrate an automated system for cleaning processing equipment in place without disassembly, also known as cleaning-in-place (CIP). Designing and sizing a CIP system for sufficient flow and pressure The flow and pressure required to CIP a manufacturing process, such as a bioreactor or fermenter, is dictated by the vessel spray devices and process lines. Static spray balls are the most common spray device used; however, some processes may use rotating impingement spray devices for heavier soil loads. Most standard bioreactor and fermenter designs include a spray device and piping connection package with recommended CIP supply flow rate and pressure requirements. Custom applications require an evaluation to determine spray device and piping design.

Manufacturing processes using bioreactors and fermenters require a well-thought-out plan to achieve a valid clean. A key consideration during the planning stage is how to successfully integrate an automated system for cleaning processing equipment in place without disassembly, also known as cleaning-in-place (CIP). Designing and sizing a CIP system for sufficient flow and pressure The flow and pressure required to CIP a manufacturing process, such as a bioreactor or fermenter, is dictated by the vessel spray devices and process lines. Static spray balls are the most common spray device used; however, some processes may use rotating impingement spray devices for heavier soil loads. Most standard bioreactor and fermenter designs include a spray device and piping connection package with recommended CIP supply flow rate and pressure requirements. Custom applications require an evaluation to determine spray device and piping design.

COP systems are used to clean

COP systems are used to clean