Calibration and Maintenance

Accuracy, Reliability, Repeatability

WHEN YOU NEED THIS

Are you having inaccuracies with your batch weights? Are batch temperatures drifting during the process? The issues in your process may not always be mechanical. However, it could be a calibration issue.

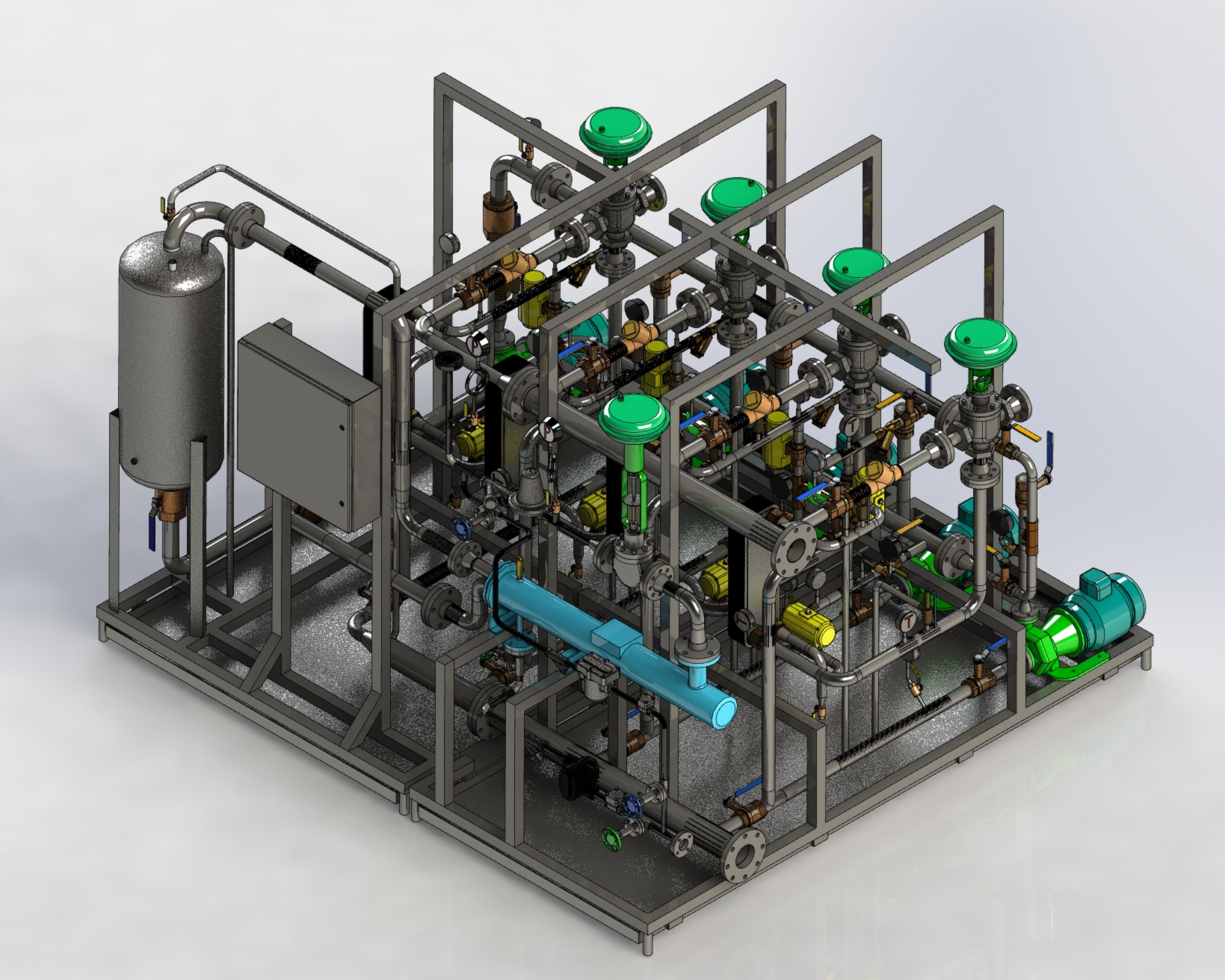

The importance of calibration, maintenance, and repair programs cannot be overlooked in sanitary and hygienic processing operations. The cost of regular maintenance and repair is very small when compared to the cost of major equipment breakdowns, in addition to lost production.

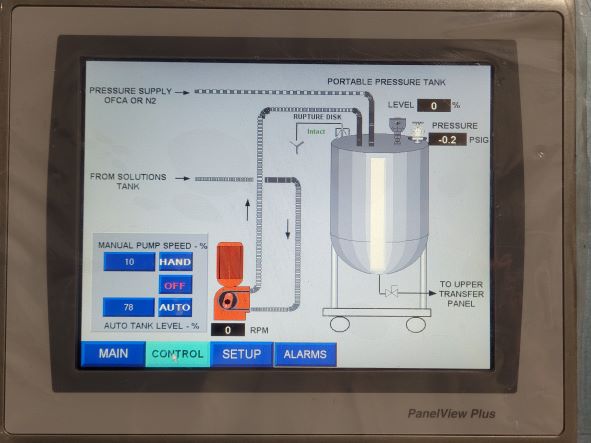

CALIBRATION

Calibration is defined as the activity of checking, by comparison with a standard and also the accuracy of an instrument. It may also include adjustment of that instrument to bring it into alignment with the standard. Instruments definitely need to be calibrated on a regular schedule to:

- Insure readings are consistent with other measurements

- Determine the accuracy of the instrument

- Establish the reliability of the instrument

We Make It Work Better!

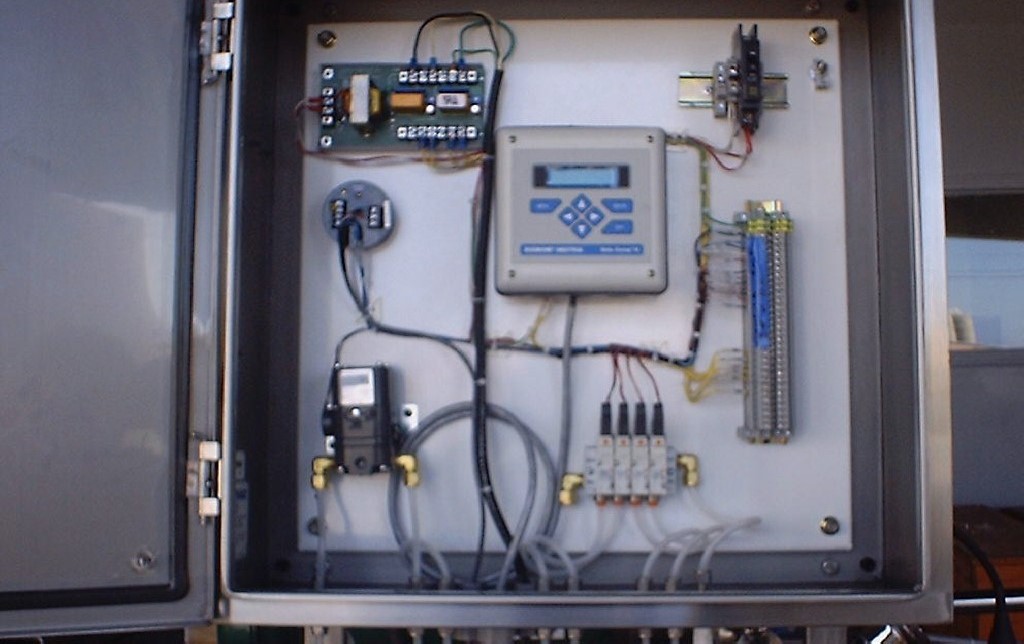

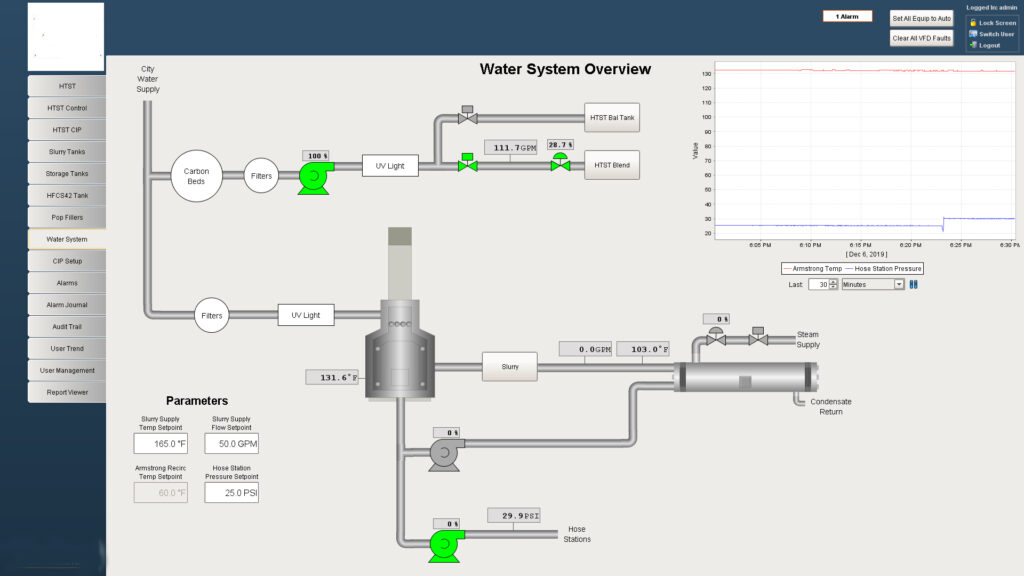

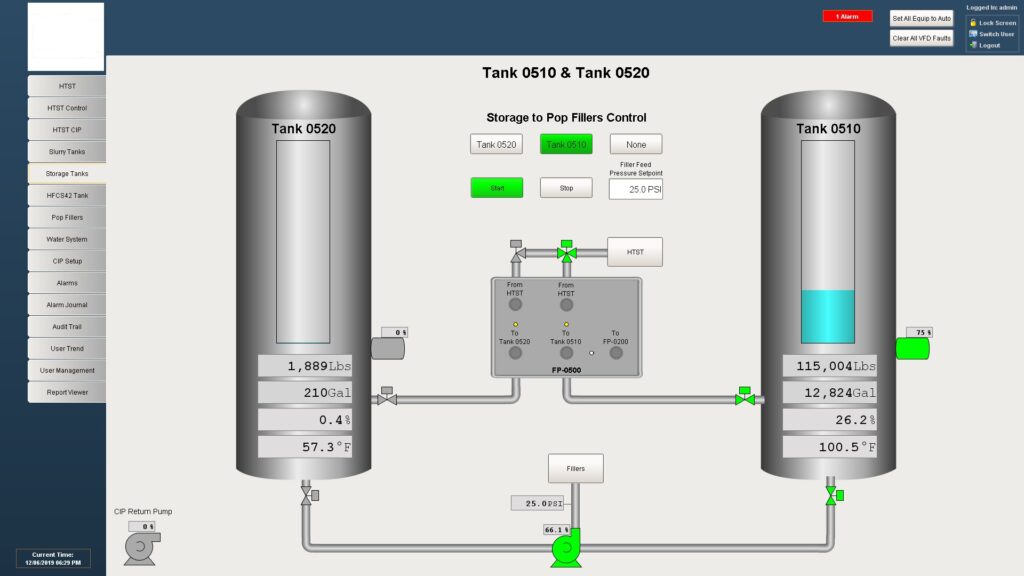

Furthermore because M.G. Newell helps make it work better, we offer a variety of calibration services that keep your operations consistent as well as cost-effective. Hidden costs may be the extra gallons of fructose or glycerin through your meter or the down time added due to incorrect level sensors in your filler. Calibration services are available at your location or in our Greensboro or Louisville shops.

CALIBRATION SERVICES FOR:

- PRESSURE

- CONDUCTIVITY

- LEVEL

- TEMPERATURE

- pH

- CHART RECORDERS

- FLOW including:

- Magnetic

- Turbine

- Mass

- PD Meter

Calibration tools are maintained to NIST traceable standards.

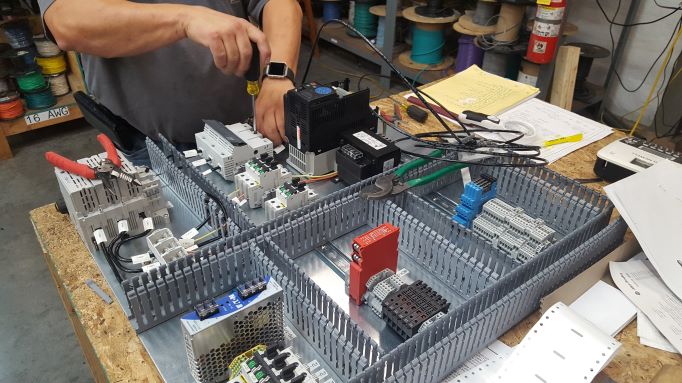

MAINTENANCE

The best way to keep your plant running smoothly and efficiently is to without a doubt prevent problems from happening. How do you do that? You follow a preventive maintenance schedule.

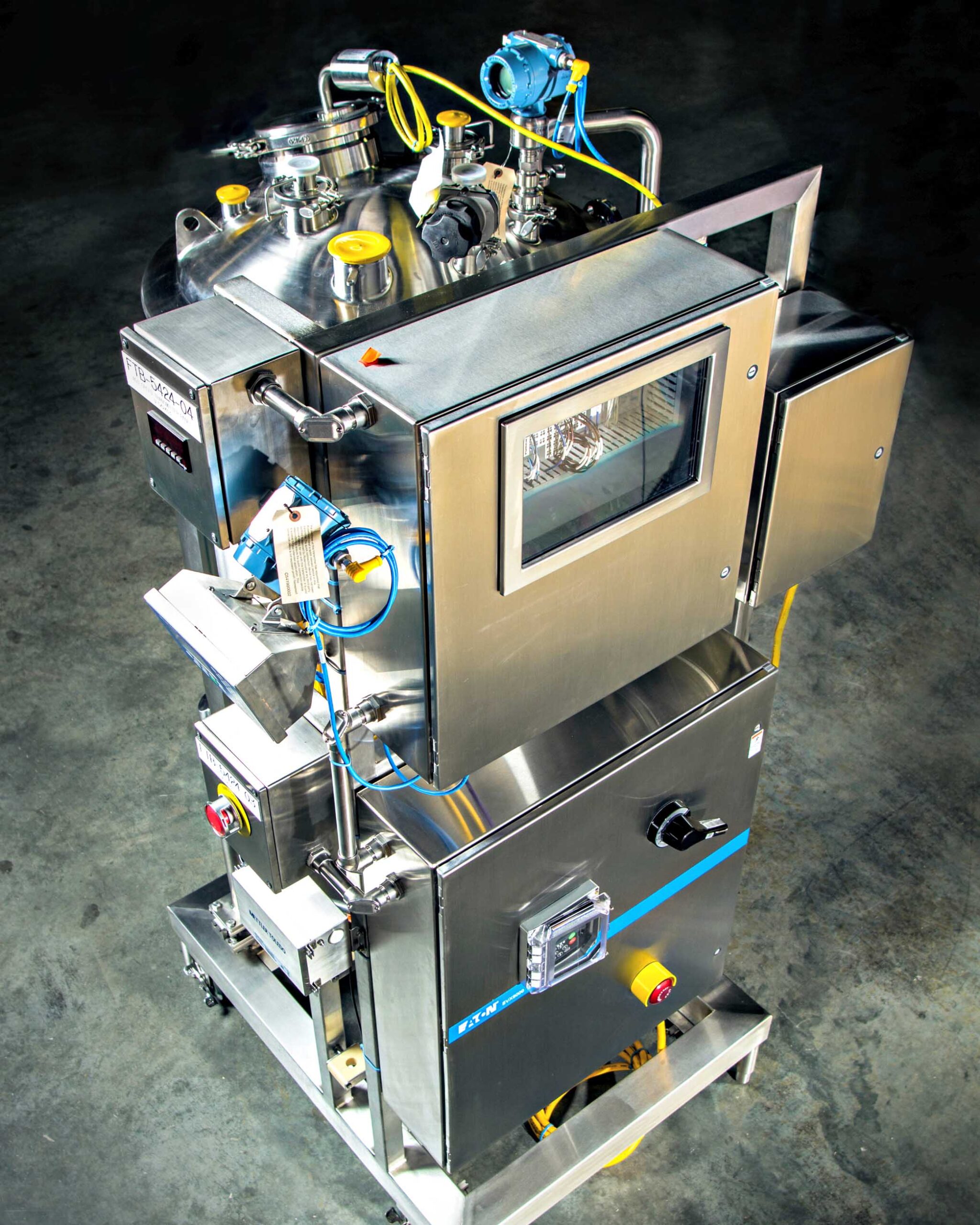

Your local M.G. Newell Representative can offer you a schedule to follow. We offer preventive maintenance on:

- Pumps and pump seals

- Homogenizer plunger packing

- Valve seats

- Votator scrapes

- Plate HEX gaskets

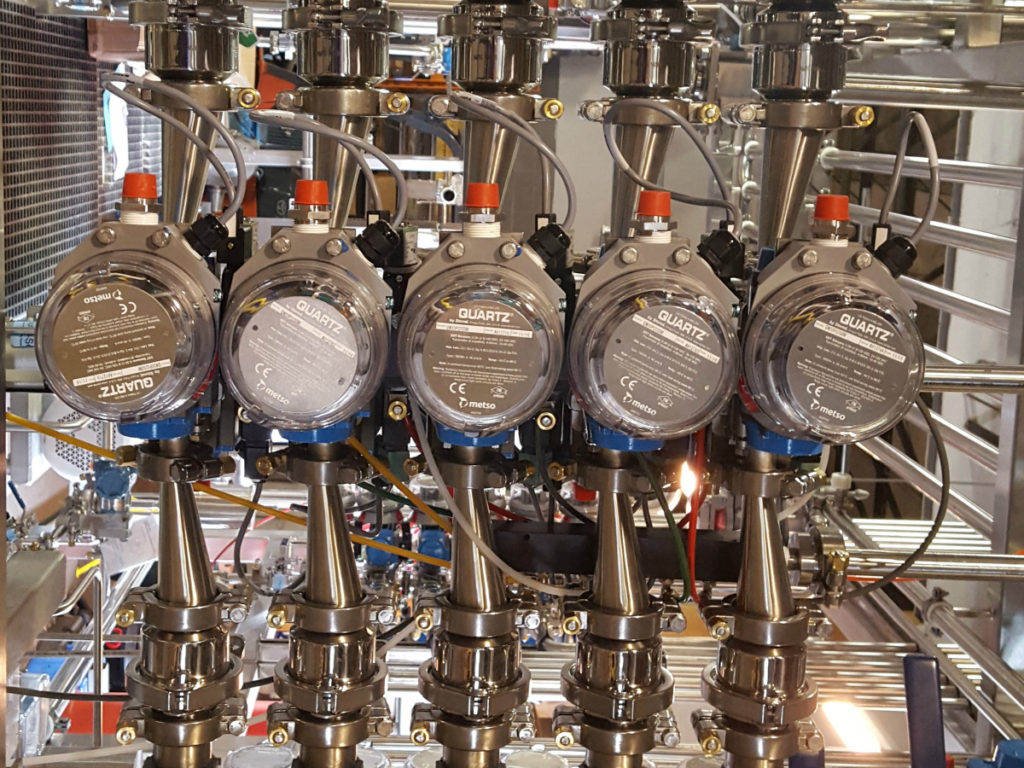

- Valve actuators

SPX Flow Certified Repair Center

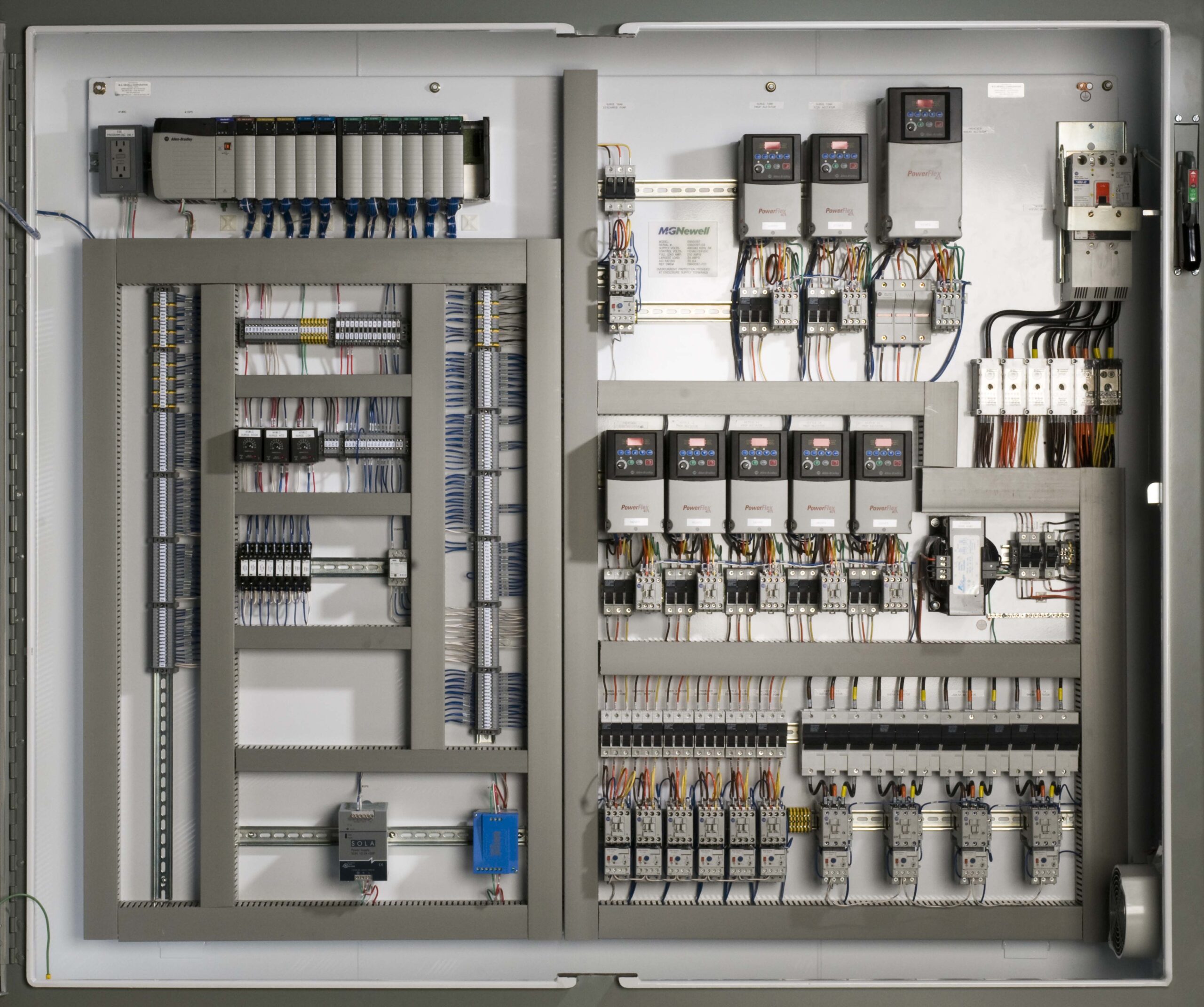

As a Certified Repair Center, M.G. Newell has qualified factory service technicians on staff with over 30 years of experience. Also we have invested in equipment, inventory and training to become one of a select group of distributors that are approved.

"The pumps rebuilt by M.G. Newell's Pump Rebuild program give us better reliability than we get with new pumps."Steve Semans, Sr. Procurement Specialist, ConAgra Foods