Product Spotlight

New Products and Lines

Nuvonic

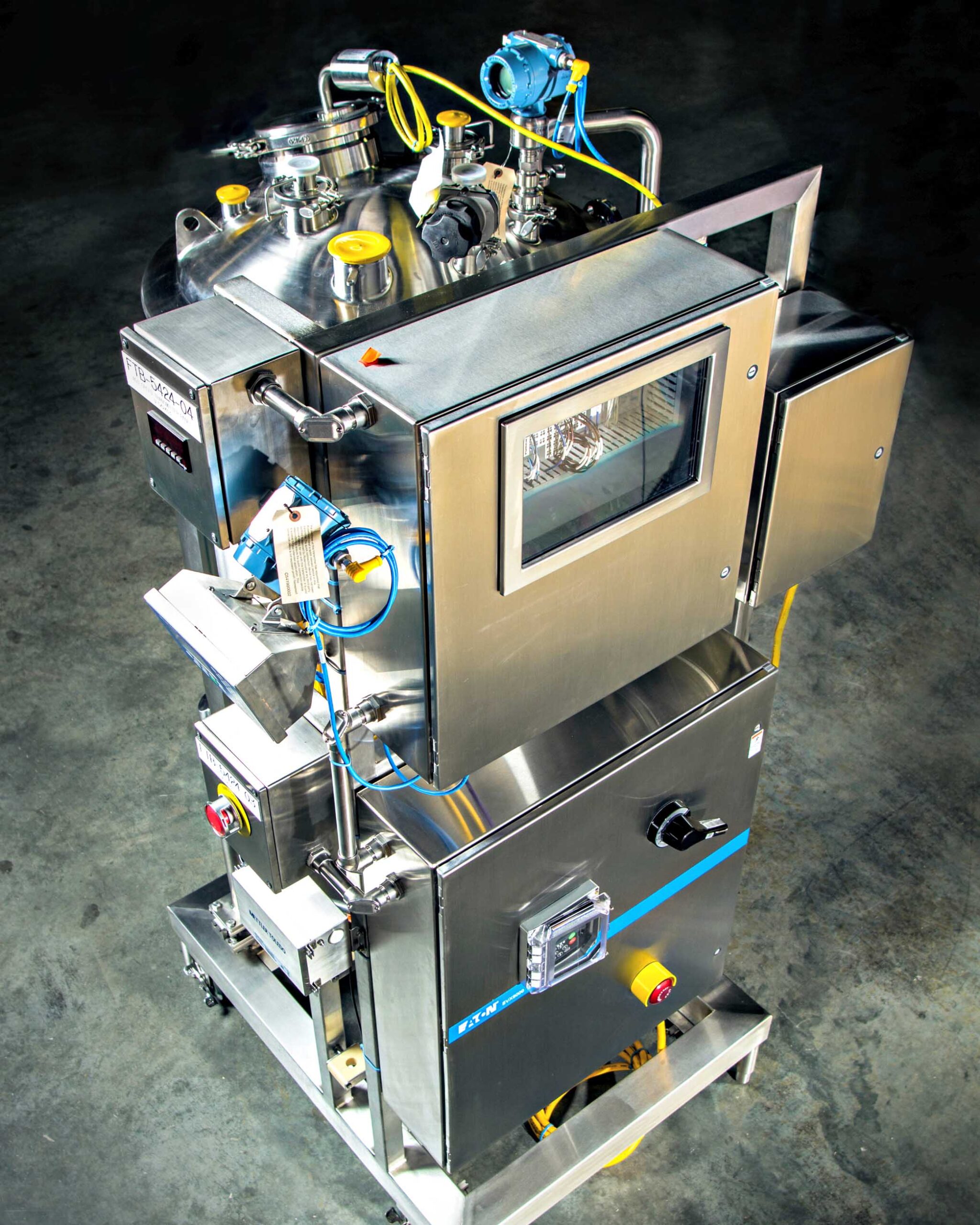

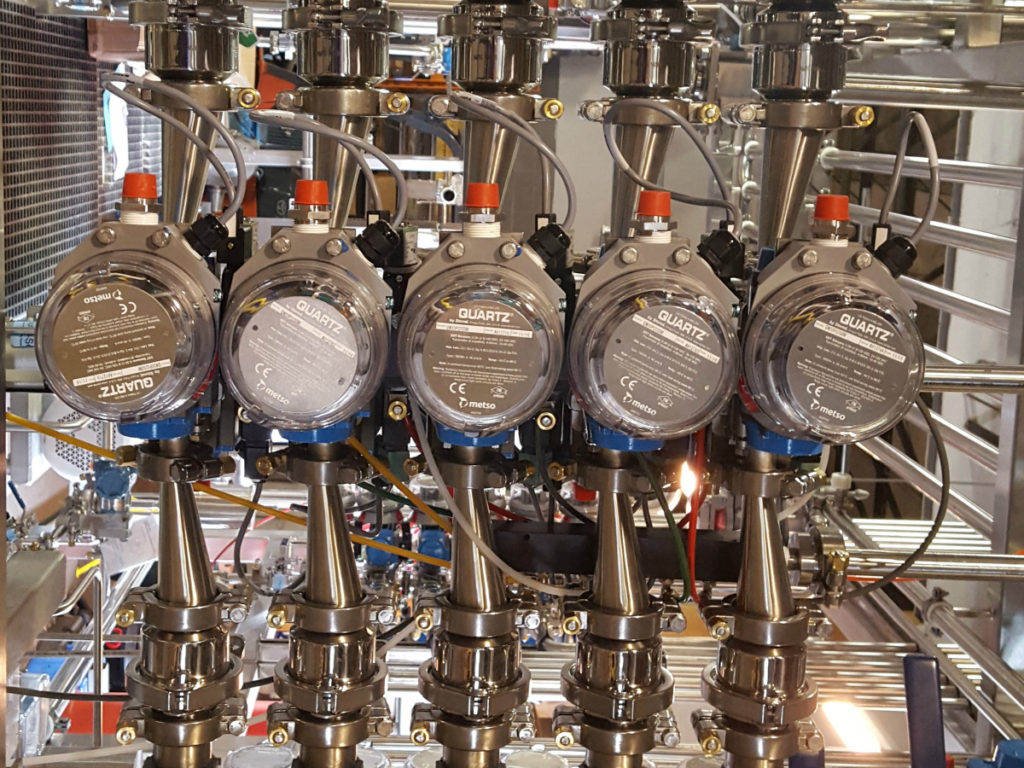

Our PureLine D PH systems are aimed specifically at providing UV treatment for product and process waters used in the food and beverage industry.

Our PureLine D PH systems are aimed specifically at providing UV treatment for product and process waters used in the food and beverage industry.

By using a UV system you will eliminate harmful micro-organisms, reduce the bio-burden, protect against bio-fouling, lead to fewer CIP/SIP cycles and lower operating costs. Each system comes with a UV sensor to measure the active output of the UV system and make it easy to monitor and log performance.

System Cleaners

Open plant cleaning solutions for the food and beverage industry. Sometimes a standard solution will do the job and sometimes it takes a customized one. What matters is that the solution perfectly matches your specific requirements and challenges. No more and no less.

A User’s Guide to VFD Terminology

A VFD is a device that controls the speed of an electrical motor by varying the frequency and voltage of its power supply. The VFD also has ramp-up and ramp-down capabilities to start and stop the electrical motor smoothly.

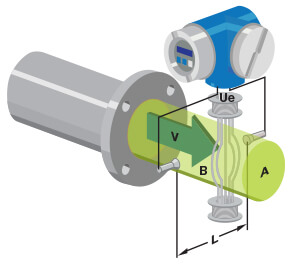

Magnetic Flowmeters - How They Work

Magnetic flowmeters calculate product flow by measuring the change in voltage as the conductive liquid moves through the magnetic field.

Cabinet Washers - Reliable, Consistent Cleaning

Food and beverage manufacturers have a significant number of process items that need to be cleaned daily - and everything needs to be clean quickly to keep production moving.

An Overview of Sanitary Fittings

A sanitary fitting connects different sections of your process – piping to pumps to heat exchangers to tanks. Let’s tip our hat to the sanitary fitting– quite possibly the most used piece of equipment in your plant.

The Perfect Temperature, Every Time - The right heater can provide on-demand hot water at a precise temperature with no energy loss and within a small footprint.

Kest Technology - We are pleased to announce that our partner recently received certification for ISO 9001:2015 and ISO 14001:2015.

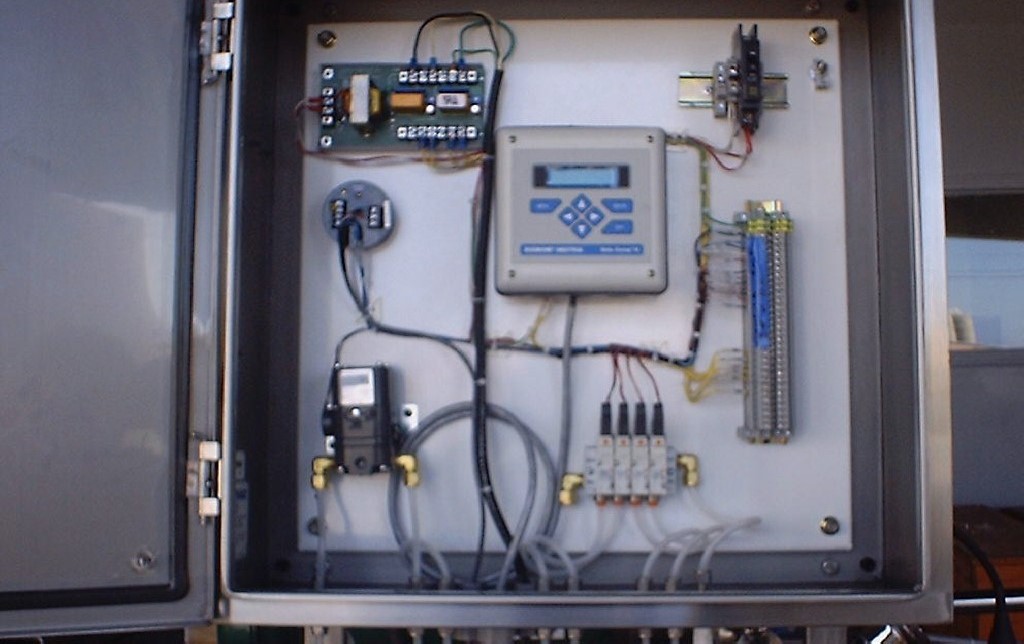

Kest Technology - We are pleased to announce that our partner recently received certification for ISO 9001:2015 and ISO 14001:2015.JBC-100 Batch Controller - Process control at your fingertips. The JBC-100 batch controller puts flow control directly into the hands of the line operator.

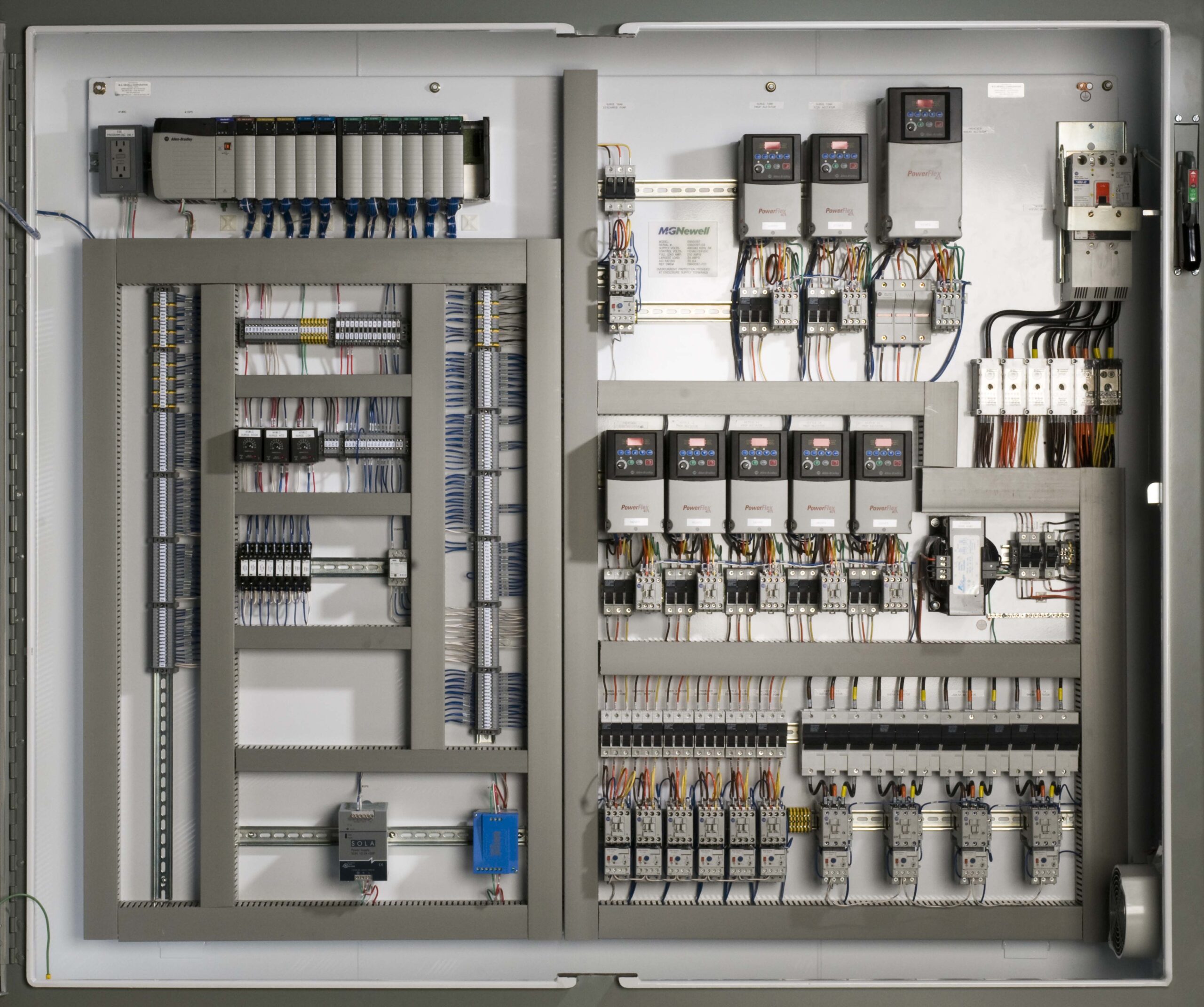

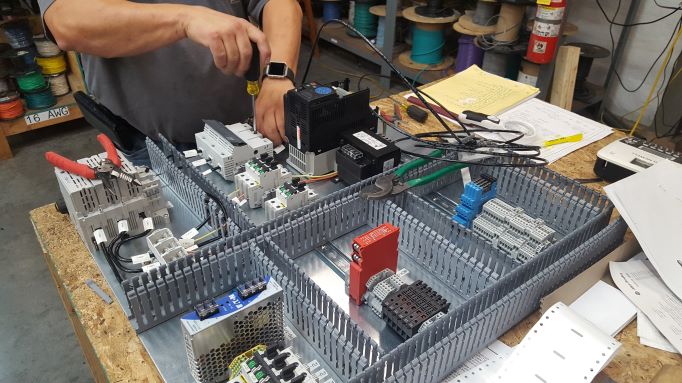

UL Certified - M.G. Newell is pleased to announce that we are now a UL-508A certified panel shop! Congratulations to our entire staff of Controls and Automation engineers and technicians on this milestone achievement!

Graco EODD Pump

QUANTM is the world’s first (and only) affordable electric-operated double diaphragm (EODD) pump built to minimize energy consumption by cutting energy usage and costs by up to 80%.

Optimized tank cleaning is an opportunity for significant savings, although often overlooked.

Optimized tank cleaning is an opportunity for significant savings, although often overlooked.

By optimizing your tank cleaning you can:

- Decrease cleaning times by 70%

- Reduce water and chemical usage by 70-80%

- Reduce or eliminate confined space entry by 100%

- Achieve cleaning effectiveness of 100%

Remember, its not just safer and cleaner tanks you are offering – you are giving them more time, and time is money!

Plate Heat Exchangers - In the food and beverage industry, efficient heat transfer is crucial for maintaining product quality, ensuring safety, and optimizing production processes. One technology that has revolutionized heat transfer in this sector is the Plate Heat Exchanger (PHE). With their compact design and superior efficiency, PHEs offer a range of benefits that make them ideal for food and beverage processing.

Carlton Scale

RapidCalTM Tank Scale Calibration is a new way to calibrate tank scales. It’s similar to calibration with test weights but, in place of weights, it uses hydraulic cylinders to create the downward calibration force with that force measured by high accuracy reference load cells.

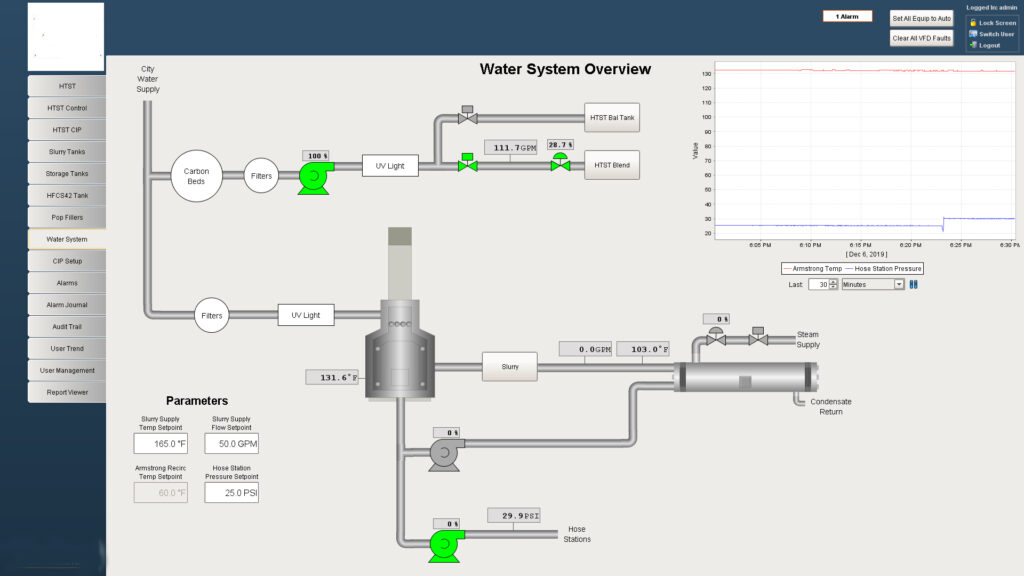

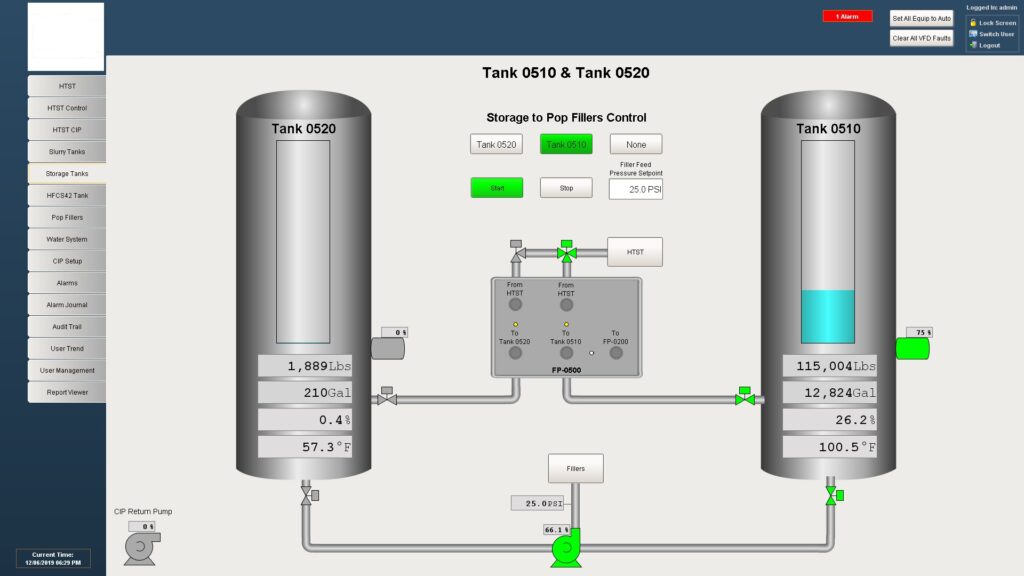

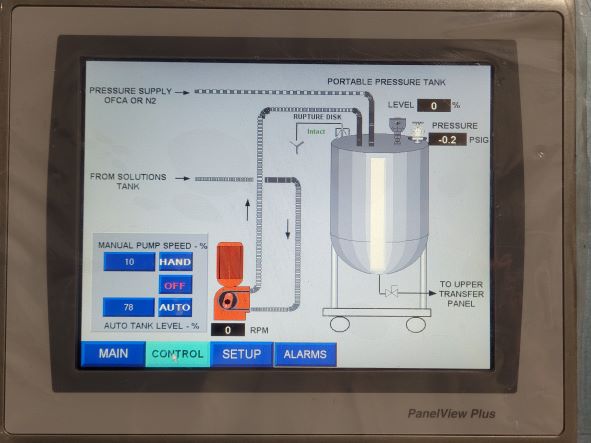

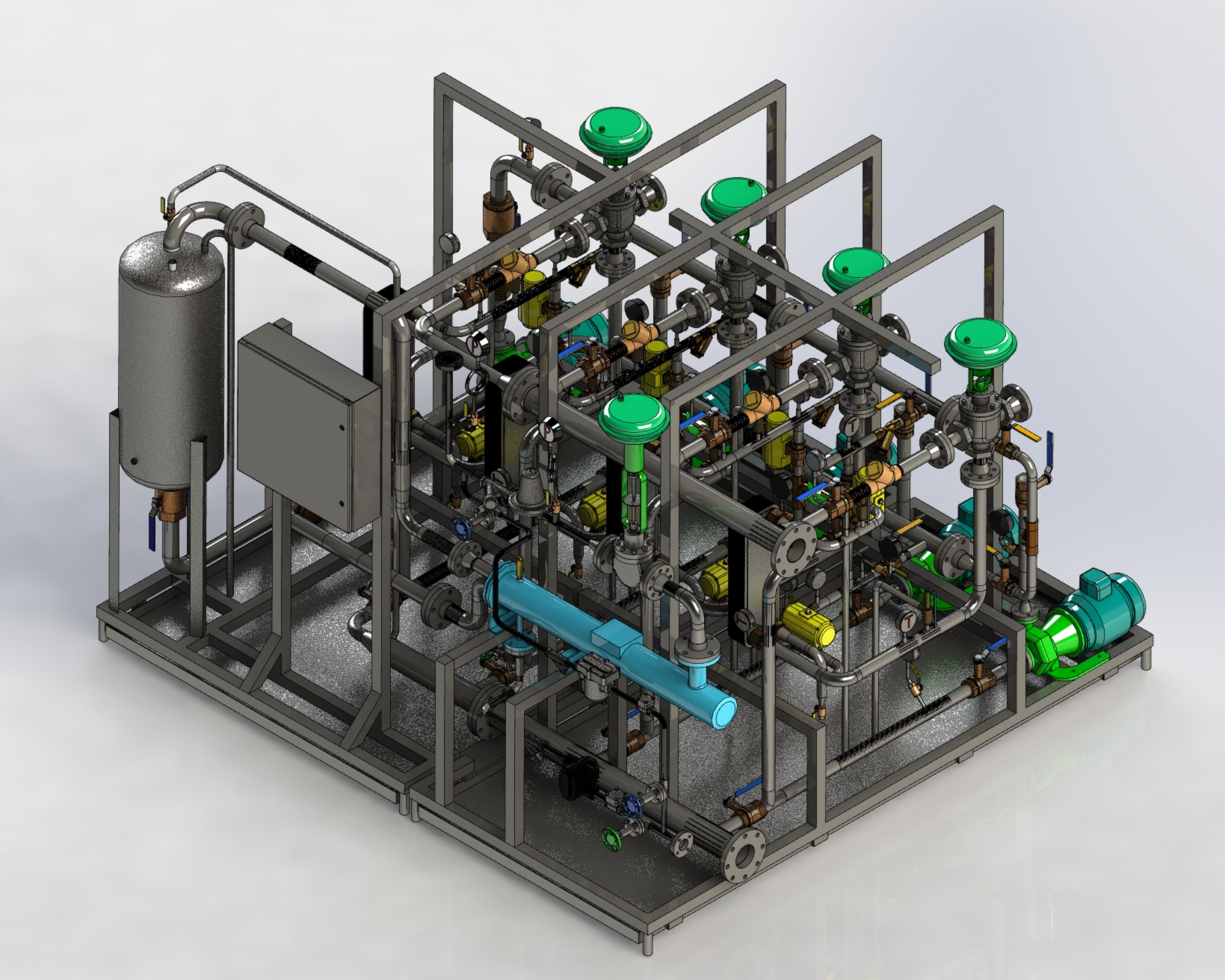

Solving Separation Anxiety with Systems Controls

One would expect a systems control integrator to understand equipment controls. But what happens when your controls integrator also understands the process? You get an improved production process, reduced maintenance, and more productivity!

THE BFM® FITTING DIFFERENCE - Our patented industrial connector technology makes manufacturing cleaner, safer and more efficient – here’s how.

How We Made It Work Better

A Case Study

A juice manufacturer dumped powders into the top of blend tanks which are on a mezzanine about 15’ high. Their process re-circulated pectin through an old-fashioned tri-blender and tank arrangement. They said, “We don’t have a mixing problem.” Sound familiar? However, they were interested in a process to get pectin powder into solution more efficiently.

Sanifan Technology- Stainless Motors Inc. has been manufacturing stainless severe wash-down duty sanitary electric motors and gear motors since 1990 for the pharmaceutical, biotech, and food processing industries.

Steam Water Venturi Mixer - Steam enters the valves through the lower steam inlets and passes through venturi inlets into the mixing chamber.