Sani-Matic

Innovative Cleaning Solutions

M.G. Newell is proud to be a key partner with Sani-Matic. Over the years we have had extensive experience with a variety of their products and provide full engineering as well as technical support to make sure that you are getting the right product for your application.

Since 1943, Sani-Matic, Inc. has designed and manufactured sanitary process cleaning systems and solutions. Sani-Matic manufacture cleaning systems for the food and beverage, pharmaceutical, biotechnology, nutraceutical and personal care industries. They offer a full line of sanitary components and equipment, including Clean-In-Place (CIP) Systems, Clean-Out-of-Place (COP) Parts Washers, cabinet washers, tunnel washers, strainers, spray balls, and more.

Have questions? Contact us about any of the Sani-Matic products.

Equipment

Cabinet Washers

The Sani-Matic SaniCab ® P is an automated, versatile cabinet washer designed to improve food and beverage processors’ productivity and cleaning results for a wide variety of product contact items. These items include scale buckets or weigh hoppers, totes, barrels, piston fillers, trays, buckets, hoses, buggies, and more.

Food, beverage, personal care, and nutraceutical manufacturers face ongoing pressure to increase productivity while also meeting the sanitation preventive controls demands of FSMA and HACCP. With SaniCab cleaning cycles as short as 10 minutes, racks designed to optimize productivity, a sanitary design, and documentation capabilities, manufacturers can achieve both.

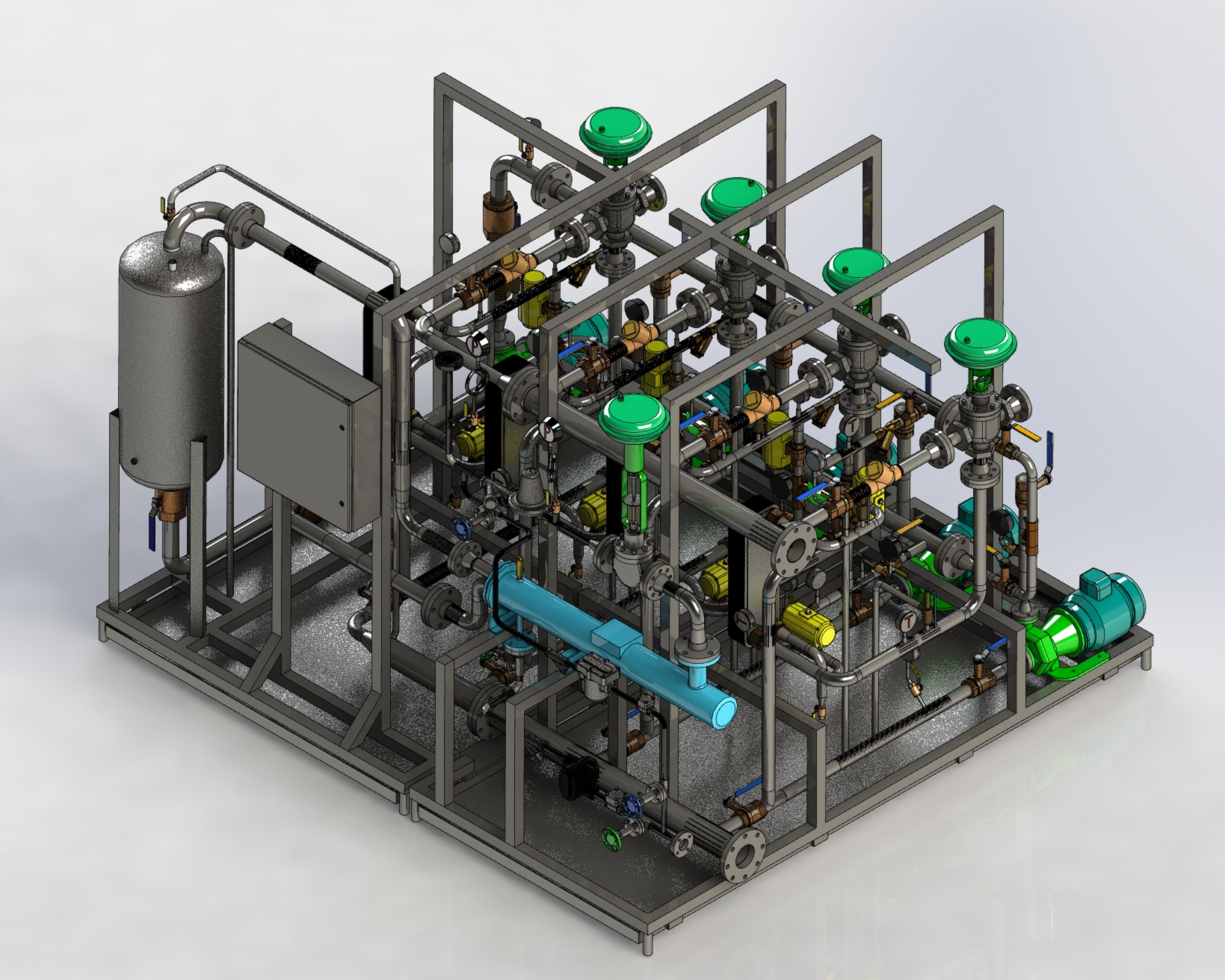

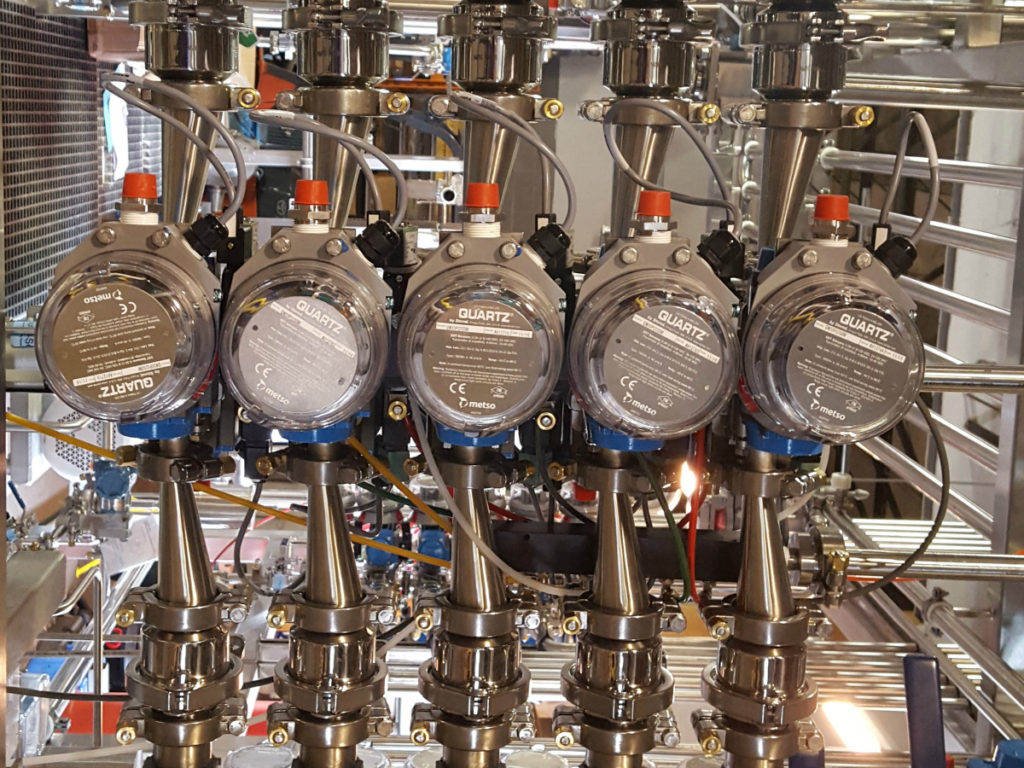

CIP Systems

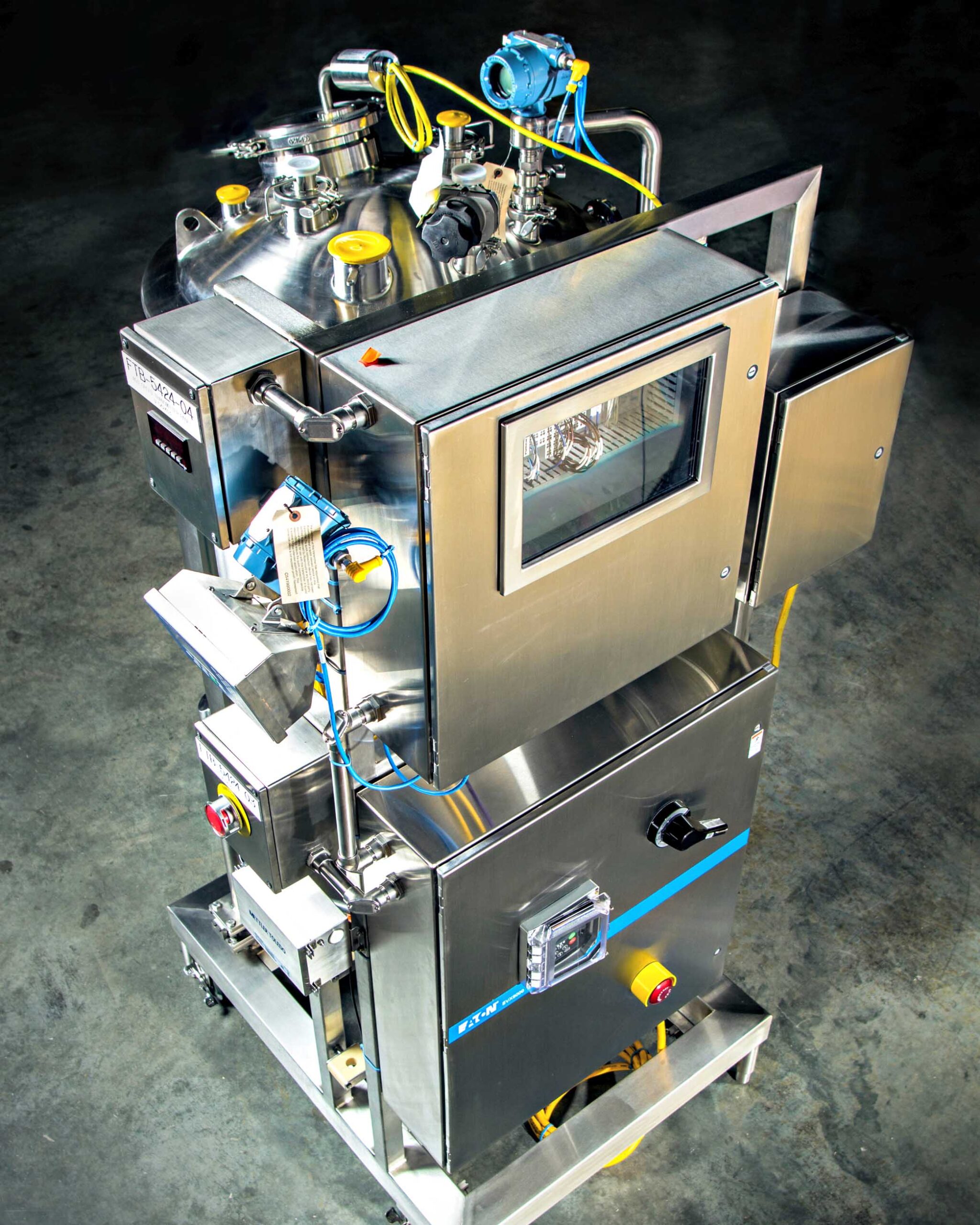

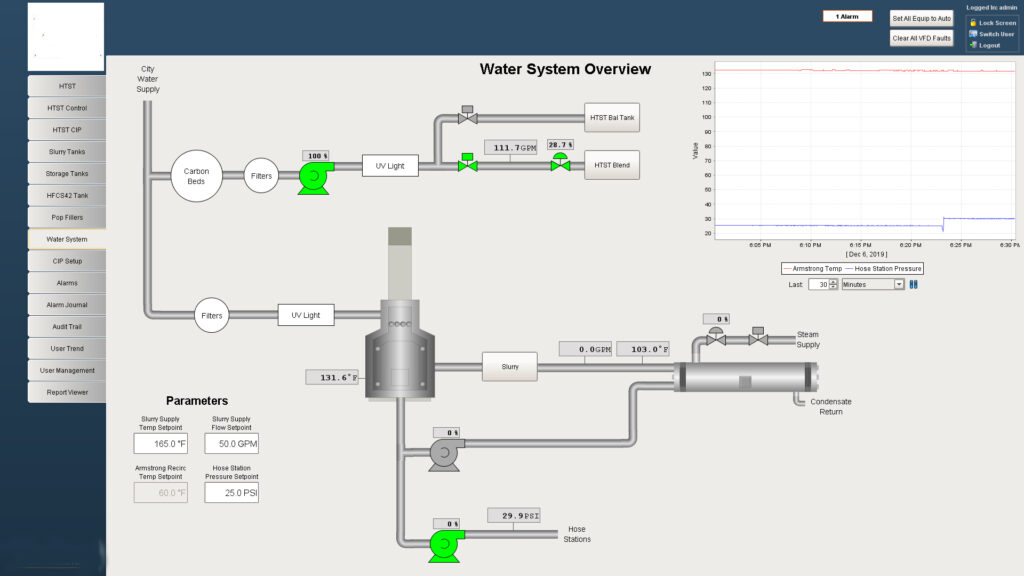

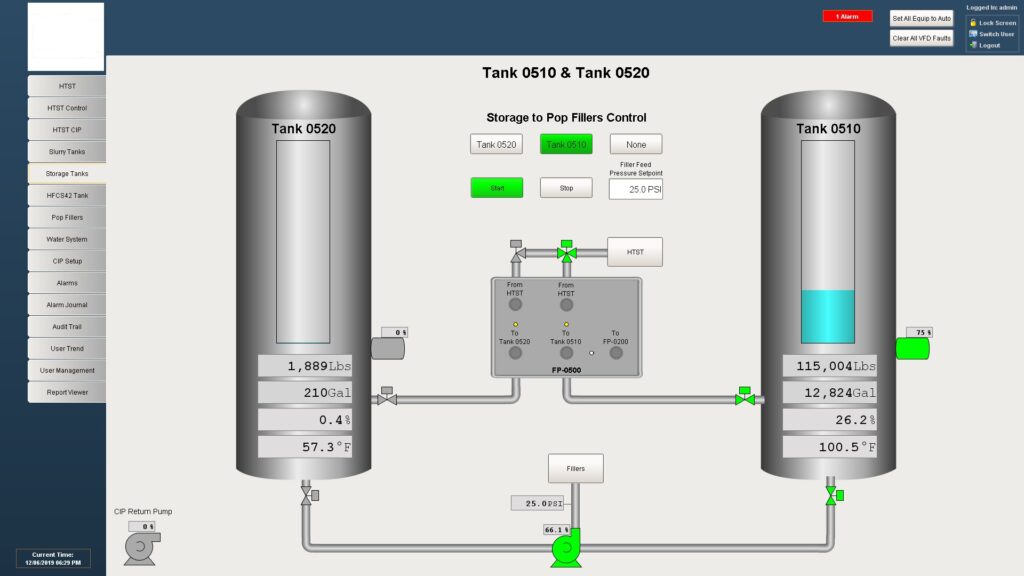

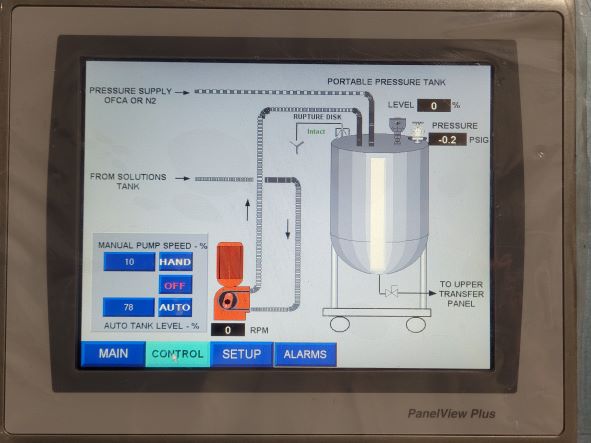

Clean-In-Place ® (CIP) systems are automated systems used to clean the interior surfaces of food and beverage process pipes, processing vessels, tanks, spiral freezers, mixers, blenders, homogenizers, roasters and associated fittings, without disassembling the process. Thorough, repeatable in-place cleaning is critical to the quality of your product, the safety of consumers—and your bottom line.

Sani-Matic CIP Systems are engineered to your specific plant application, layout and utility requirements for effective and efficient sanitary process equipment cleaning. Our application-specific CIP design and sizing ensures sufficient flow. As a result, appropriate pressure is available to thoroughly remove residue, rinse effectively, shorten cycle times and promote worker safety.

Tunnel Washers

The automated Sani-Matic Tunnel Wash ® is designed to thoroughly clean large quantities of process items such as pans, totes or trays, while also generating labor, water, and chemical savings.

Each Tunnel Wash system has high-impact, 360° adjustable spray nozzle manifolds positioned to provide complete cleaning coverage of the process item’s internal and external surface area. The automated system has programmable controls to automate water levels, temperature and conveyor speeds for efficient, repeatable results and cost savings.

The basic Sani-Matic Tunnel Wash modular zone configuration includes detergent and final rinse zones. The most common layout, however, is a three-section tunnel wash that includes a detergent wash, recirculated rinse and final rinse.

Cabinet Washers

Advantages

- Reduced cycle times and labor. Cleaning wash cycle times as short

as 10 minutes, and labor savings up to 75 percent, when compared to

manual cleaning.

- More clean with one machine. With one SaniCab and several parts

racks, a facility can clean process items from totes and hoses to scale

buckets and barrels.

- Automated cleaning. Easy-to-navigate HMI allows operators to

be reassigned from cleaning tasks to production responsibilities.

- Water and chemical savings. Small sump sizes, automated cleaning

cycles, and high-impact cleaning minimize water and chemical usage

compared to water-intensive manual cleaning.

Meets Rigorous Sanitary Standards.

- Repeatable results. A versatile Programmable Logic Controller (PLC)

and HMI with 50 recipes for a sanitary clean, every time.

- Cleaning cycle documentation. Electronic data, chart recorders or

SaniTrendTM Data Acquisition and Management System.

- Cross-contamination prevention. Sanitary open channel frame

design, as well as cleaning cycles programmed to avoid allergen and

bacterial contamination.

Industry Standard

CIP Systems

Advantages

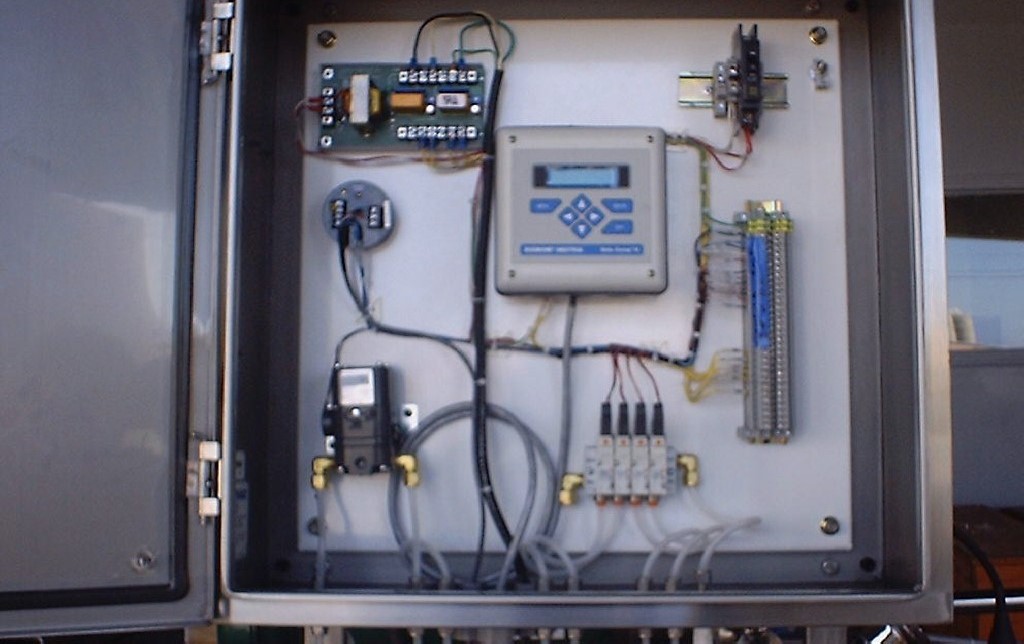

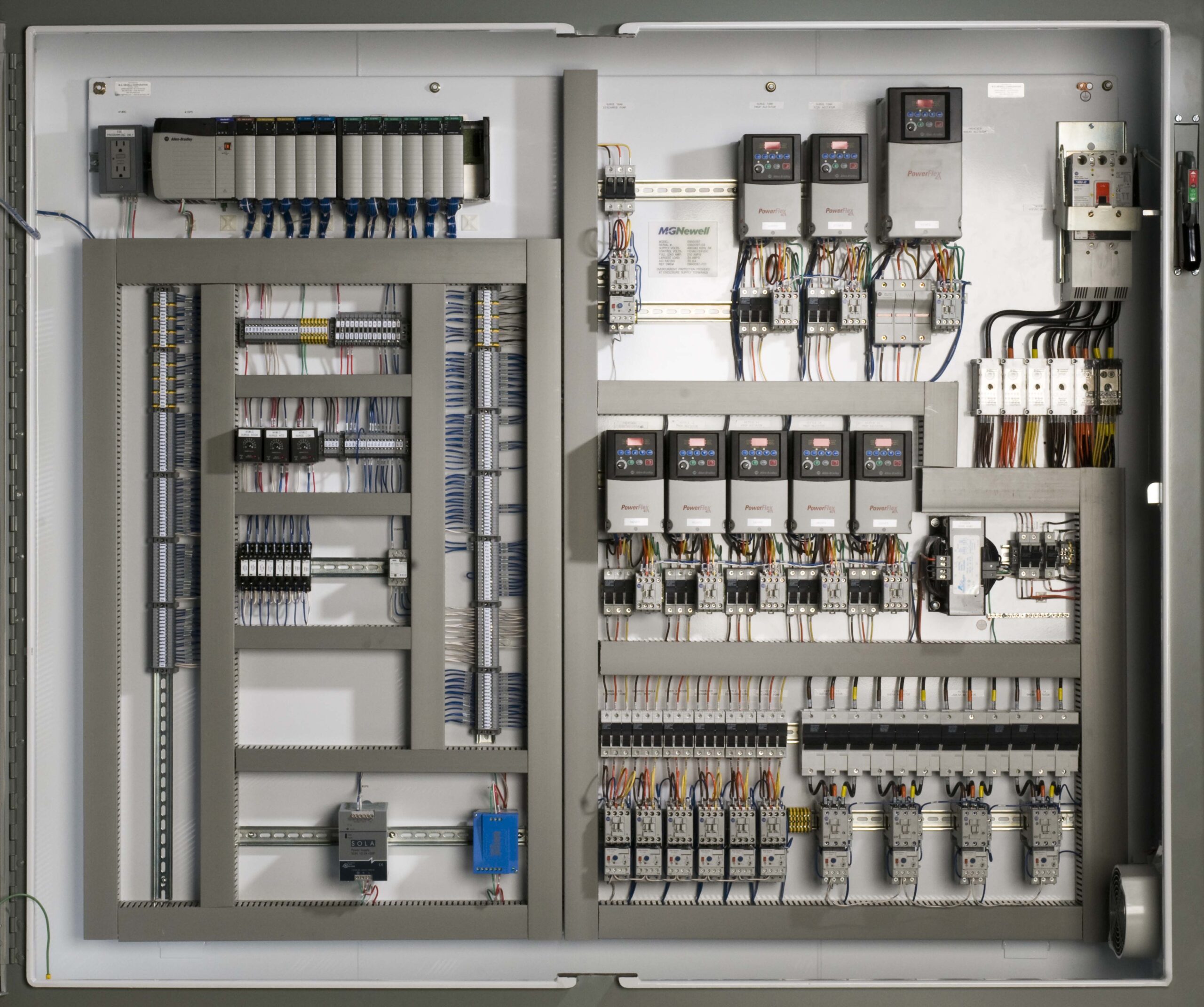

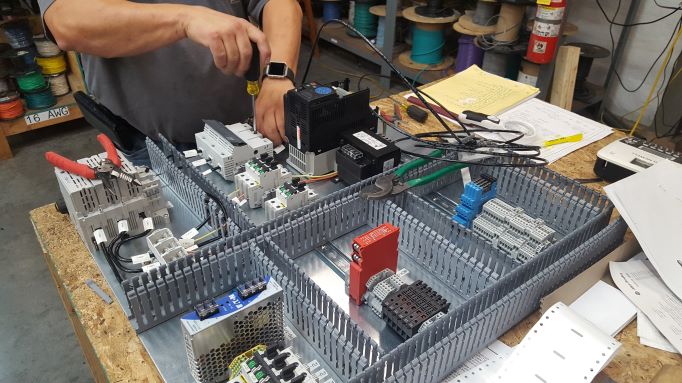

- Programming & Controls. Sani-Matic controls are designed to optimize cycle times and reduce chemical and water use. Ethernet communications interface with individual process control systems for an integrated solution.

- Craftsmanship. Sani-Matic craftsmen have decades of experience constructing sanitary systems and weld to AWS D1s standards.

- Documentation. Complete documentation to comply with regulatory and customer standards is available, as is the SaniTrend data acquisition and management system.

- Services. Sani-Matic’s dedicated service team provides full technical support during the start-up and after installation.

Tunnel Washers

Advantages

- Complete Clean. High-impact, adjustable spray nozzles thoroughly clean a process item's interior and exterior.

- Repeatable Results. Consistent, repeatable results from a controlled process.

- Increased Productivity. Conveyorized and optional exit blow-off systems provide quick turnaround times.

- Savings. Reduces labor and utility costs and controls chemical use.

- Safety. Minimizes operator exposure to high temperatures and strong concentrations. Safe and easy to load and unload.