SPX Flow

Innovative Processing Solutions

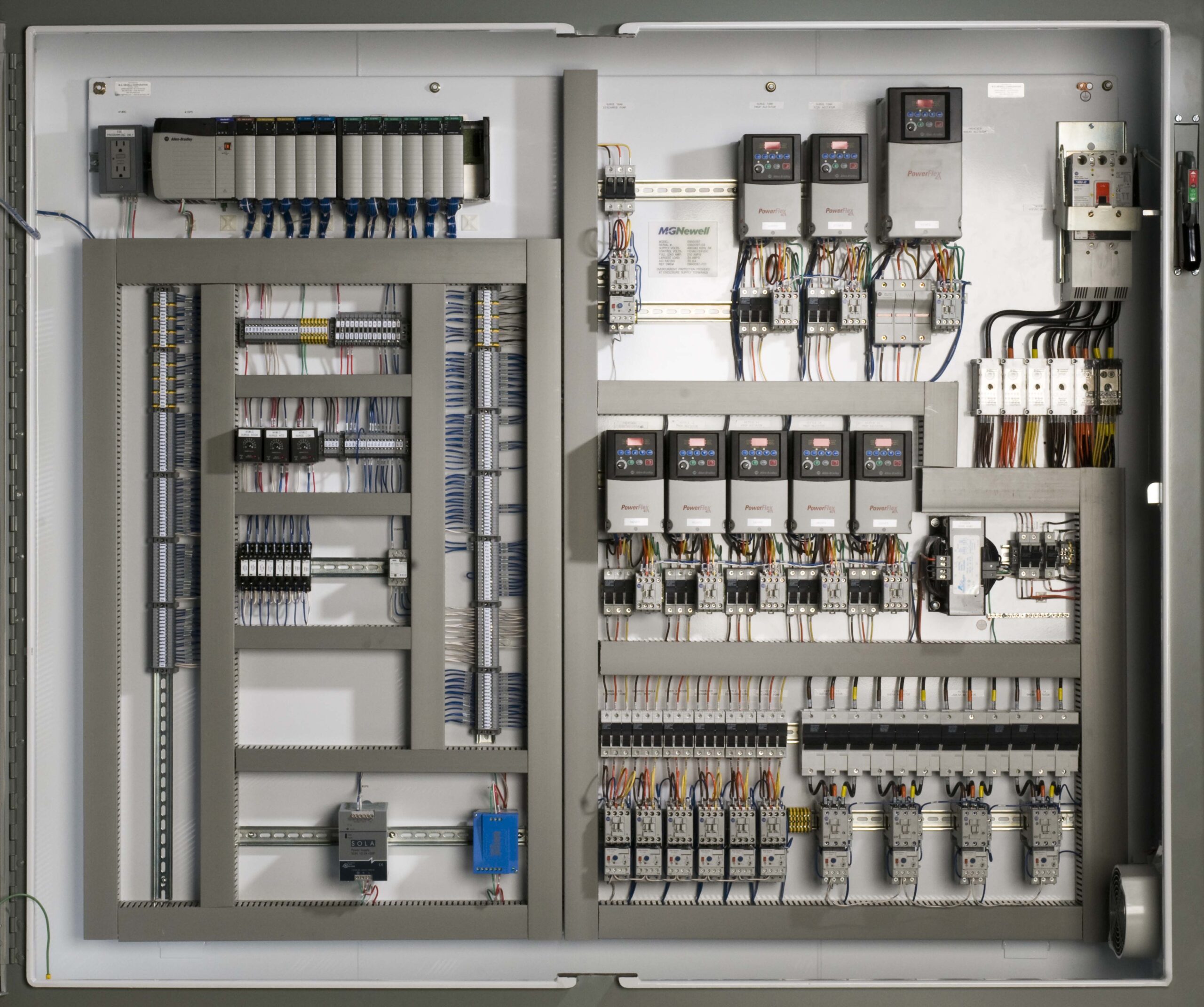

M.G. Newell is proud to be a Certified Distributor for SPX Flow as well as a SPX Flow Certified Repair Center. We have been a distributor for SPX Flow since the 1950’s; that means we have extensive experience with their products and offer full engineering and technical support to make sure you get the right product for your application.

SPX FLOW is a global manufacturing leader in pumps, valves, heat exchangers, homogenizers and separators. Their product range encompasses many brands that are well-known in the sanitary market of food, beverage, and pharmaceutical processing, including:

- Waukesha Cherry-Burrell is their Brand of robust, durable processing technology including positive displacement and centrifugal pumps, valves and the legendary Votator® scraped surface heat exchanger lines.

- APV – an established centennial engineering legacy featuring an extensive array of heat exchangers, pumps, valves, and homogenizers

- Gerstenberg Schröder brand specializes in process solutions for crystallized, churned and emulsified food products

- Seital Separation specializes in leading edge separation and clarification technology

Have questions? Contact us about any of the SPX Flow brands.

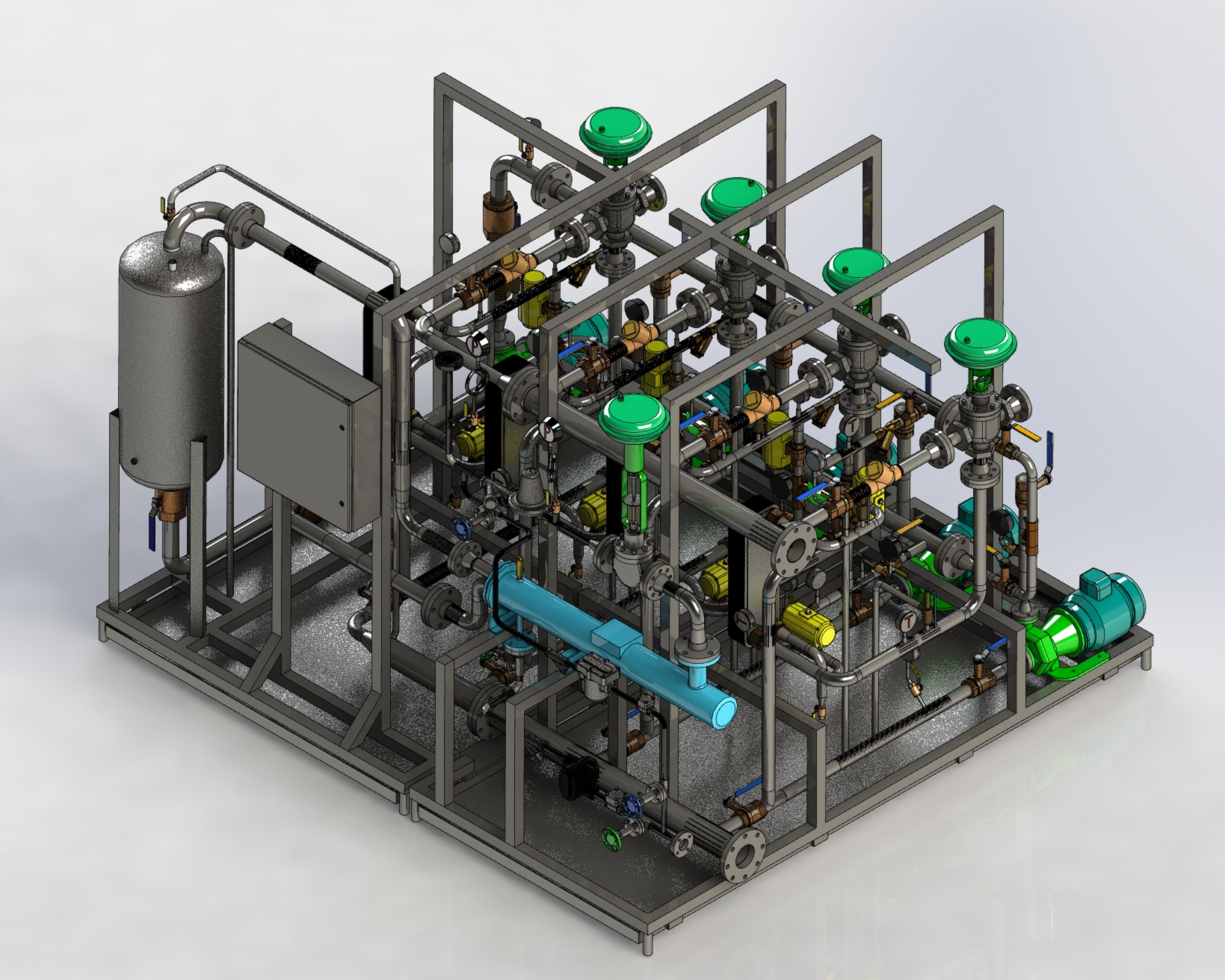

PUMPS

Pumps are typically classified by the way they move fluids. For the sanitary industry, we will only focus on positive displacement pumps and centrifugal pumps.

SPX Flow is our key provider for both pump types. In order to understand which pump works best for your needs, view more details below about the overall performance and function of PD and centrifugal pumps.

POSITIVE DISPLACEMENT PUMPS

Includes single and double rotary lobe pumps, twin-screw and diaphragm pumps. Key features include:

|

Has nearly constant flow regardless of the system pressure or head |

|

Flow is increased when the viscosity is increased |

|

Changing the system pressure or head has little to no effect on flow rate |

|

NPSH varies as a function of flow determined by speed. Reducing the speed reduces the NPSH. |

CENTRIFUGAL PUMPS

Also known as Rotodynamic pumps. Key features include:

|

Has varying flow rate depending on the system pressure or head |

|

Flow is reduced when the viscosity is increased |

|

Changing the system pressure or head dramatically effects the flow rate |

|

NPSH varies as a function of flow determined by pressure |

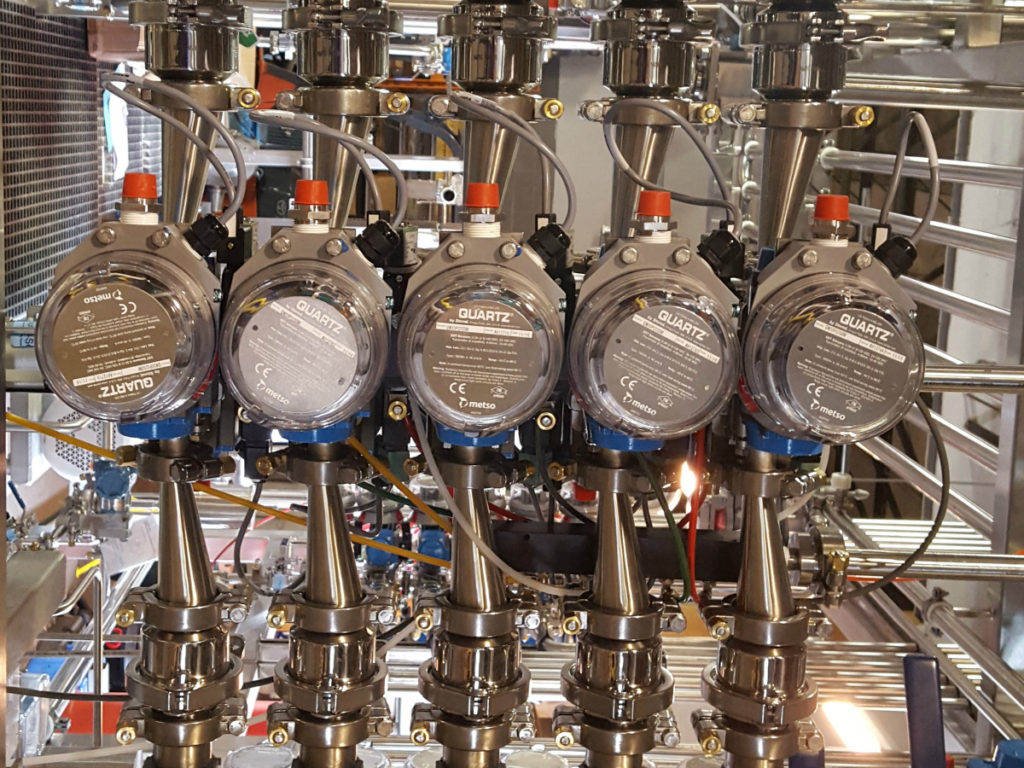

Valves

Stainless steel sanitary valves are the standard in food, beverage and pharmaceutical industries. The corrosion resistance of stainless steel is necessary to cover the wide range of products that may be run through a valve. Whether it’s the low pH of a soda or tomato sauce or the corrosiveness of a CIP solution, stainless steel valves can withstand a wide range of processing conditions. Second, sanitary valves are designed to be completely cleanable. No hidden nooks or crannies for bacteria to thrive and grow.

The right valve selection is critical to proper functionality of your process and to minimize down-time in your line. SPX Flow offers a wide range of valves that ensure compliance, performance and cleanability.

Butterfly Valves offer great durability and ease of use for a wide range of services.

Ball valves offer great economy and durability for a wide range of applications that do not require clean-in-place (CIP) service. They are easy to install and maintain.

Ball valves offer a great economy and durability for a wide range of applications that do not require clean-in-place (CIP) service. They are easy to install and maintain.

Butterfly Valves offer great durability and ease of use for a wide range of services.