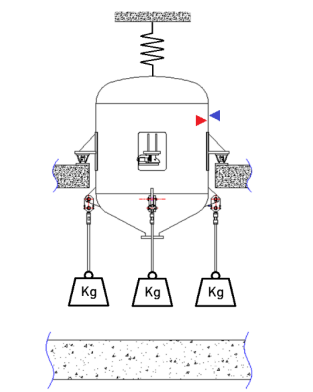

Attached pipes are the crucial difference between tank scales and other industrial scales such as platforms. As a tank scale is loaded, it deflects downwards pulling with it the attached pipes which apply an increasing upward force. This reduces the amount of weight registered by the load cells effectively reducing the sensitivity of the scale. Metrology can be seriously impacted if the scale is not designed and calibrated correctly.

Ideally, calibration is done by applying test weights which exercise the scale support-structure and piping, thus simulating normal scale operation exactly.

This exposes the piping effect on scale sensitivity allowing it to be accounted for in the calibration process, something that cannot be achieved with any form of electrical or theoretical calibration. However, test-weight calibration can be difficult and time-consuming. Additionally, test weights are expensive and may not be available, especially for higher-capacity scales.

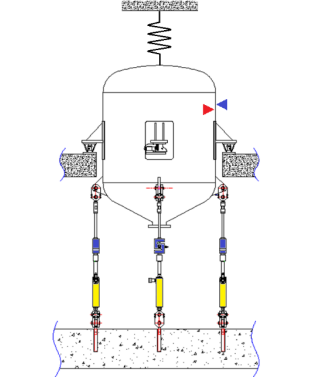

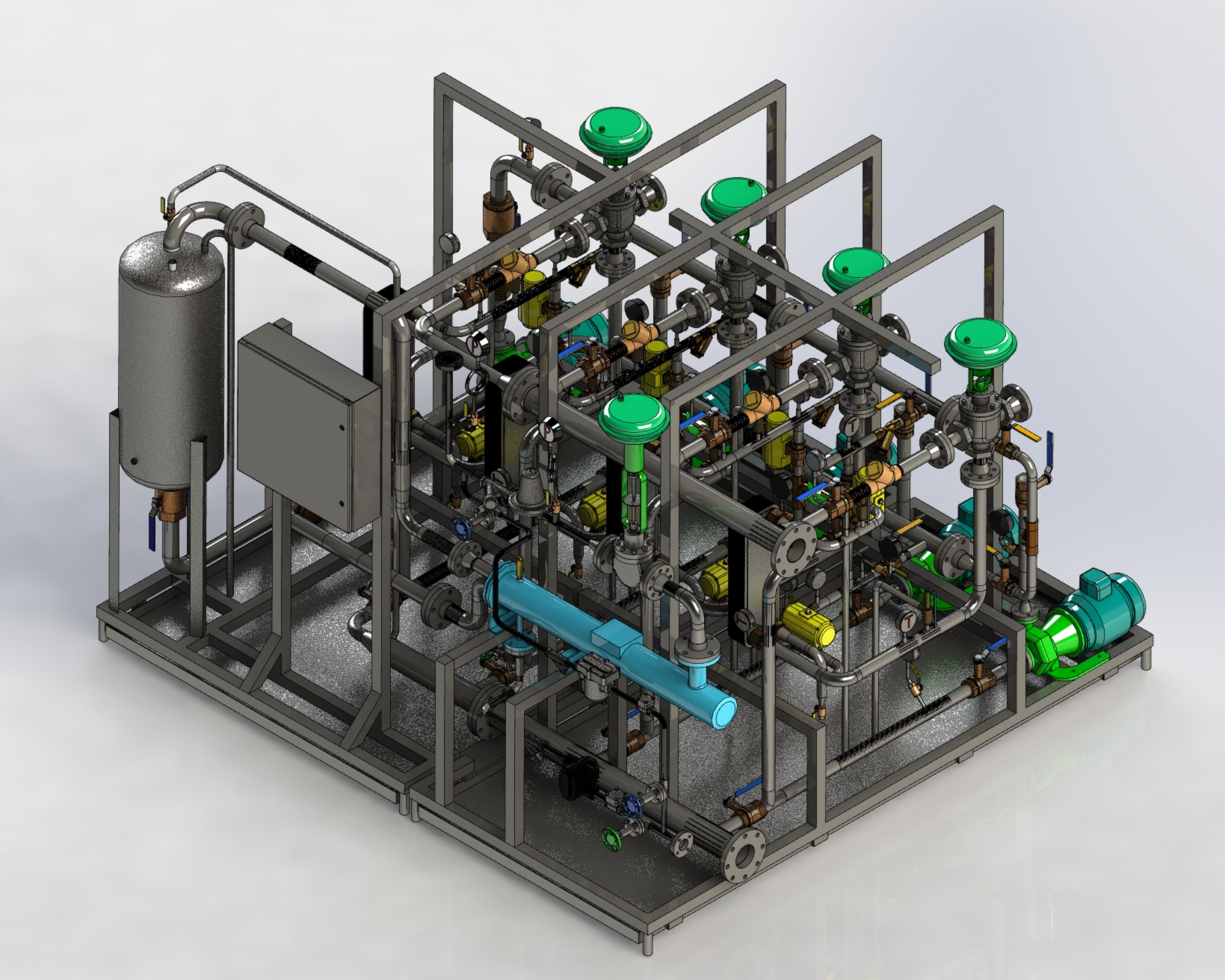

One to four RapidCal modules can be used, depending on the scale arrangement. They attach between anchor points on the scale and on the foundation directly below, using special hardware and threaded rod to adjust length. A hand-operated pump causes the hydraulic cylinders to retract, thus applying the downward force to the tank via the reference load cells. These load cells are connected to a separate terminal which monitors the process and provides the total load applied for calibration and/or adjustment.

The RapidCal method uses tension hydraulic cylinders to create the downward force that is measured by reference load cells. The equipment is modular; one to four calibration modules can be used depending on tank design and capacity.

The RapidCal method uses tension hydraulic cylinders to create the downward force that is measured by reference load cells. The equipment is modular; one to four calibration modules can be used depending on tank design and capacity.

There are three main steps during design and installation:

1. Select the number and capacity of the RapidCal modules to be used.

2. Select the type and placement of T-anchor points on the tank.

3. Select the type and placement of B-anchor points on the floor/base.

General Considerations

- Forces on anchor points.

- Lugs used also for lifting.

- Do not interfere with the scale’s weigh modules.

- Symmetrical placement of anchor points.

- Vertical alignment of anchor points.

- Calibration of tanks on a deflecting structure.

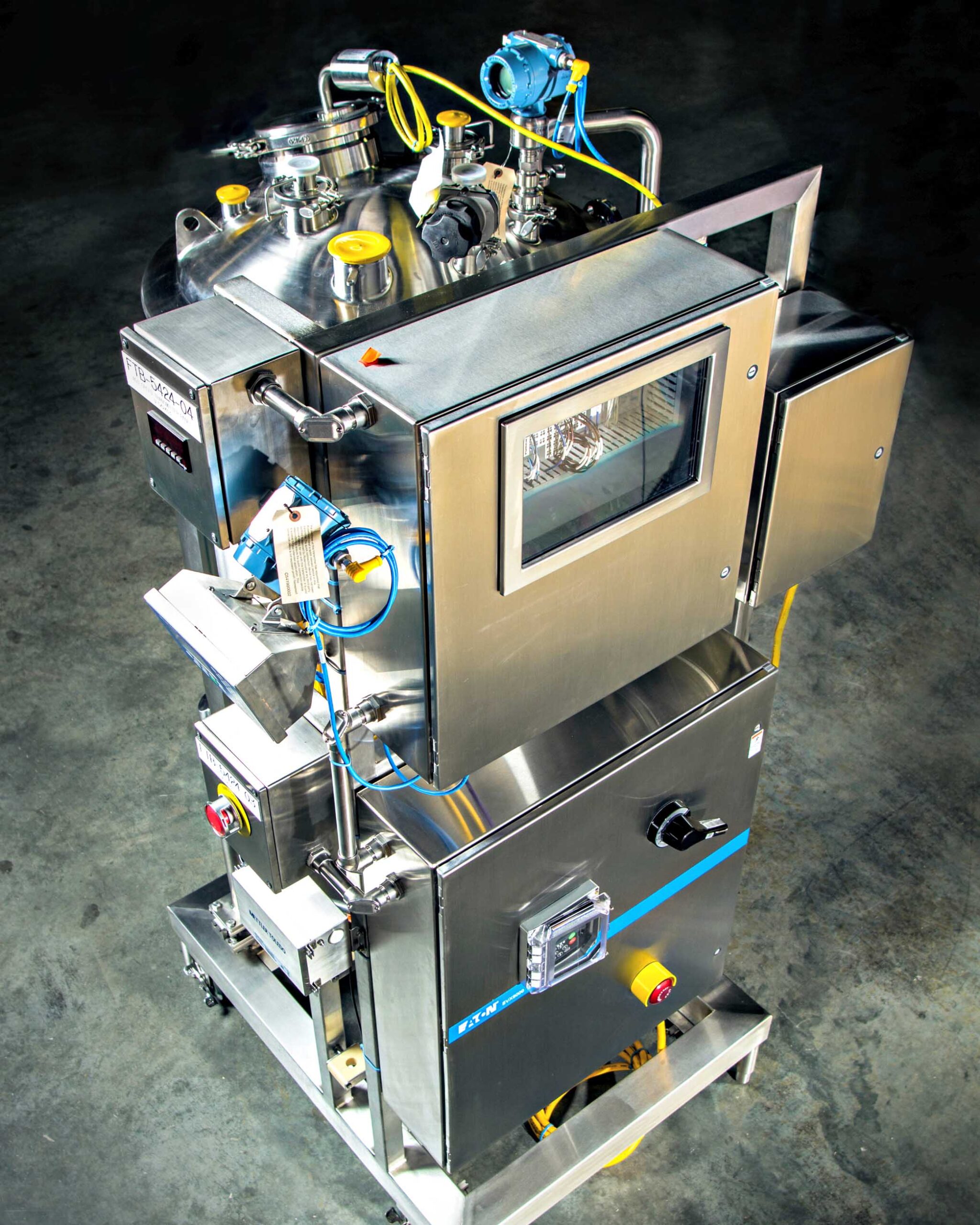

Why a Service Program Matters

- Reducing Downtime.

- Regulating Maintenance Budgets.

- Extending the Lifetime of Your Weighing Equipment.

Is it Necessary to Partner with My Equipment Manufacturer?

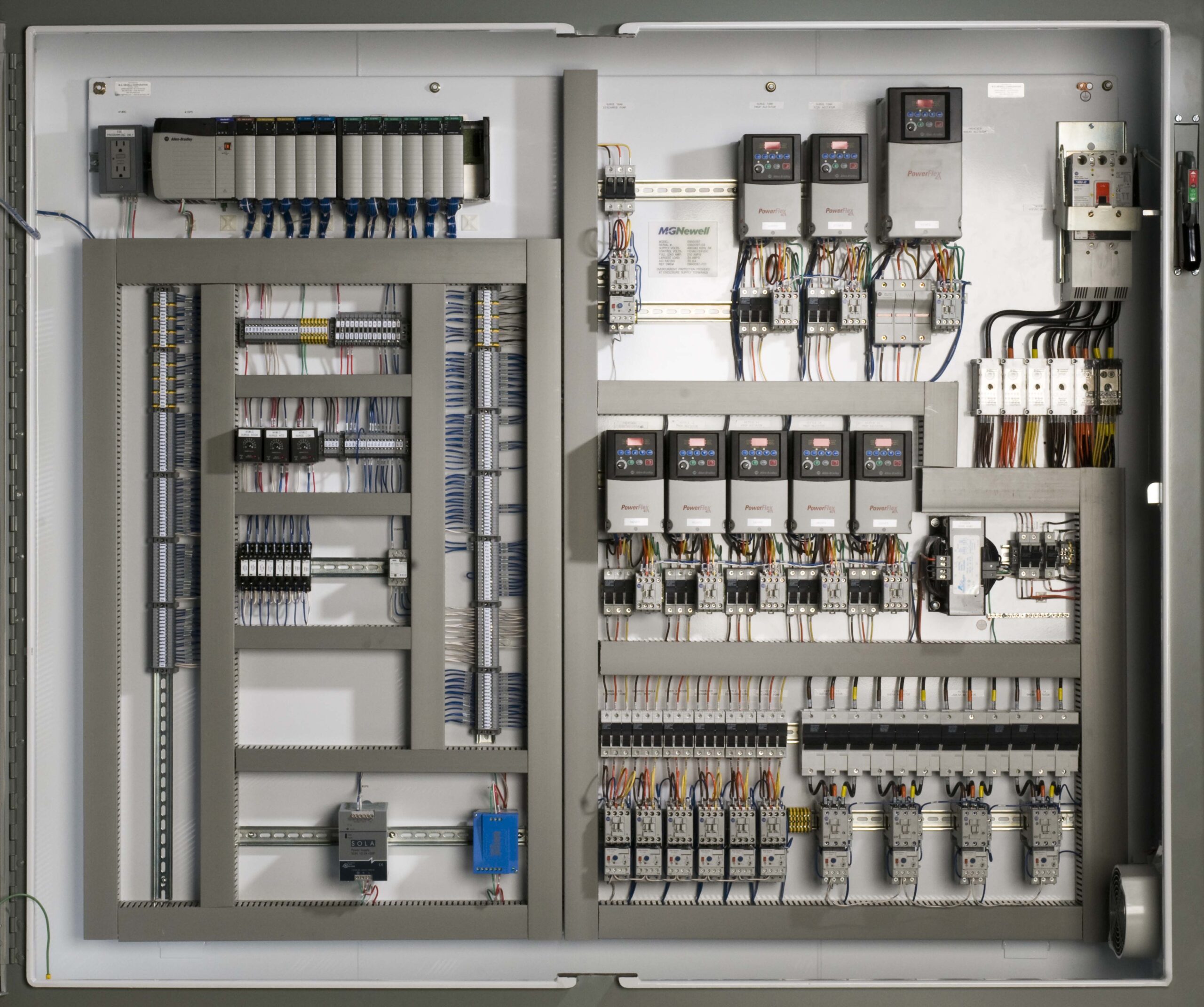

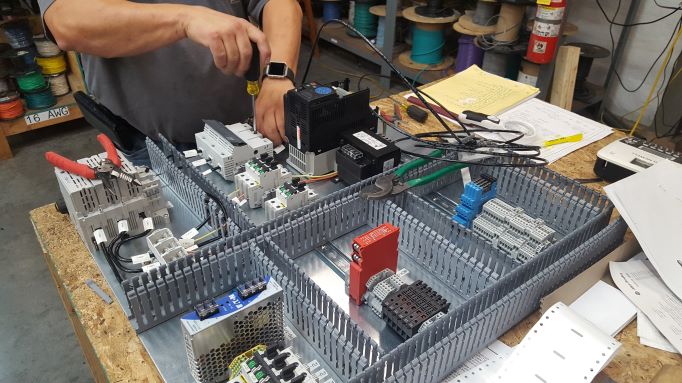

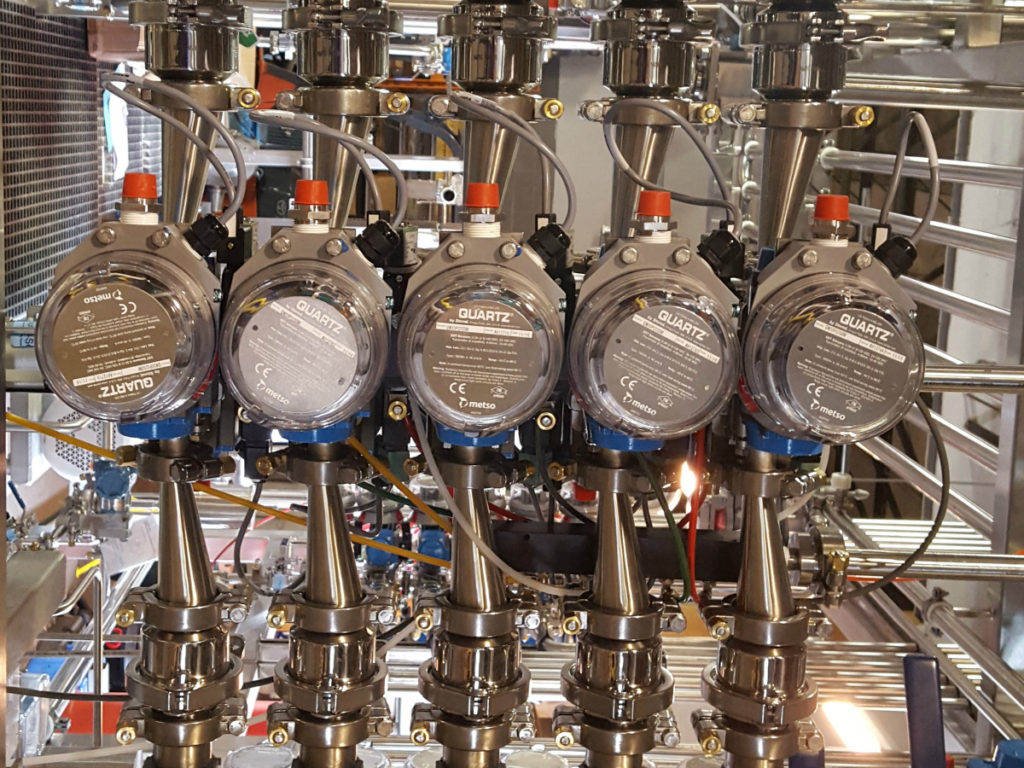

• Expert service engineers trained and equipped by the manufacturer.

• Factory-designed service procedures.

• Spare parts that meet manufacturer specifications and third-party approvals.

• Fast turnaround times due to easy access to parts and support.

How Do I Benefit from Setup and Configuration Services?

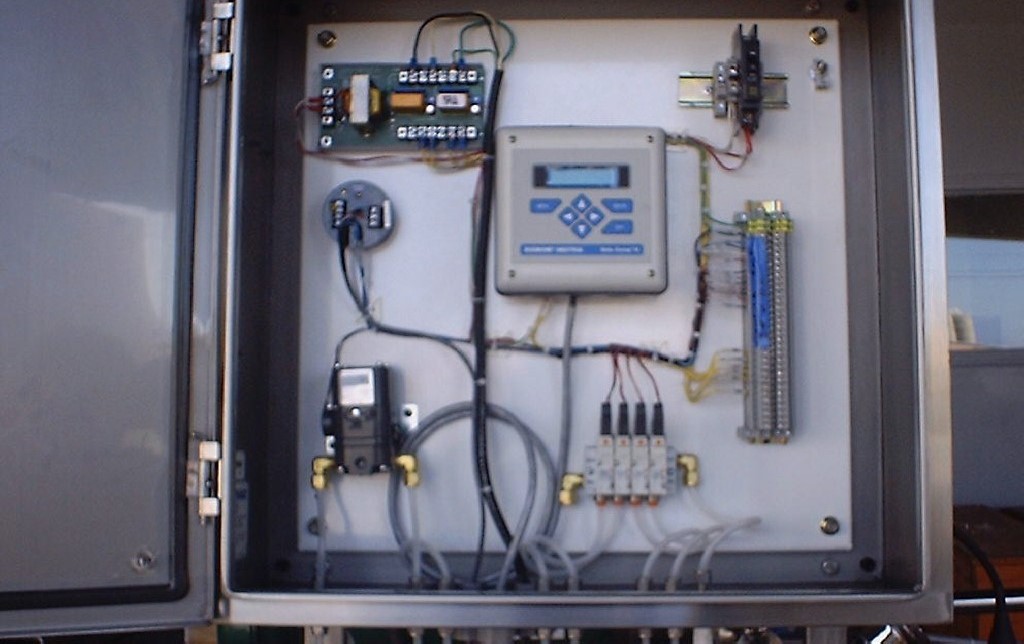

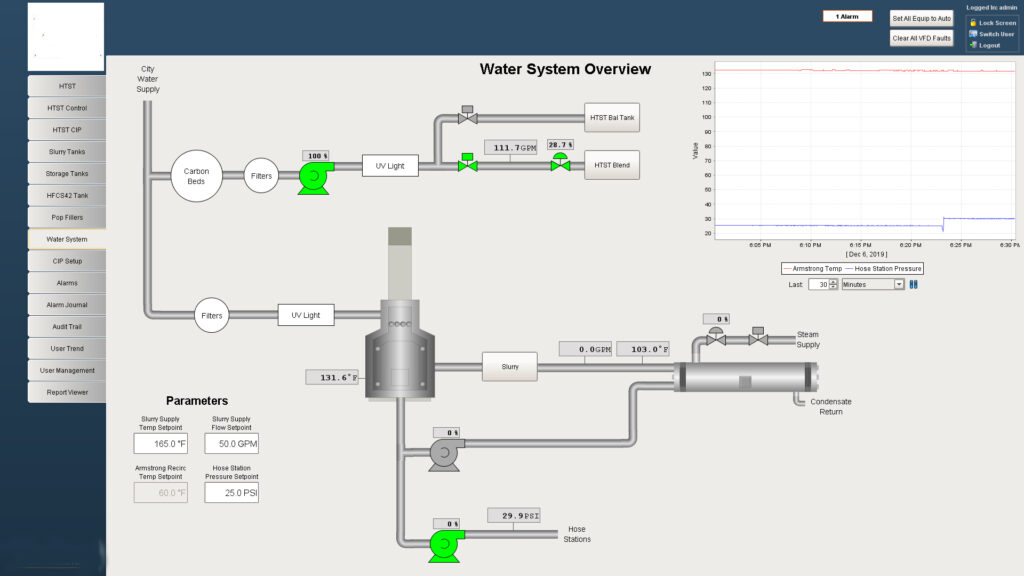

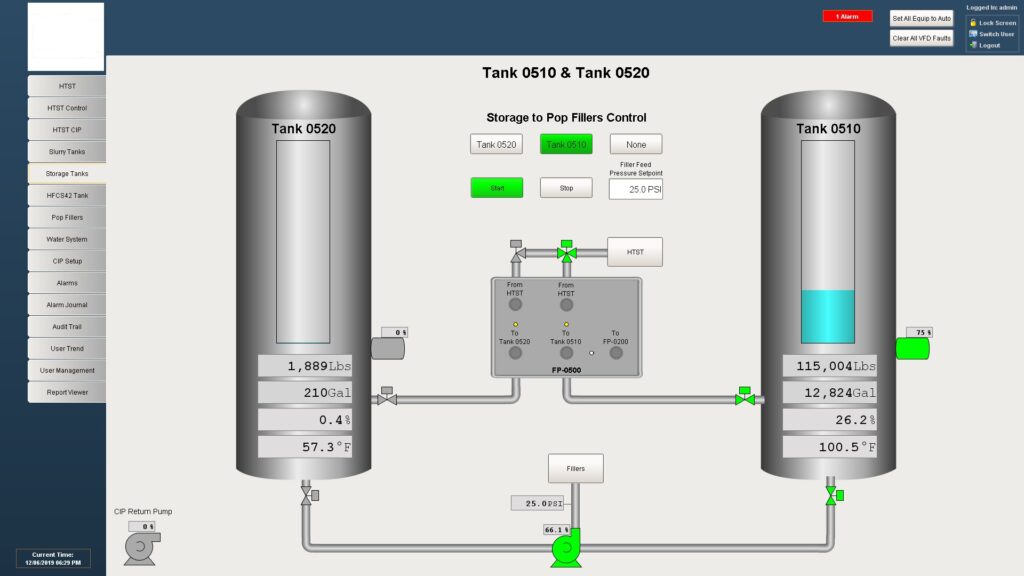

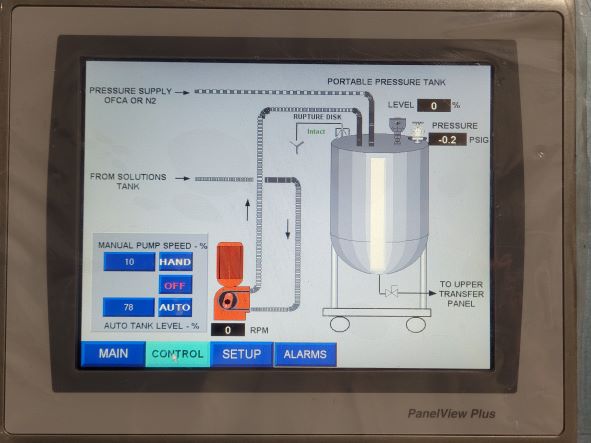

• Setup of weighing parameters to meet process and compliance requirements.

• Interfacing to data acquisition and automation systems.

• Tailoring of workflows to maximize operator productivity.

• Configuring of input and output behavior.

• Documentation of installation activities and initial performance.

For more information, visit our website: www.mgnewell.com and www.newellautomation.com.