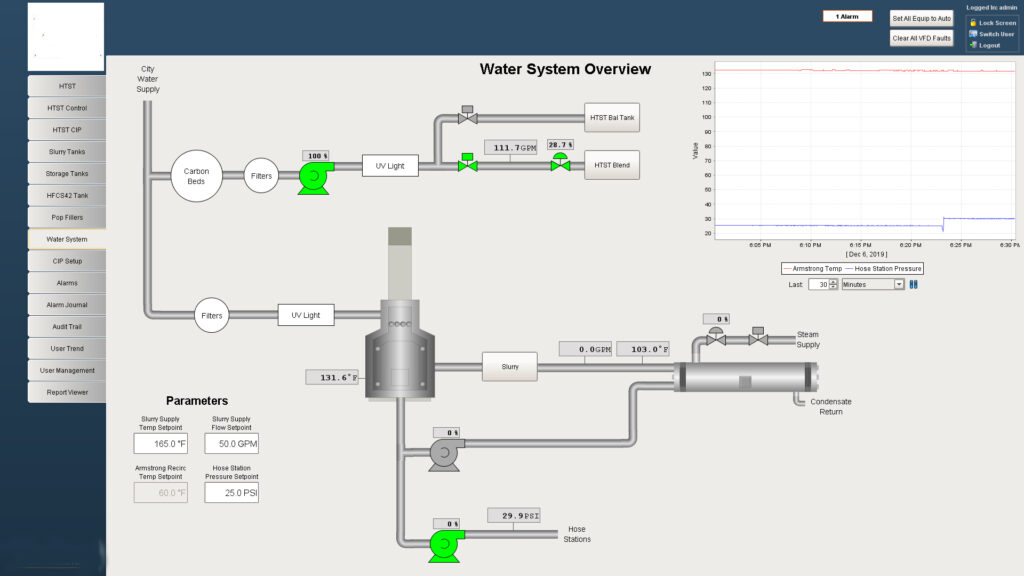

Enhanced Heat Transfer Efficiency:

Plate Heat Exchangers utilize corrugated plates with large surface areas to facilitate efficient heat transfer between two fluid streams. The turbulent flow created by the plates ensures optimal heat exchange, allowing for precise temperature control. This results in faster heating and cooling times, reducing processing cycles and increasing production throughput. Improved efficiency also translates to energy savings, making PHEs a cost-effective solution for food and beverage processors.

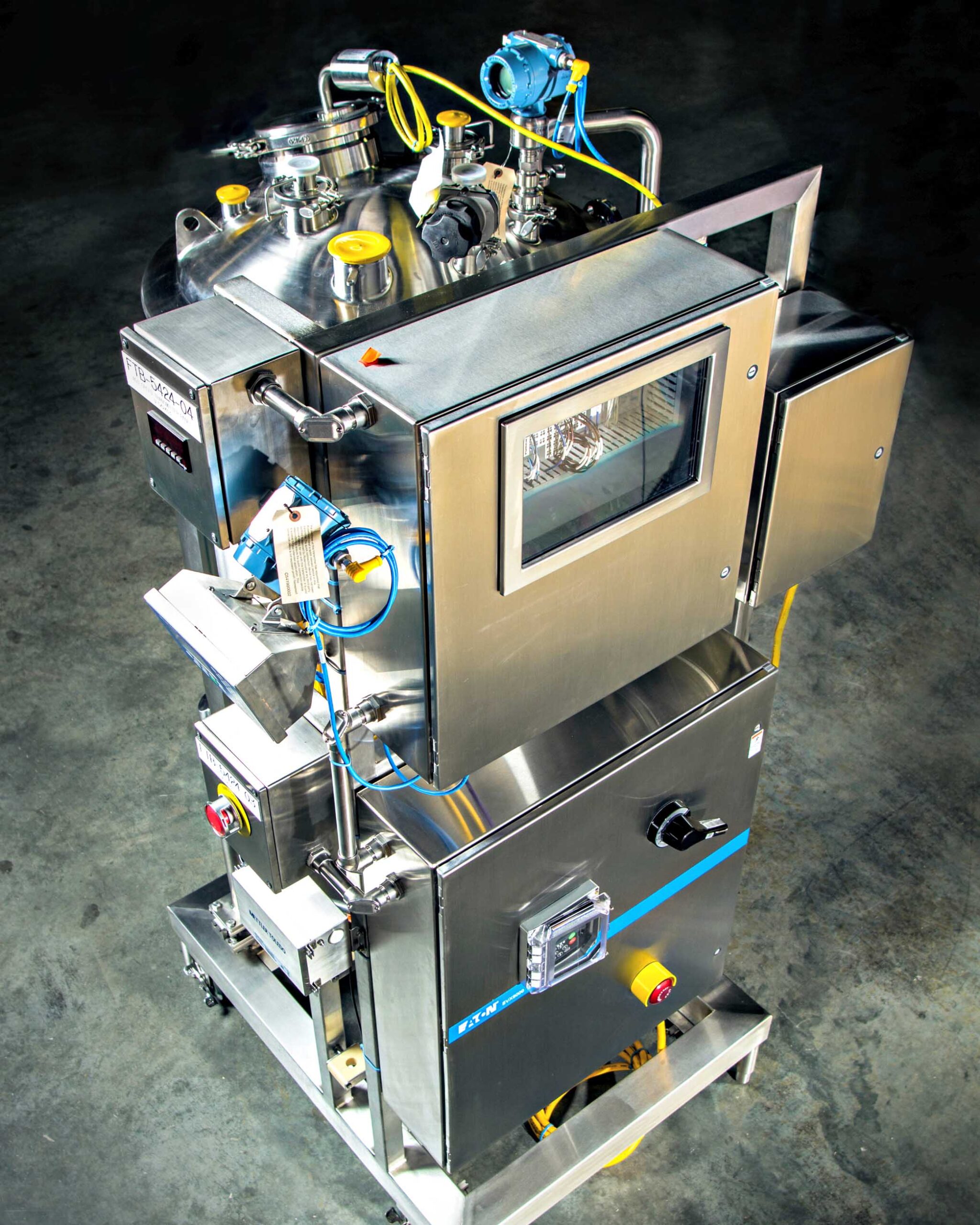

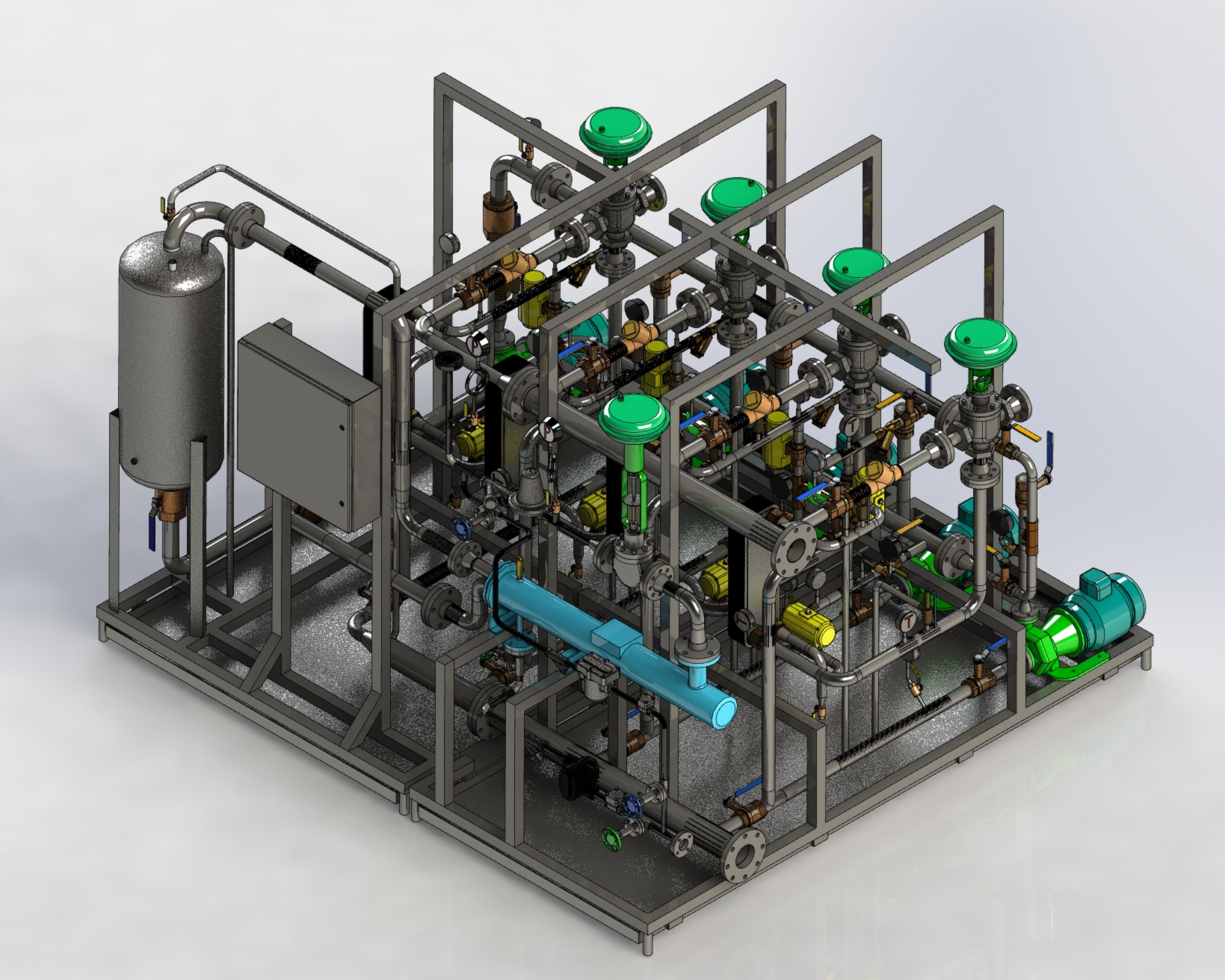

Compact Design and Space Optimization:

Compared to traditional heat exchangers, Plate Heat Exchangers have a compact footprint. Their efficient use of space allows for greater flexibility in plant layout and optimal utilization of available floor space. This is particularly beneficial for food and beverage manufacturers operating in space-constrained environments. The compact design also simplifies installation and maintenance, reducing downtime and improving overall operational efficiency.

Flexible and Versatile Applications:

Plate Heat Exchangers are highly versatile and can be used for various applications in the food and beverage industry. From pasteurization and sterilization to cooling and heating processes, PHEs excel in delivering precise temperature control across a wide range of food and beverage products. They can handle different viscosities and can be easily adapted to suit specific process requirements, ensuring consistency and quality throughout production.

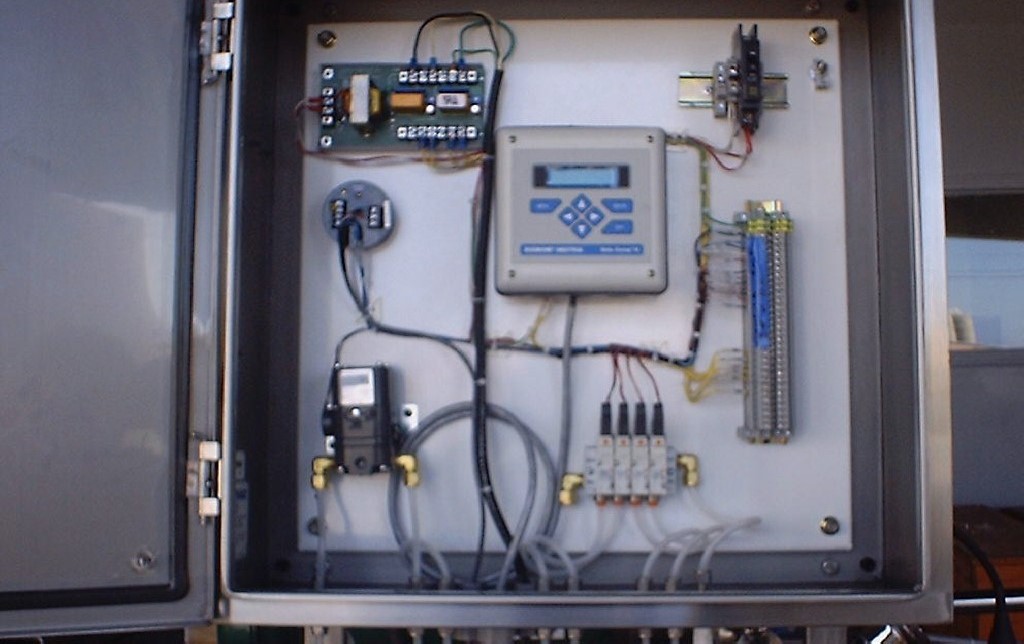

Hygienic and Sanitary Design:

Maintaining the highest standards of hygiene is paramount in the food and beverage industry. Plate Heat Exchangers are designed with sanitary requirements in mind, featuring smooth plate surfaces that are easy to clean and sterilize. By disassembling, plate design allows for thorough cleaning, reducing the risk of contamination and ensuring food safety compliance. This design feature also facilitates regular maintenance and inspection, contributing to overall plant hygiene and product integrity.

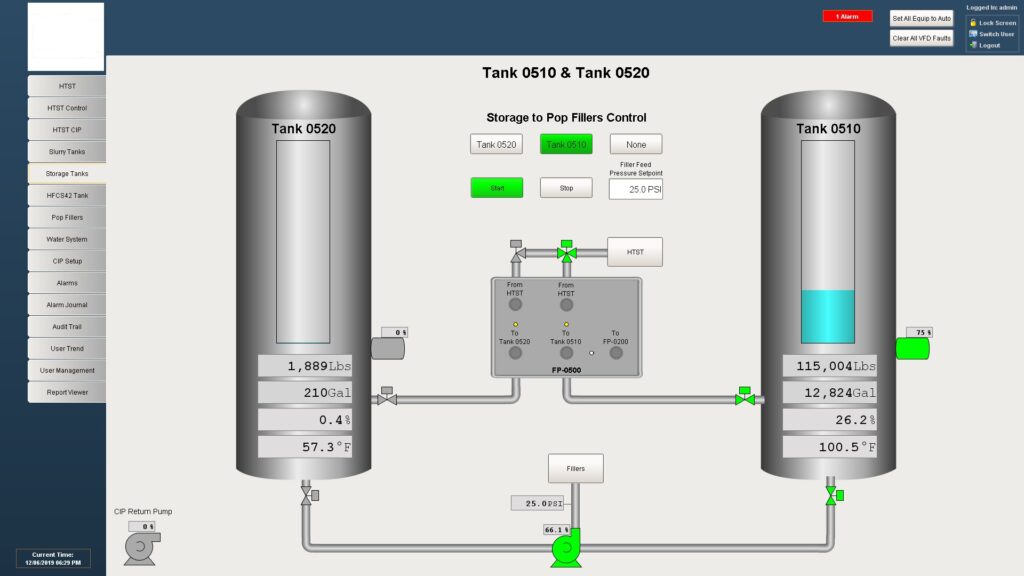

Reduced Cross-Contamination Risk:

In food and beverage processing, preventing cross-contamination is essential to ensure product quality and safety. Plate Heat Exchangers are designed to minimize the risk of cross-contamination by providing efficient separation between the two fluid streams. The use of gaskets and proper sealing ensures there is no mixing or transfer of unwanted substances, protecting the integrity of the product and maintaining strict quality control standards.

With their compact design, precise temperature control, and hygienic features, PHEs contribute to improved productivity, reduced energy consumption, and consistent product quality. By adopting Plate Heat Exchangers in food and beverage processing, manufacturers can optimize their operations, meet stringent sanitary standards, and deliver high-quality products to consumers.

For more information, visit our website: www.mgnewell.com and www.newellautomation.com.