Optimized tank cleaning is an opportunity for significant savings, although often overlooked.

By optimizing your tank cleaning you can:

- Decrease cleaning times by 70%

- Reduce water and chemical usage by 70-80%

- Reduce or eliminate confined space entry by 100%

- Achieve cleaning effectiveness of 100%

Remember, its not just safer and cleaner tanks you are offering – you are giving them more time, and time is money!

Justify their purchase

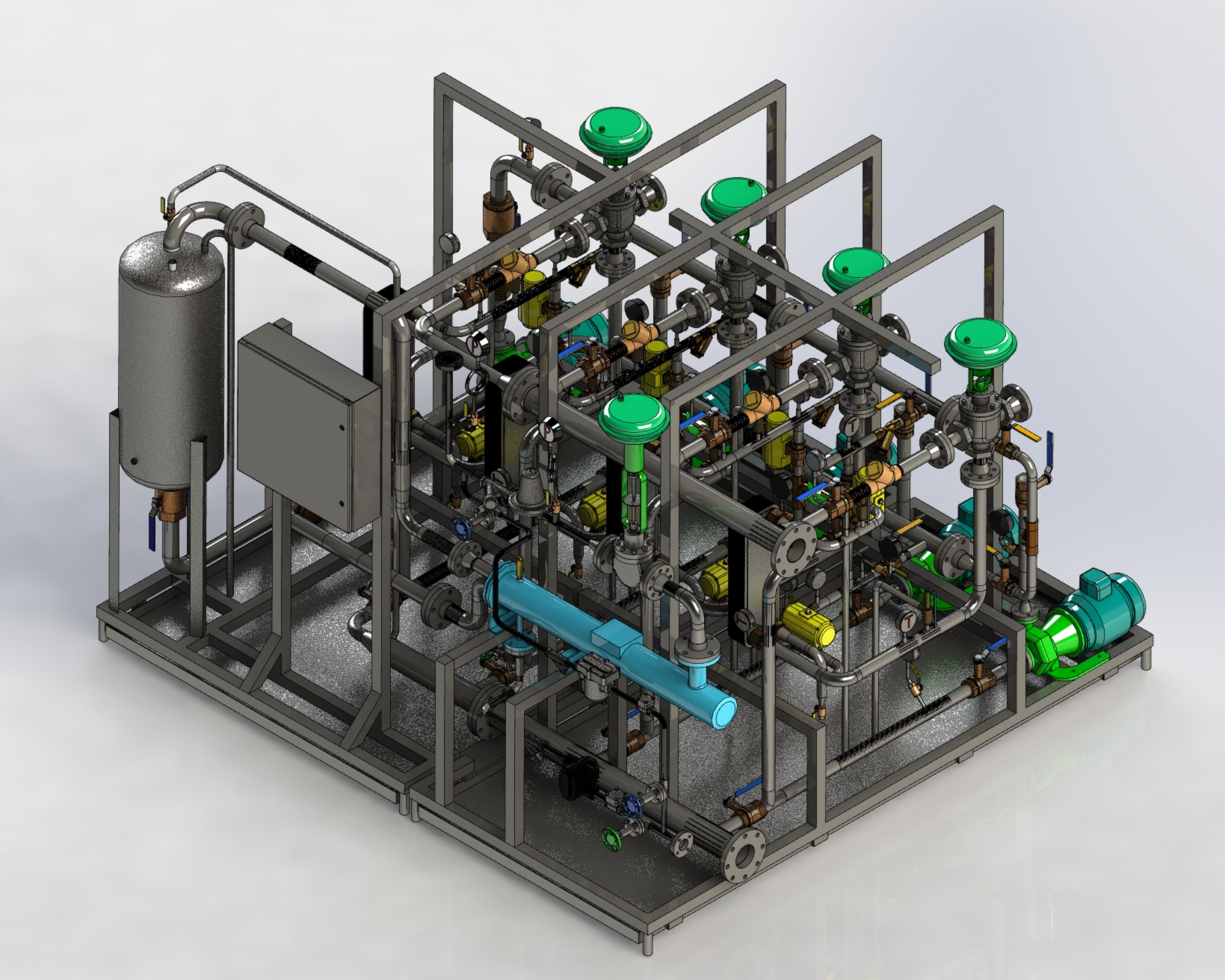

Easy to cleaning application, such as :

Operating pressure :

30-43 PSI (2-3 bar)

Tank sizes :

50-2.500 gallons

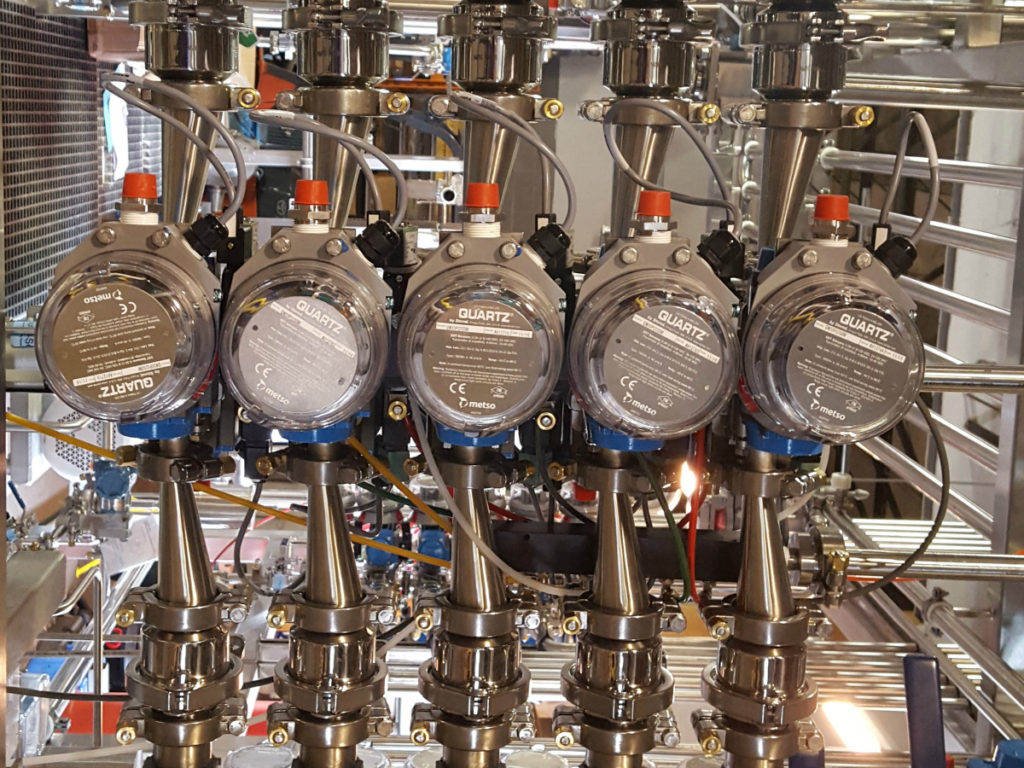

Easy-difficult to cleaning application, such as :

Operating pressure :

30-43 PSI (2-3 bar)

Tank sizes :

50-10.000 gallons

Difficult to very difficult to cleaning application, such as :

Operating pressure :

72-116 PSI (5-8 bar)

Tank sizes :

5.000-40.000+ gallons

Static Spray Ball

- Consumption of water/chemical: High water / chemical consumption used, due to low cleaning efficiency

- Cleaning efficiency: Low cleaning efficiency, cleans in spot only and cascading water

- Cleaning time: Long cleaning time = less production time

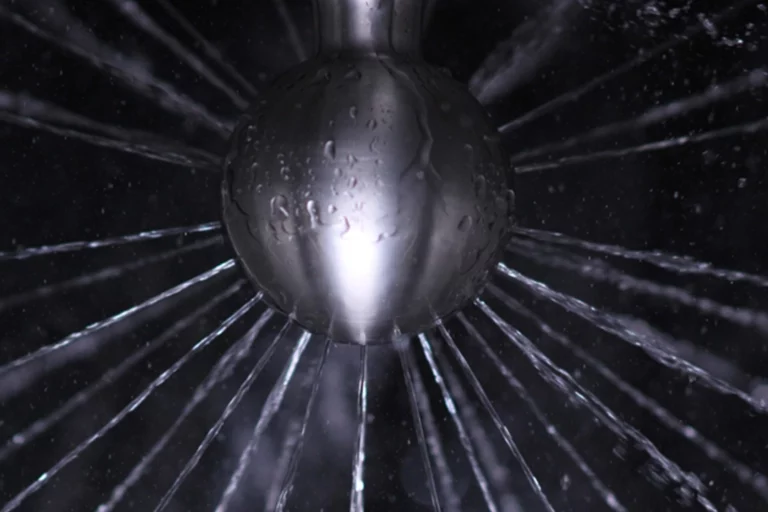

Rotary Spray Head

- Consumption of water/chemical: Medium consumption

−30-40% less compared to a traditional spray ball

- Cleaning efficiency: Medium cleaning efficiency

−10 times more wall shear stress compared to spray ball

- Cleaning time: Medium

−Up to 30% reduced cleaning time compared to spray ball

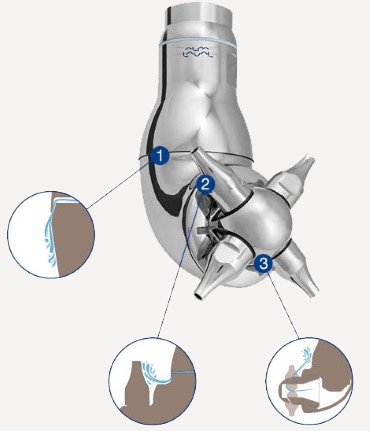

Rotary Jet Head

- Consumption of water/chemical: Low consumption

−70% less compared to a traditional spray ball

−20-30% less compared to a rotary spray head

- Cleaning efficiency :

− High cleaning efficient, high impact tank cleaning.

− 100 times more wall shear

stress compared to traditional spray ball

- Cleaning time : Fast cleaning = more production time

−50-70% faster cleaning compared to traditional spray ball

For more information, visit our website: www.mgnewell.com and www.newellautomation.com.